Description

Sodium Silicate: The Versatile Compound Shaping Industries

Sodium silicate, often referred to as water glass, is a remarkable inorganic chemical compound with a surprisingly wide range of applications. From strengthening concrete to serving as a binder in detergents, this versatile substance plays a crucial role in various industries. But what exactly is sodium silicate, and what makes it so useful?

Understanding Sodium Silicate

Sodium silicate isn’t a single compound but rather a family of compounds with the general formula Na₂SiOₓ·nH₂O. They are essentially glassy materials when anhydrous and can be dissolved in water to form a viscous, alkaline solution. The ratio of silica (SiO₂) to sodium oxide (Na₂O), represented by the ‘x’ in the formula, determines its characteristics and applications. A higher ratio generally leads to a harder, more resistant material.

Production and Properties

Sodium silicate is primarily produced through the reaction of silica sand (SiO₂) with sodium carbonate (Na₂CO₃) or sodium hydroxide (NaOH) at high temperatures. This process results in molten sodium silicate, which can then be cooled and processed into various forms, including:

- Solid forms: Glassy lumps, powders, and granules.

- Liquid forms: Solutions of varying viscosities and concentrations.

Key properties of sodium silicate include:

- Alkalinity: It is a strong alkaline solution with a high pH.

- Binding capabilities: It acts as an excellent adhesive and binder.

- Stabilizing properties: It can stabilize soils and other materials.

- Sealing properties: It can effectively seal pores and cracks.

- Fire resistance: It is non-combustible and can improve the fire resistance of materials.

A Myriad of Applications

The unique properties of sodium silicate make it a valuable ingredient in a multitude of applications:

- Construction: Used as a concrete hardener, sealant, and to improve the durability and water resistance of cement-based materials. It also stabilizes soil during construction projects.

- Detergents and cleaning products: Serves as a builder and corrosion inhibitor in detergents and cleaning formulations. It enhances the cleaning power, prevents redeposition of dirt, and protects metal surfaces from corrosion.

- Pulp and paper industry: Used as a bleaching agent stabilizer and to improve paper strength and brightness.

- Textile industry: Employed as a peroxide stabilizer in bleaching processes and as a mordant in dyeing.

- Ceramics: Utilized as a deflocculant in ceramic slip production, which helps to maintain the suspension of clay particles.

- Adhesives: Used as a binder in various industrial adhesives, especially for paper and cardboard.

- Water treatment: Acts as a flocculant to remove impurities and suspended solids from water.

- Foundry: Used as a binder in sand casting to create molds and cores.

- Welding: Used as a binder and flux in welding electrodes.

- Refractories: It helps to bind refractory materials together, creating highly heat-resistant products.

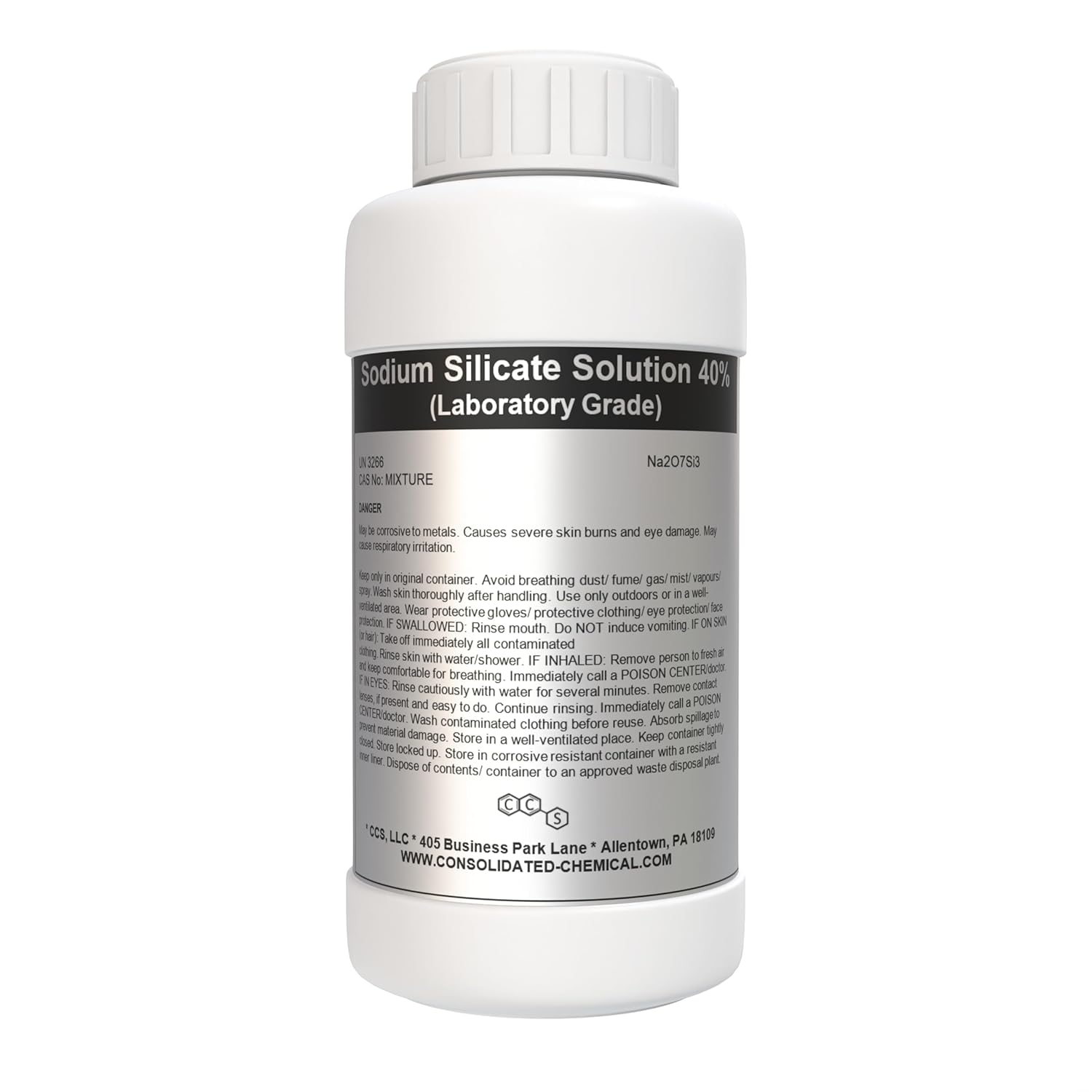

Considerations and Safety

While sodium silicate offers numerous benefits, it’s important to handle it with care. Being a strong alkaline solution, it can cause skin and eye irritation upon contact. Appropriate personal protective equipment, such as gloves and eye protection, should be worn when handling it.

The Future of Sodium Silicate

With increasing focus on sustainable and eco-friendly solutions, research is continually exploring new applications of sodium silicate. Its potential in areas like green concrete, sustainable building materials, and improved soil stabilization offers exciting possibilities for the future.

In conclusion, sodium silicate is a truly versatile compound with a wide array of applications that touch our lives in many ways. Its unique properties and relatively low cost make it an indispensable material across numerous industries, solidifying its position as a valuable component in modern manufacturing and construction. As research continues, we can expect even more innovative uses for this remarkable substance in the years to come.

Reviews

There are no reviews yet.