Description

Zirconium n-Propoxide: A Versatile Building Block in Advanced Materials Science

In the intricate world of advanced materials, the choice of precursor compounds is paramount. These are the chemical starting points that dictate the purity, structure, and ultimate performance of the final product. One such pivotal precursor, widely recognized for its versatility and reactivity, is Zirconium n-Propoxide, often abbreviated as Zr(OnPr)4 or Zr(OCH2CH2CH3)4.

What is Zirconium n-Propoxide?

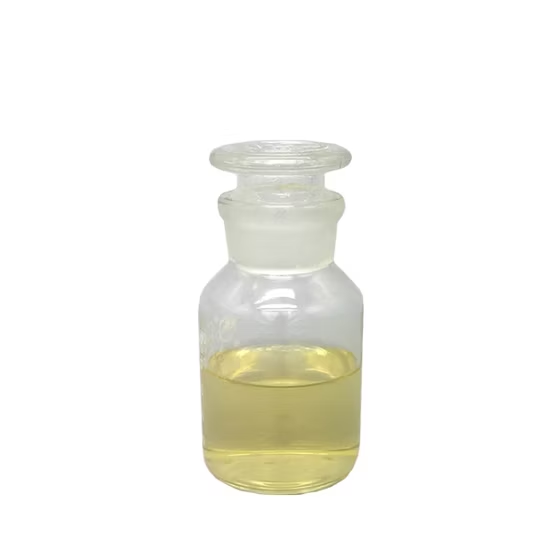

Zirconium n-Propoxide is an organometallic compound belonging to the family of metal alkoxides. It consists of a central zirconium (Zr) atom bonded to four n-propoxide (–OCH2CH2CH3) groups. At room temperature, it typically presents as a clear, colorless to pale yellow liquid, highly soluble in various organic solvents. Its key characteristic, and the basis for many of its applications, is its high reactivity with water (hydrolysis) and other protic compounds.

Synthesis

Zirconium alkoxides, including the n-propoxide, are commonly synthesized by the reaction of zirconium tetrachloride (ZrCl4) with n-propanol, often in the presence of a base (like ammonia or sodium metal) to neutralize the generated hydrochloric acid and drive the reaction to completion:

ZrCl4 + 4 n-PrOH + 4 NH3 → Zr(OPr)4 + 4 NH4Cl

The product is then typically purified through distillation or recrystallization.

Key Properties and Applications

The unique chemical properties of Zirconium n-Propoxide make it an indispensable precursor in a wide range of high-tech applications:

- Sol-Gel Process: This is arguably its most significant application. The sol-gel method is a chemical route to produce ceramic or glass materials from a solution (sol) that gradually evolves into a gel network. Zirconium n-propoxide readily undergoes hydrolysis and condensation reactions in the presence of water, forming a zirconium hydroxide gel, which upon calcination (heating) transforms into high-purity zirconium dioxide (ZrO2) or other zirconium-containing ceramics.

- Applications:

- Coatings: Anti-reflective, optical, wear-resistant, corrosion-resistant, and biocompatible coatings for medical implants.

- Catalysts: Zirconia (ZrO2) is an excellent solid acid/base catalyst and support material for various chemical reactions, including esterification, polymerization, and environmental catalysis.

- Sensors: Used in oxygen sensors, gas sensors, and biosensors.

- Electronic Materials: High-k dielectric layers in semiconductors, ferroelectrics (e.g., PZT – lead zirconate titanate), and ceramic capacitors.

- Fuel Cells: Components in solid oxide fuel cells (SOFCs).

- Applications:

- Chemical Vapor Deposition (CVD) and Atomic Layer Deposition (ALD): Due to its moderate volatility and thermal stability, Zirconium n-propoxide can be used as a precursor in CVD and ALD processes to deposit thin films of zirconia or zirconium-containing mixed oxides. This method allows for precise control over film thickness and composition, crucial for microelectronics.

- Applications: Gate dielectrics in advanced semiconductor devices, dielectric layers in memory chips, and protective coatings.

- Ceramic Precursor: Beyond the sol-gel route, Zirconium n-propoxide can be directly pyrolyzed (decomposed by heat) to yield ultra-fine, high-purity zirconia powders, which are then used in advanced ceramics for their excellent mechanical properties, high melting point, and chemical inertness.

- Organic Synthesis and Catalysis: Zirconium alkoxides can act as Lewis acids and are sometimes employed as catalysts or reagents in various organic transformations, such as esterification, transesterification, and polymerization reactions.

Advantages as a Precursor

- High Purity: Unlike traditional methods, chemical precursors like zirconium n-propoxide can yield materials with exceptional purity, which is critical for high-performance applications.

- Controllable Stoichiometry: It allows for precise control over the elemental composition of the final material, especially in mixed-metal oxides.

- Lower Processing Temperatures: Sol-gel and CVD methods often operate at lower temperatures compared to conventional ceramic manufacturing, enabling the use of diverse substrates.

- Versatility: Can be tailored to produce a wide array of zirconium-based materials with different morphologies (powders, thin films, monolithic structures).

Safety and Handling

Zirconium n-propoxide is a reactive compound. It is typically a flammable liquid and reacts vigorously with water, releasing heat and potentially flammable organic vapors (propanol). Therefore, it must be handled under an inert atmosphere (nitrogen or argon) and away from moisture. Proper personal protective equipment (PPE) and adequate ventilation are essential when working with this chemical.

Conclusion

Zirconium n-Propoxide stands as a cornerstone in the synthesis of advanced zirconium-based materials. Its unique reactivity, particularly its controlled hydrolysis, makes it an ideal precursor for the sol-gel process, CVD, and the production of high-purity ceramics. As material science continues to push the boundaries of performance and functionality, the demand for sophisticated precursors like zirconium n-propoxide will undoubtedly remain high, driving innovation in fields ranging from electronics and optics to energy and biomedicine.

Reviews

There are no reviews yet.