Description

The Versatile World of Thin Gauge Sheets: Material, Applications, and Considerations

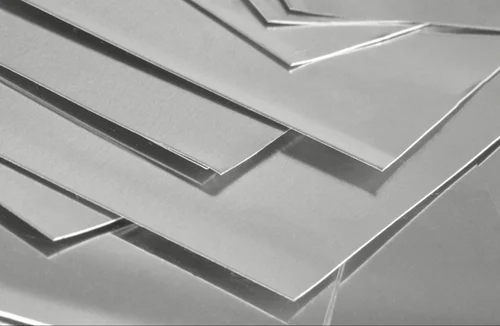

Thin gauge sheets, often overlooked, are a cornerstone of countless industries and everyday applications. These sheets, characterized by their small thicknesses, offer a unique combination of flexibility, formability, and cost-effectiveness. This article delves into the world of thin gauge sheets, exploring the materials they are made from, their diverse applications, and essential considerations when choosing and working with them.

What are Thin Gauge Sheets?

The term “thin gauge” is relative, often depending on the material in question. Generally, it refers to sheets with a thickness of fractions of an inch or millimeter. Unlike thicker plates used for structural support, thin gauge sheets are favored where weight reduction, ease of shaping, and cost are primary concerns.

Material Matters: A Variety of Options

Thin gauge sheets are available in a wide range of materials, each offering distinct properties:

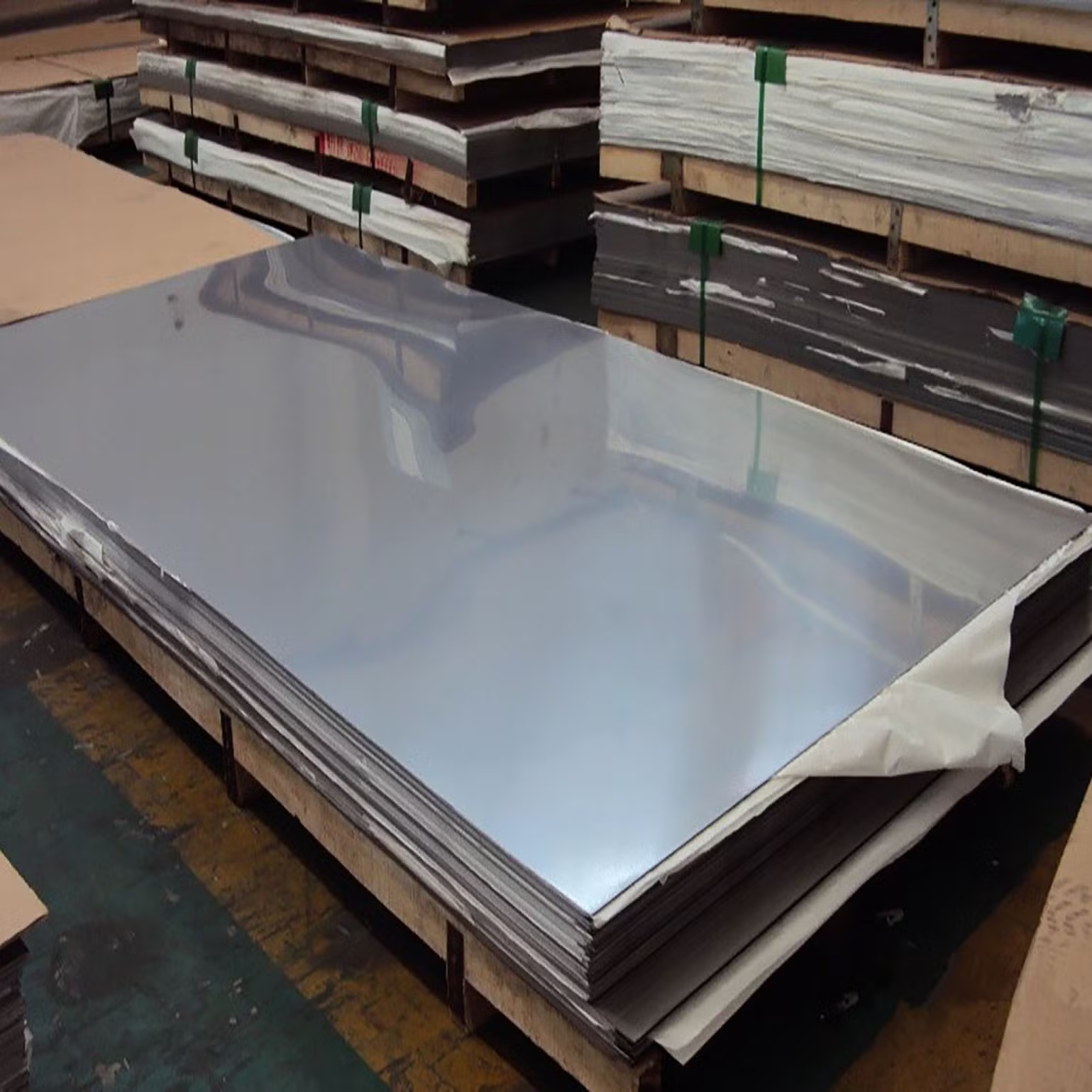

- Steel: This is perhaps the most common material, offering strength, durability, and weldability. Different steel alloys, such as carbon steel, stainless steel, and galvanized steel, cater to specific needs regarding corrosion resistance, hardness, and formability.

- Aluminum: Lightweight and corrosion-resistant, aluminum thin gauge sheets are popular in aerospace, automotive, and packaging applications. They are also highly recyclable, contributing to sustainability.

- Copper: Known for its excellent electrical and thermal conductivity, copper thin gauge sheets are essential in electronics, electrical wiring, and roofing.

- Brass: A copper-zinc alloy, brass offers good corrosion resistance, aesthetic appeal, and acoustic properties, making it suitable for decorative elements, musical instruments, and plumbing components.

- Titanium: Exceptionally strong and lightweight with superior corrosion resistance, titanium thin gauge sheets are used in demanding environments such as aerospace, medical implants, and chemical processing.

- Plastics: Various plastics, including PVC, polycarbonate, and acrylic, are available as thin gauge sheets. They are often chosen for their affordability, ease of fabrication, and resistance to chemicals and moisture.

Applications Across Industries:

The versatility of thin gauge sheets is evident in their widespread applications:

- Automotive: Vehicle body panels, interior trim, heat shields, and exhaust components often utilize thin gauge steel and aluminum for weight reduction and fuel efficiency.

- Aerospace: Aircraft skin, interior components, and structural elements benefit from the high strength-to-weight ratio of thin gauge aluminum and titanium.

- Construction: Roofing, cladding, ductwork, and gutters employ thin gauge steel, aluminum, and plastics for weather protection and aesthetics.

- Electronics: Enclosures, PCB shields, and connectors rely on the conductivity and formability of thin gauge copper, aluminum, and steel.

- Packaging: Food cans, beverage containers, and other packaging solutions utilize thin gauge aluminum and steel for protection, preservation, and recyclability.

- Medical: Surgical instruments, implants, and medical devices exploit the biocompatibility and corrosion resistance of thin gauge titanium and stainless steel.

- General Manufacturing: Appliances, furniture, and various consumer products incorporate thin gauge sheets for structural support, aesthetic appeal, and functional features.

Considerations When Choosing and Working with Thin Gauge Sheets:

Selecting and utilizing thin gauge sheets requires careful consideration of several factors:

- Material Selection: The choice of material depends on the specific application requirements, including strength, weight, corrosion resistance, formability, and cost.

- Gauge (Thickness): Selecting the appropriate gauge is crucial for meeting the desired strength, stiffness, and durability requirements. Thinner gauges are more flexible but less robust, while thicker gauges offer greater strength but are less easily formed.

- Forming Techniques: Thin gauge sheets can be formed using various methods, including bending, stamping, deep drawing, and roll forming. Choosing the appropriate technique depends on the material, shape complexity, and production volume.

- Joining Methods: Welding, riveting, adhesives, and mechanical fasteners are common methods for joining thin gauge sheets. The chosen method must ensure sufficient strength and durability without damaging the material.

- Surface Finish: Surface treatments, such as painting, powder coating, anodizing, and plating, can enhance the aesthetic appeal, corrosion resistance, and performance of thin gauge sheets.

- Tooling and Equipment: Working with thin gauge sheets often requires specialized tooling and equipment to prevent damage and ensure accurate forming and fabrication.

Conclusion:

Thin gauge sheets are a vital material in countless applications, offering a compelling combination of versatility, affordability, and performance. By understanding the different materials available, their properties, and the considerations involved in their selection and fabrication, engineers and manufacturers can effectively leverage the benefits of thin gauge sheets to create innovative and efficient solutions. As technology advances and the demand for lightweight and sustainable materials grows, the role of thin gauge sheets will only continue to expand.

Reviews

There are no reviews yet.