Description

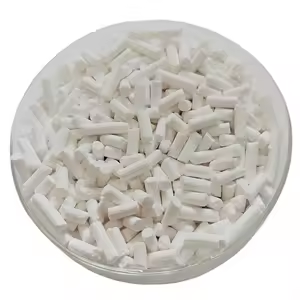

Zeolite Catalysts: Tiny Structures, Huge Impact on Chemistry

Zeolites, a class of crystalline aluminosilicates, are making waves in the world of catalysis. Their unique structural properties and versatility have made them indispensable in a wide range of industrial applications, from petroleum refining to fine chemical synthesis. This article delves into the fascinating world of zeolite catalysts, exploring their structure, properties, and the profound impact they have on modern chemistry.

What are Zeolites?

The name “zeolite” comes from the Greek words “zeo” (to boil) and “lithos” (stone), a nod to their ability to release water when heated. These materials possess a distinctive three-dimensional framework constructed from interconnected tetrahedra of silicon and aluminum oxides. This framework creates a network of interconnected channels and cavities of uniform size, ranging from a few angstroms to nanometers.

The presence of aluminum in the framework creates a negative charge, which is balanced by positively charged cations like sodium, potassium, or calcium. These cations, along with the size and shape of the channels and cavities, are key determinants of a zeolite’s properties and catalytic activity.

Key Properties that Make Zeolites Excellent Catalysts:

- Shape Selectivity: This is arguably the most defining characteristic of zeolite catalysts. The uniform pore size and shape allow only specific molecules to enter the structure, react, and exit. This selectivity can be based on the size, shape, or polarity of the reactants and products, leading to highly specific reactions and minimizing unwanted byproducts.

- High Surface Area: Zeolites possess an exceptionally high internal surface area, providing a large number of active sites for catalytic reactions to occur. This high surface area translates to increased reaction rates and efficiency.

- Thermal Stability: Zeolites are remarkably stable at high temperatures, making them suitable for use in demanding industrial processes.

- Tunable Acidity: The presence of aluminum in the framework generates Brønsted acid sites, which can catalyze a wide range of acid-catalyzed reactions. The strength and type of acidity can be tailored by modifying the zeolite composition and structure.

- Easy Recovery and Reuse: Zeolites are solid materials, making them easily separable from reaction mixtures and allowing for repeated use, contributing to sustainable and cost-effective processes.

Applications in Catalysis:

The unique properties of zeolite catalysts have led to their widespread adoption in diverse areas:

- Petroleum Refining: Zeolites are critical in cracking large hydrocarbon molecules into smaller, more valuable components like gasoline and diesel. They are also used in isomerization, alkylation, and other refinery processes.

- Petrochemical Industry: Zeolites catalyze a range of reactions, including the production of olefins, aromatics, and other important building blocks for plastics, synthetic fibers, and other materials.

- Fine Chemical Synthesis: Zeolites are finding increasing application in the synthesis of pharmaceuticals, agrochemicals, and other specialty chemicals. Their shape selectivity allows for the production of specific isomers and enantiomers, which is crucial in the pharmaceutical industry.

- Environmental Applications: Zeolites are used in catalytic converters to reduce harmful emissions from vehicles. They can also be used to remove pollutants from water and air.

Beyond Traditional Zeolites: Metal-Organic Frameworks (MOFs)

While zeolites have been dominant, research is expanding to include other porous materials like Metal-Organic Frameworks (MOFs). MOFs offer even greater flexibility in terms of pore size, functionality, and metal incorporation, paving the way for new and improved catalysts.

Future Directions:

The field of zeolite catalysis continues to evolve with ongoing research focused on:

- Developing new zeolite structures with tailored properties: Researchers are exploring novel synthesis methods and modifications to create zeolites with specific pore sizes, shapes, and acidity.

- Incorporating metals and other active components into zeolites: This can enhance catalytic activity and selectivity for specific reactions.

- Understanding the reaction mechanisms at the atomic level: This knowledge helps in the rational design of more effective catalysts.

- Developing sustainable and environmentally friendly catalytic processes: Zeolites are playing a key role in reducing waste, increasing efficiency, and minimizing the environmental impact of chemical processes.

Conclusion:

Zeolite catalysts are a testament to the power of materials science in solving complex chemical problems. Their unique combination of shape selectivity, high surface area, and tunable acidity has revolutionized various industries and continues to drive innovation in catalysis. As research progresses and new materials emerge, zeolites and related porous materials will undoubtedly play an even more significant role in shaping the future of chemistry, contributing to a cleaner, more sustainable, and more efficient world.

Reviews

There are no reviews yet.