Description

The Unsung Hero of Chemistry: Tungsten Catalysts and Their Diverse Applications

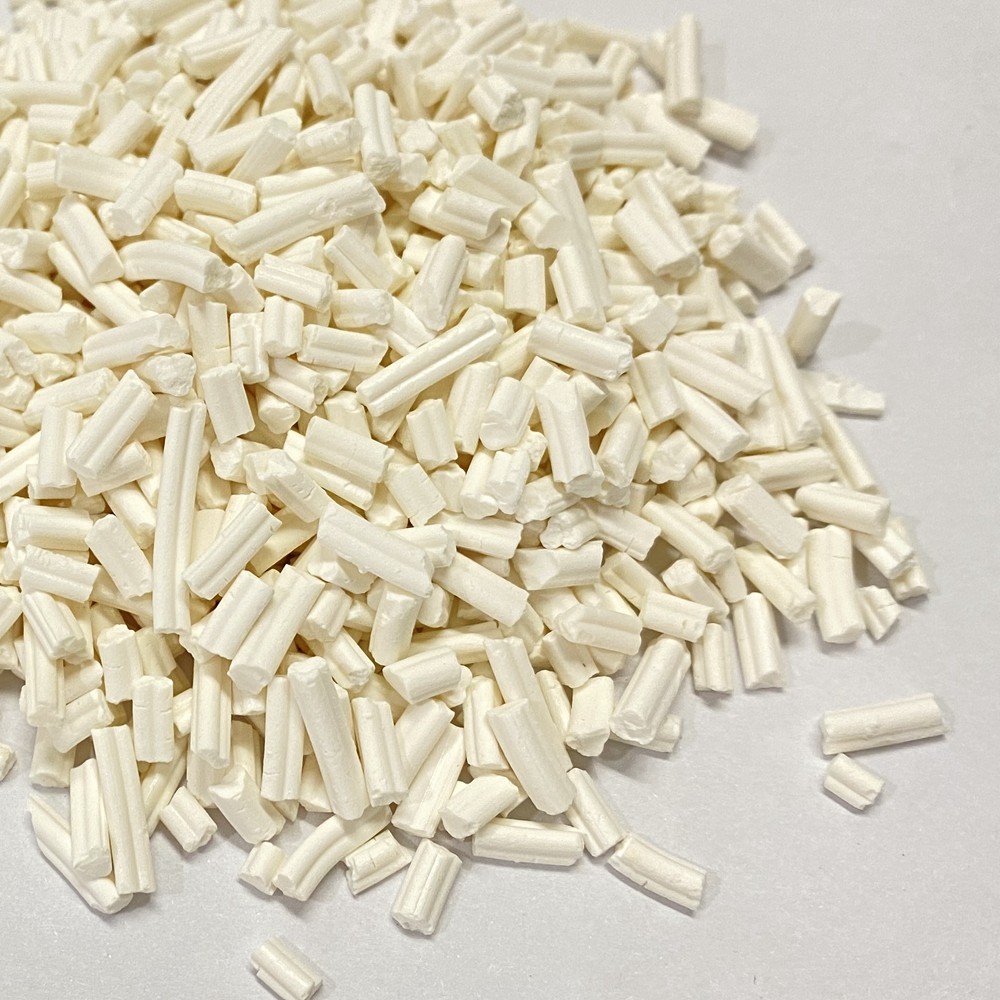

Tungsten, a heavy, silvery-white metal known for its high melting point and strength, might be more familiar in the context of light bulb filaments. However, this fascinating element plays a crucial, often overlooked, role in the world of chemistry as a powerful and versatile catalyst. Tungsten catalysts are quietly driving a vast array of chemical reactions, contributing to the production of everything from plastics to pharmaceuticals and playing a vital role in energy production and environmental remediation.

Why Tungsten? The Allure of Activity and Stability

The effectiveness of tungsten as a catalyst stems from its unique electronic structure and chemical properties. Its ability to exist in multiple oxidation states allows it to facilitate a variety of bond-breaking and bond-forming processes. Furthermore, tungsten compounds often exhibit exceptional thermal and chemical stability, making them robust and long-lasting catalysts suitable for harsh reaction conditions.

A Diverse Portfolio of Applications

Tungsten catalysts find applications across a broad spectrum of chemical fields:

- Alkene Metathesis: One of the most significant applications is in alkene metathesis, a revolutionary reaction that allows for the shuffling and rearrangement of carbon-carbon double bonds. Tungsten-based catalysts, particularly those containing carbene ligands, have been instrumental in the development of this powerful synthetic tool, which is used to create complex molecules, polymers, and pharmaceuticals.

- Olefin Polymerization: Tungsten catalysts are also employed in the polymerization of olefins, the building blocks of many common plastics. These catalysts can produce polymers with specific architectures and properties, tailoring the final product for specific applications.

- Oxidation Reactions: Tungsten oxides and peroxotungstates are effective catalysts for various oxidation reactions, playing a crucial role in the selective oxidation of alcohols, hydrocarbons, and other organic substrates. These reactions are essential in the synthesis of various valuable chemicals and intermediates.

- Environmental Remediation: In the fight against pollution, tungsten catalysts are finding increasing use in the degradation of pollutants in wastewater and air. For instance, they can be used to catalyze the decomposition of harmful organic compounds and nitrogen oxides, helping to clean up contaminated environments.

- Hydrogenation and Dehydrogenation: Tungsten sulfide, a common component in hydrodesulfurization catalysts, plays a critical role in the petroleum industry. These catalysts remove sulfur compounds from crude oil, preventing the formation of acid rain and improving the quality of fuels.

- Ammonia Synthesis: While the Haber-Bosch process predominantly uses iron catalysts for ammonia synthesis, tungsten has been explored as a potential alternative or co-catalyst, particularly under specific reaction conditions.

Advantages and Challenges

While tungsten catalysts offer numerous advantages, including high activity and stability, there are also challenges to consider:

- Cost: Compared to some other transition metals, tungsten can be relatively expensive. This cost factor can limit its widespread use in certain applications.

- Toxicity: Some tungsten compounds can exhibit toxicity, requiring careful handling and disposal.

- Sensitivity to Oxygen and Water: Some types of tungsten catalysts can be sensitive to oxygen and water, requiring specialized handling and storage conditions.

The Future of Tungsten Catalysis

The field of tungsten catalysis is continuously evolving, with ongoing research focused on:

- Developing more efficient and selective catalysts: Researchers are striving to design catalysts with enhanced activity and selectivity, reducing unwanted side reactions and improving overall efficiency.

- Exploring new applications: The versatility of tungsten catalysts makes them promising candidates for new applications in fields such as biomass conversion and energy storage.

- Developing heterogeneous catalysts: Heterogeneous catalysts, which are solid catalysts that can be easily separated from the reaction mixture, are particularly desirable due to their recyclability and ease of handling.

In conclusion, tungsten catalysts, though often unseen, are indispensable tools in the world of chemistry. Their unique properties and diverse applications contribute significantly to the production of countless products and technologies that impact our daily lives. As research continues to unlock the full potential of these remarkable materials, we can expect to see even more innovative applications of tungsten catalysts in the future.

Reviews

There are no reviews yet.