Description

Polylactic Acid (PLA): The Bioplastic Revolution

In a world increasingly concerned with environmental sustainability, the search for eco-friendly alternatives to traditional plastics is paramount. Among the frontrunners in this revolution is Polylactic Acid, or PLA, a bioplastic derived from renewable resources. This article delves into the properties, applications, and environmental impact of PLA, exploring its potential to reshape the future of manufacturing and consumption.

What is PLA?

PLA is a thermoplastic polyester made from renewable resources like corn starch, sugarcane, or even cassava roots. Unlike conventional plastics that are derived from petroleum, PLA offers a bio-based alternative. The process involves fermenting these plant-based sources to produce lactic acid, which is then polymerized to create the PLA polymer.

Key Properties of PLA:

- Biodegradability: Under specific conditions, like those found in industrial composting facilities, PLA can decompose back into its natural elements. This reduces its long-term impact on the environment.

- Renewable Source: Sourcing PLA from renewable biomass minimizes reliance on fossil fuels, contributing to a more sustainable production cycle.

- Processability: PLA can be processed using various methods, including injection molding, extrusion, and thermoforming, making it versatile for different applications.

- Good Mechanical Properties: PLA exhibits decent strength, stiffness, and clarity, making it suitable for a range of applications.

- Low Toxicity: PLA is generally considered safe for food contact and medical applications.

Applications of PLA:

The versatility of PLA has led to its adoption across diverse industries:

- Packaging: PLA finds extensive use in food packaging, including containers, films, and disposable cutlery. Its biodegradability makes it a promising alternative to traditional plastic packaging.

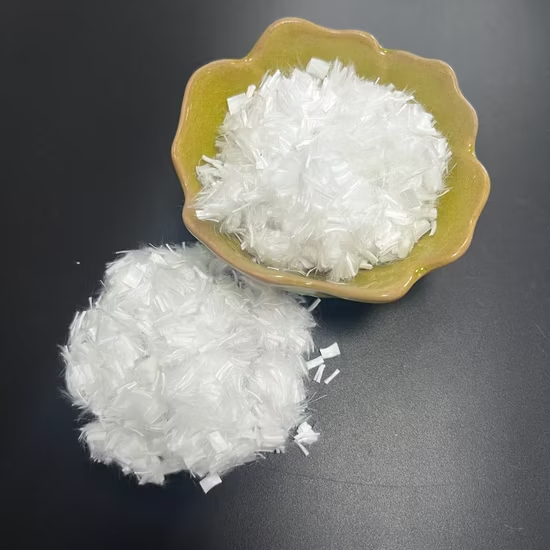

- Textiles: PLA fibers are used in clothing, upholstery, and non-woven fabrics.

- 3D Printing: PLA is a popular filament material for 3D printers due to its ease of use, low printing temperature, and biodegradable nature.

- Medical Applications: PLA’s biocompatibility makes it suitable for medical implants, sutures, and drug delivery systems.

- Agriculture: PLA films are used as mulch films in agriculture, biodegrading in the soil after their intended use.

Environmental Impact:

PLA offers significant environmental benefits compared to conventional plastics:

- Reduced Carbon Footprint: PLA production typically generates fewer greenhouse gas emissions than petroleum-based plastic production. This is because the carbon absorbed by the plants during growth offsets some of the emissions from manufacturing.

- Biodegradability: While PLA is not biodegradable in typical home composting conditions, it can break down in industrial composting facilities, reducing landfill waste.

- Renewable Resources: PLA is derived from renewable resources, decreasing dependence on finite fossil fuels.

Challenges and Limitations:

Despite its advantages, PLA faces some challenges:

- Biodegradability Requirements: PLA requires specific conditions (high temperature and humidity) to biodegrade effectively. These conditions are typically only found in industrial composting facilities, which are not widely available in all regions.

- Cost: PLA can be more expensive than traditional plastics, although this price gap is narrowing as production scales up.

- Mechanical Properties: While PLA has adequate strength for many applications, it may not be suitable for demanding applications requiring high impact resistance or flexibility.

- Sourcing Sustainability: Ensuring the sustainable sourcing of PLA feedstocks (like corn) is crucial to avoid negative impacts on land use, biodiversity, and food security.

Conclusion:

Polylactic Acid (PLA) represents a significant step forward in the quest for sustainable materials. Its bio-based origin, biodegradability (under specific conditions), and versatile applications make it a promising alternative to traditional plastics. While challenges remain in terms of cost, biodegradability requirements, and responsible sourcing, ongoing research and development are continually improving the properties and sustainability of PLA. As consumers and industries alike become more environmentally conscious, PLA is poised to play an increasingly important role in creating a more sustainable future. By embracing bioplastics like PLA, we can move closer to a circular economy that minimizes waste and protects our planet.

Reviews

There are no reviews yet.