Description

Silica Aerogels: Capturing Air in a Solid Embrace

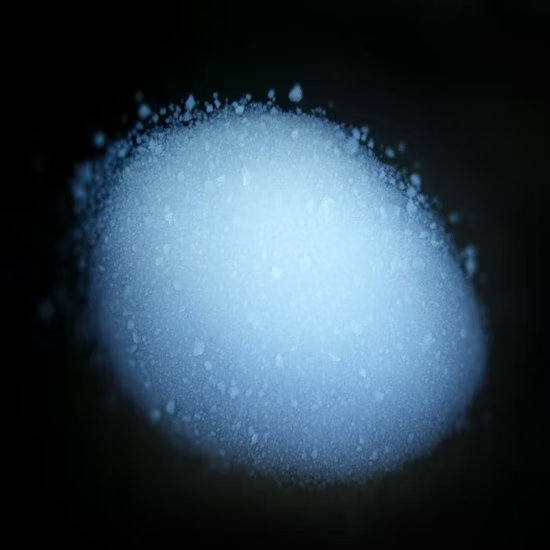

Silica aerogels are arguably one of the most fascinating and technologically promising materials ever synthesized. Often referred to as “frozen smoke” or “solid air,” these ethereal substances boast an extraordinary combination of properties that make them suitable for a wide range of applications, from insulation to spacecraft exploration. But what exactly are silica aerogels, and what makes them so special?

The Essence of Aerogels: A Dance Between Solid and Air

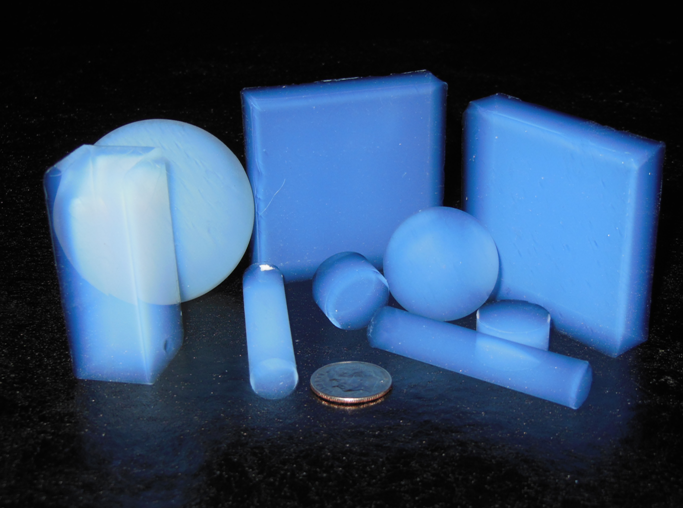

At their core, aerogels are highly porous, solid materials derived from a gel, where the liquid component has been replaced with a gas. This process, typically using supercritical drying, prevents the collapse of the gel structure that would occur with traditional evaporation. The resulting material retains the solid network but occupies it with a vast network of interconnected pores filled with air.

Silica aerogels, in particular, are based on silica (silicon dioxide), the same material that constitutes sand and glass. However, unlike these dense counterparts, silica aerogels are incredibly lightweight. In fact, they are among the lightest solid materials known to humankind, with densities ranging from just a few milligrams per cubic centimeter. This extreme low density is a direct result of their high porosity, often exceeding 90-99%.

A Symphony of Remarkable Properties:

The unique structure of silica aerogels gives rise to a remarkable array of properties, including:

- Exceptional Thermal Insulation: Aerogels are incredibly effective at blocking heat transfer. The tiny pores within the structure impede the movement of air (convection) and solid conduction, making them superior insulators compared to traditional materials like fiberglass or polystyrene. This makes them ideal for applications like building insulation, cryogenic storage, and high-performance clothing.

- High Surface Area: The extensive network of pores provides an enormous surface area within a small volume. This characteristic makes aerogels excellent candidates for applications requiring high adsorption rates, such as catalysts, filtration systems, and drug delivery.

- Low Dielectric Constant: Due to their high air content, aerogels exhibit a low dielectric constant, meaning they are poor conductors of electricity. This property is valuable in electronics applications, such as insulators in microchips and high-frequency circuits.

- Optical Transparency (in some cases): While some aerogels appear translucent, others can be fabricated to be remarkably transparent. This transparency, coupled with their insulating properties, opens doors to applications in windows and skylights that allow natural light while minimizing heat loss.

Applications Across Diverse Fields:

The exceptional combination of properties has propelled silica aerogels into diverse fields, including:

- Space Exploration: NASA has employed aerogels in missions like the Stardust spacecraft to capture interstellar dust particles without damaging them. Their low density and high surface area made them ideal for this task.

- Building Insulation: As mentioned earlier, aerogels are highly effective thermal insulators, making them valuable for improving energy efficiency in buildings. They can be incorporated into insulation panels, coatings, and even window glazings.

- Oil and Gas Industry: Aerogels can be used as adsorbents to clean up oil spills and remove pollutants from water. Their high surface area allows them to efficiently capture and retain these contaminants.

- Biomedical Applications: Aerogels are being explored for drug delivery systems, tissue engineering scaffolds, and biosensors. Their biocompatibility and tunable pore structure make them attractive for these applications.

- Electronics: Due to their low dielectric constant, aerogels are used as insulators in integrated circuits and high-frequency applications, enabling faster and more efficient electronic devices.

Challenges and Future Directions:

Despite their remarkable properties, the widespread adoption of silica aerogels faces certain challenges. One major obstacle is their relatively high production cost compared to conventional materials. Additionally, some aerogels can be brittle and susceptible to cracking.

However, ongoing research and development are addressing these challenges. Researchers are exploring new synthesis techniques to lower production costs and improve the mechanical strength of aerogels. This includes the development of flexible aerogels, composite aerogels, and aerogel-based coatings.

Conclusion: A Material with Limitless Potential

Silica aerogels represent a triumph of materials science, demonstrating the power of manipulating structure at the nanoscale to achieve remarkable properties. While challenges remain, the potential of these “frozen smoke” materials is undeniable. As production costs decrease and mechanical properties improve, silica aerogels are poised to play an increasingly important role in a wide range of applications, from energy efficiency and environmental remediation to space exploration and biomedical engineering. The future is undoubtedly bright for these extraordinary materials, promising innovation and advancements across numerous industries.

Reviews

There are no reviews yet.