Description

Zirconia-Supported Catalysts: A Versatile Platform for Enhanced Catalytic Performance

Catalysis is the bedrock of modern chemistry and industry, underpinning a vast array of processes ranging from fuel production to pharmaceuticals. The performance of a catalyst hinges on factors such as its activity, selectivity, and stability, all of which can be dramatically influenced by the support material it resides on. Among the diverse range of support materials, zirconia (zirconium dioxide, ZrO₂) has emerged as a particularly attractive option, leading to the development of a wide variety of high-performance zirconia-supported catalysts.

Why Zirconia? The Allure of a Multifaceted Support

Zirconia’s appeal as a catalyst support stems from its unique physicochemical properties. These include:

- High Thermal Stability: Zirconia exhibits exceptional thermal stability, maintaining its structural integrity at elevated temperatures. This is crucial for applications involving high-temperature reactions, preventing catalyst sintering and deactivation.

- Acidic and Basic Properties: Zirconia possesses both Lewis acid and Lewis base sites on its surface. This amphoteric nature allows it to participate actively in various catalytic reactions, including isomerization, dehydration, and hydrogenolysis. The strength and distribution of these sites can be tailored by controlling the synthesis method and post-treatment processes.

- Redox Activity: Depending on the operating conditions and the specific zirconia phase present (monoclinic, tetragonal, or cubic), zirconia can exhibit redox activity, facilitating reactions involving oxidation and reduction.

- High Surface Area: While the surface area of pristine zirconia can be relatively low, various synthesis techniques can be employed to create high-surface-area zirconia supports, ensuring excellent dispersion of the active catalytic species.

- Mechanical Strength: Zirconia possesses good mechanical strength, making it suitable for demanding industrial applications where durability is paramount.

- Tunable Morphology: The morphology of zirconia supports, including particle size, shape, and porosity, can be tailored through controlled synthesis techniques. This allows for optimizing mass transport and maximizing catalyst accessibility.

Applications of Zirconia-Supported Catalysts

The versatility of zirconia has led to its successful application in a broad spectrum of catalytic reactions:

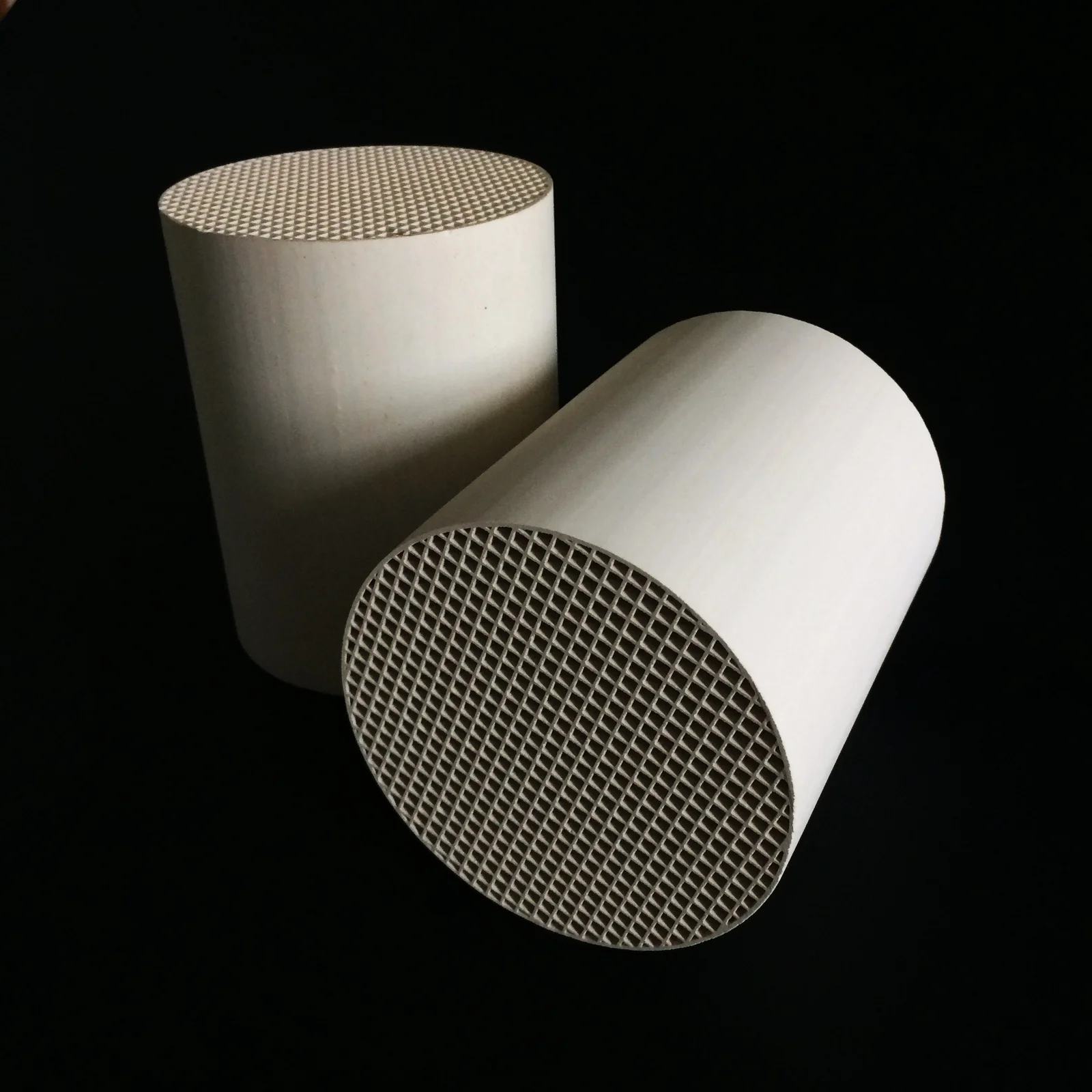

- Selective Catalytic Reduction (SCR): Zirconia-supported catalysts, particularly those incorporating metal oxides like vanadium oxide or copper oxide, are widely used in SCR processes for removing NOx emissions from exhaust gases. The zirconia provides a stable platform for the active metal and promotes the adsorption and activation of NOx molecules.

- Hydrocarbon Cracking and Isomerization: Zirconia exhibits intrinsic acidity, making it effective in catalyzing hydrocarbon cracking and isomerization reactions. Modified zirconia with sulfated or tungstated groups further enhances its acidity, leading to improved performance in these processes.

- Oxidation Reactions: Zirconia-supported noble metal catalysts (e.g., Pt/ZrO₂, Pd/ZrO₂) are employed in various oxidation reactions, including CO oxidation, VOC oxidation, and the selective oxidation of alcohols. The zirconia support promotes the dispersion of the noble metal and enhances its redox properties.

- CO2 Hydrogenation: Zirconia plays a crucial role in CO2 hydrogenation reactions, particularly in the synthesis of valuable chemicals like methanol and methane. Zirconia can act as a support for metal nanoparticles (e.g., Cu, Ni) and provide active sites for CO2 activation.

- Biomass Conversion: Zirconia-supported catalysts are also finding increasing applications in biomass conversion processes, such as the dehydration of sugars to produce platform chemicals.

Challenges and Future Directions

Despite its advantages, the development of zirconia-supported catalysts also faces certain challenges:

- Control of Zirconia Phase and Morphology: Achieving precise control over the zirconia phase and morphology during synthesis can be complex.

- Aggregation of Metal Nanoparticles: Maintaining the dispersion of metal nanoparticles on the zirconia support can be challenging, particularly at high temperatures.

- Cost Considerations: Zirconia can be more expensive than other common supports like alumina or silica.

Future research efforts are focused on:

- Developing novel synthesis methods to precisely control the zirconia phase, morphology, and surface properties.

- Exploring advanced techniques like atomic layer deposition (ALD) to achieve uniform and highly dispersed metal loading on zirconia surfaces.

- Rational design of bimetallic and trimetallic catalysts supported on zirconia to further enhance catalytic activity and selectivity.

- Investigating the role of zirconia defects and oxygen vacancies in catalytic reactions.

- Developing cost-effective methods for producing high-quality zirconia supports.

Conclusion:

Zirconia-supported catalysts represent a versatile platform for achieving enhanced catalytic performance in a wide range of applications. Their unique physicochemical properties, including high thermal stability, tunable acidity and basicity, and redox activity, make them a compelling choice for various catalytic processes. Continued research and development efforts are expected to further unlock the potential of zirconia-supported catalysts and expand their applications in diverse fields, contributing to a more sustainable and efficient future.

Reviews

There are no reviews yet.