Description

Polyvinyl Chloride Foam (PVC Foam): A Versatile Material Shaping Modern Industries

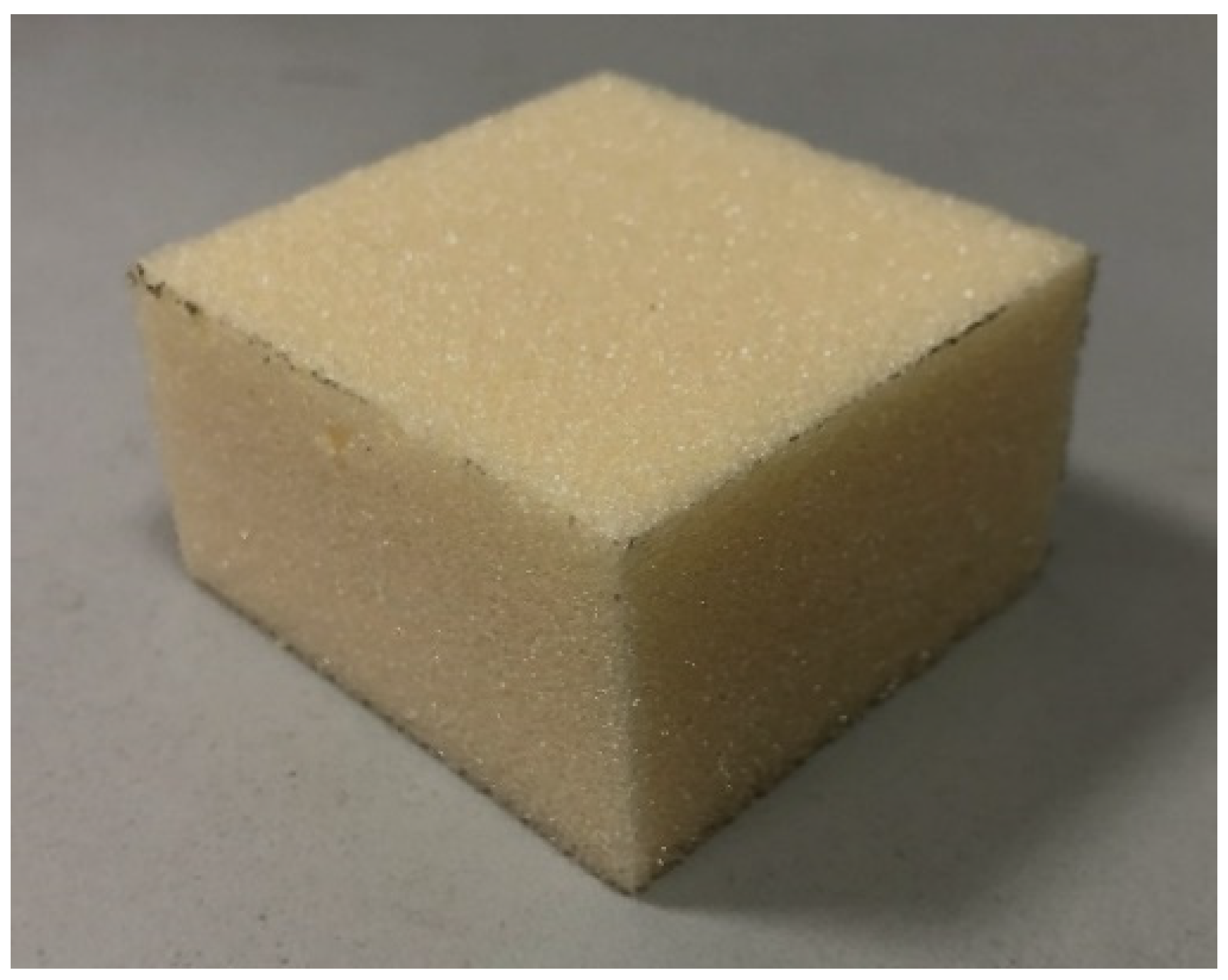

Polyvinyl Chloride Foam, more commonly known as PVC Foam, is a lightweight and durable closed-cell foam material derived from polyvinyl chloride (PVC). This versatile material has carved a significant niche in various industries due to its unique combination of properties, making it a popular alternative to traditional materials like wood, metal, and other plastics.

Understanding the Key Characteristics:

PVC Foam boasts a range of characteristics that contribute to its widespread adoption:

- Lightweight: Significantly lighter than solid PVC, PVC Foam reduces weight in applications where strength isn’t the primary concern. This is particularly advantageous in transportation and signage industries.

- Water Resistance: Being a closed-cell foam, PVC Foam is highly resistant to water absorption, making it ideal for outdoor applications and environments with high humidity.

- Chemical Resistance: Resistant to a wide range of chemicals, including acids, alkalis, and solvents, PVC Foam ensures longevity and reliability in demanding environments.

- Fire Retardant: Most PVC Foam formulations are inherently fire retardant, providing an added layer of safety in applications where fire resistance is crucial.

- Good Insulation: The cellular structure provides excellent thermal and sound insulation properties, contributing to energy efficiency and noise reduction.

- Easy to Fabricate: PVC Foam can be easily cut, drilled, screwed, glued, and thermoformed, allowing for versatile design options and efficient manufacturing.

- Durable and Long-Lasting: Resistant to rot, decay, and insect infestation, PVC Foam offers excellent durability and a long service life.

- Cost-Effective: Compared to some alternatives, PVC Foam offers a cost-effective solution, balancing performance and affordability.

Two Main Types of PVC Foam:

While generally referred to as PVC Foam, two primary types exist, each with distinct characteristics and applications:

- Free Foam PVC: Characterized by a harder, more compact surface skin and a softer, low-density core. This type is typically used for signage, display boards, and interior decoration.

- Celuka Foam PVC: Features a homogeneous structure throughout, with a hard, smooth surface and a consistent density. It offers higher strength and rigidity, making it suitable for structural applications like furniture, cabinetry, and construction components.

Applications Across Diverse Industries:

The unique properties of PVC Foam have led to its widespread use in diverse industries:

- Signage and Advertising: PVC Foam boards are a staple in the signage industry due to their lightweight nature, weather resistance, and ease of printing. They are used for indoor and outdoor signs, display boards, and point-of-sale materials.

- Construction: PVC Foam is utilized in construction for insulation panels, wall cladding, door and window profiles, and decorative moldings, contributing to energy efficiency and aesthetics.

- Furniture and Cabinetry: Its lightweight and moisture-resistant properties make PVC Foam a suitable material for furniture components, kitchen cabinets, and bathroom vanities.

- Transportation: In the transportation sector, PVC Foam is used for interior panels, headliners, and seating components in buses, trains, and recreational vehicles, contributing to weight reduction and improved aesthetics.

- Marine Industry: The water resistance of PVC Foam makes it ideal for marine applications such as boat interiors, decking, and flotation devices.

- Exhibitions and Events: PVC Foam’s ease of fabrication allows for creating lightweight and durable exhibition stands, displays, and props.

Looking to the Future:

As technology advances and sustainability concerns grow, the development of PVC Foam continues. Research focuses on improving its properties, exploring bio-based alternatives for PVC components, and enhancing recycling processes. The future of PVC Foam promises even more innovative applications and sustainable solutions for various industries.

Conclusion:

Polyvinyl Chloride Foam (PVC Foam) is a versatile and cost-effective material that offers a unique combination of properties. Its lightweight nature, water resistance, chemical resistance, and ease of fabrication have made it a popular choice in diverse industries. From signage and construction to furniture and transportation, PVC Foam continues to shape modern applications and contribute to innovation across various sectors. As research and development continue, the potential of PVC Foam remains vast, promising even more exciting applications in the future.

Reviews

There are no reviews yet.