Description

Hafnium Tetrachloride (HfCl₄): A Versatile Precursor in Advanced Materials

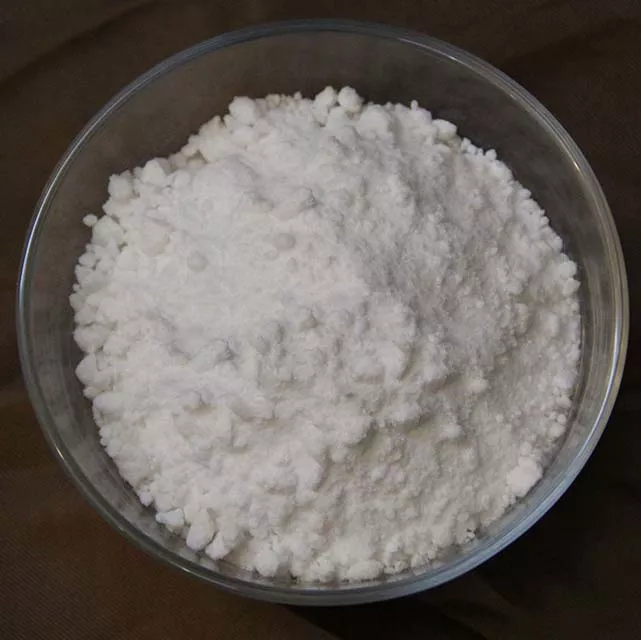

Hafnium tetrachloride (HfCl₄), a white crystalline inorganic compound, is far more than just another chemical formula. It stands as a crucial and highly reactive precursor, playing a pivotal role in the production of high-purity hafnium metal and, more significantly, in the cutting-edge field of microelectronics.

Chemical Nature and Properties

HfCl₄ is characterized by its high volatility, making it an excellent candidate for gas-phase deposition techniques. It readily sublimes, meaning it transitions directly from a solid to a gas without passing through a liquid phase, at relatively low temperatures (around 317°C at atmospheric pressure). This property is key to its utility in processes like Atomic Layer Deposition (ALD) and Chemical Vapor Deposition (CVD).

Chemically, hafnium tetrachloride is a powerful Lewis acid, capable of accepting electron pairs. It is highly reactive with moisture, undergoing rapid hydrolysis to form hafnium oxide (HfO₂) and hydrochloric acid (HCl):

HfCl₄(s) + 2H₂O(g) → HfO₂(s) + 4HCl(g)

This reaction highlights the need for careful handling under inert, dry conditions. Its strong reactivity and ability to form stable bonds with various ligands also make it a versatile compound in coordination chemistry.

Synthesis

The primary industrial method for producing hafnium tetrachloride involves the carbothermal chlorination of hafnium dioxide (HfO₂) in the presence of carbon at elevated temperatures:

HfO₂(s) + 2C(s) + 2Cl₂(g) → HfCl₄(g) + 2CO(g)

This process efficiently converts the oxide into the more volatile chloride, which can then be purified. Direct chlorination of hafnium metal can also yield HfCl₄, but it is less common for large-scale production.

Applications: Where HfCl₄ Shines

Hafnium tetrachloride’s unique properties translate into several critical applications across various industries:

- Hafnium Metal Production: HfCl₄ is a key intermediate in the purification and production of elemental hafnium. The chloride is reduced, typically with magnesium (similar to the Kroll process for titanium), to yield high-purity hafnium metal. This metal is highly valued for its excellent corrosion resistance, high melting point, and its distinct neutron absorption cross-section compared to zirconium, making it useful in nuclear control rods and other specialized alloys.

- High-k Dielectrics in Microelectronics: This is arguably the most significant modern application. As silicon dioxide (SiO₂) gate dielectrics in integrated circuits approached their physical limits, hafnium dioxide (HfO₂) emerged as a superior “high-k” material. HfCl₄ serves as a primary precursor for depositing ultra-thin, high-quality HfO₂ films using ALD and CVD techniques. These films are essential for enabling smaller, faster, and more power-efficient transistors in modern computer chips. The precise control offered by ALD using HfCl₄ allows for atomic-scale deposition, crucial for nanoscale device fabrication.

- Catalysis: Due to its strong Lewis acidity, HfCl₄ acts as an effective catalyst in various organic synthesis reactions, including Friedel-Crafts acylations, polymerizations, and chiral synthesis. It can promote reactions that require strong electrophilic activation.

- Precursor for Advanced Materials: Beyond HfO₂, HfCl₄ can be used as a starting material for synthesizing other hafnium-containing compounds, such as hafnium nitride (HfN) and hafnium carbide (HfC), which are known for their extreme hardness, high melting points, and chemical inertness, making them suitable for specialized coatings and ceramics.

Safety and Handling

Given its high reactivity with moisture, hafnium tetrachloride must be handled with extreme care under an inert atmosphere (e.g., nitrogen or argon) to prevent hydrolysis and the release of corrosive hydrogen chloride gas. It is corrosive to skin, eyes, and respiratory tracts, necessitating the use of appropriate personal protective equipment (PPE) such as gloves, eye protection, and a fume hood.

Conclusion

Hafnium tetrachloride, HfCl₄, stands as a testament to the power of inorganic chemistry in enabling technological advancements. From facilitating the production of high-performance hafnium metal to being an indispensable component in the fabrication of the most advanced microprocessors, its role as a versatile and reactive precursor is undeniable. As the demand for miniaturization and enhanced performance continues in electronics and other high-tech industries, HfCl₄ will undoubtedly remain a compound of significant interest and utility.

Reviews

There are no reviews yet.