Description

Maleic Anhydride: A Versatile Building Block of Industry

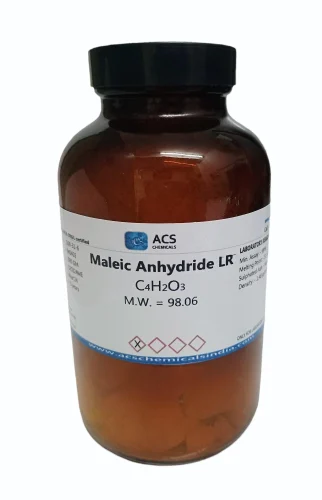

Maleic Anhydride (MAN), a seemingly unassuming organic compound, plays a surprisingly pivotal role in a vast array of industries. This colorless or white solid, characterized by a pungent odor, isn’t a final consumer product itself but rather a crucial intermediate used in the production of countless everyday items. From resins that give plastics their strength to coatings that protect surfaces, Maleic Anhydride’s versatility makes it a cornerstone of modern manufacturing.

What is Maleic Anhydride?

Chemically, Maleic Anhydride is an organic compound with the formula C4H2O3. It’s a cyclic anhydride of maleic acid, meaning it readily reacts with water to form maleic acid. This reactivity, thanks to its two carbonyl groups, is the key to its widespread applications.

Production Methods:

The primary methods for producing Maleic Anhydride involve the oxidation of benzene or n-butane.

- Benzene Oxidation: While historically dominant, this method is gradually being phased out due to environmental concerns related to benzene toxicity.

- n-Butane Oxidation: Currently, the most common production route involves the catalytic oxidation of n-butane. This process is considered more environmentally friendly and efficient than benzene oxidation.

Key Applications Across Industries:

Maleic Anhydride’s versatility stems from its ability to react with various compounds, making it a crucial building block in numerous industries. Here are some of its most prominent applications:

- Unsaturated Polyester Resins (UPR): This is by far the largest application of Maleic Anhydride, consuming over half of its global production. UPRs are used extensively in reinforced plastics for applications such as boat hulls, automotive parts, construction materials, and sanitary ware. The anhydride imparts strength, heat resistance, and chemical resistance to these resins.

- Alkyd Resins: Used in paints and coatings, alkyd resins benefit from the incorporation of Maleic Anhydride, which improves their drying time, hardness, and adhesion properties.

- Lubricant Additives: Maleic Anhydride derivates are used as detergent, dispersant, and viscosity modifier additives in lubricants, enhancing the performance and lifespan of engines and machinery.

- Fumaric and Malic Acids: Through hydration, Maleic Anhydride is converted into fumaric and malic acids. These are widely used in the food industry as acidulants, preservatives, and flavor enhancers.

- Tetrahydrofuran (THF): Maleic Anhydride can be converted to THF, a versatile solvent and intermediate used in the production of polymers, pharmaceuticals, and other chemicals.

- Copolymers and Other Polymers: Maleic Anhydride is incorporated into copolymers to modify their properties. For instance, it can improve the adhesion, dyeability, and water resistance of various polymer materials.

Global Market and Trends:

The global Maleic Anhydride market is significant and continuously evolving. The market is driven by the growing demand for UPR in construction and automotive industries, particularly in emerging economies. However, environmental regulations and the shift towards bio-based alternatives are influencing production methods and market dynamics. The increasing adoption of n-butane oxidation and the exploration of bio-derived Maleic Anhydride sources are key trends shaping the future of the industry.

Environmental and Safety Considerations:

While Maleic Anhydride is a valuable industrial chemical, it’s crucial to handle it with care. It’s an irritant to the skin, eyes, and respiratory system. Appropriate personal protective equipment and proper ventilation are essential during handling and processing. Furthermore, efforts are being made to develop more sustainable production methods and explore bio-based alternatives to reduce the environmental impact associated with its production.

Conclusion:

Maleic Anhydride, despite its seemingly simple structure, is a remarkably versatile chemical intermediate that underpins numerous industries. Its applications in resins, coatings, lubricants, and food additives underscore its importance in modern manufacturing. As industries continue to innovate and prioritize sustainability, the future of Maleic Anhydride will likely involve a shift towards more environmentally friendly production methods and the exploration of bio-based alternatives, ensuring its continued relevance as a vital building block for years to come.

Reviews

There are no reviews yet.