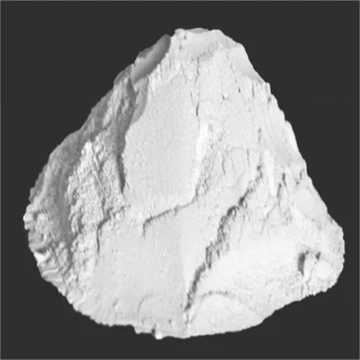

Description

Silica Pigments: Unsung Heroes of Modern Color

While pigments like titanium dioxide and iron oxides often steal the spotlight, silica pigments stand as unsung heroes in the world of color and coatings. These versatile materials, based on silicon dioxide (SiO2), offer a unique blend of properties that make them invaluable in a wide range of applications, from paints and plastics to cosmetics and even food.

What are Silica Pigments?

Unlike traditional pigments that impart color directly through absorption and reflection of light, silica pigments are generally colorless and work through different mechanisms. They are essentially finely divided particles of silica, available in various forms like precipitated silica, fumed silica, and silica gels. Their primary function isn’t to provide hue, but rather to modify and enhance other properties of the materials in which they are incorporated.

The Power of Silica: Beyond Color

Their contribution lies in providing a multitude of benefits, including:

- Matting Agents: Silica pigments are excellent matting agents, meaning they reduce gloss and produce a flat, matte finish. This is achieved by scattering light on the surface due to the irregular shape and particle size of the silica. This is highly desirable in applications like architectural paints, automotive coatings, and paper coatings.

- Dispersing Agents and Rheology Modifiers: They can improve the dispersion of other pigments, preventing agglomeration and ensuring uniform color distribution. Silica pigments can also control the viscosity and flow properties (rheology) of coatings, making them easier to apply and preventing sagging or settling.

- Anti-Blocking Agents: In plastic films and coatings, silica pigments prevent sticking or “blocking” by creating microscopic surface roughness. This is crucial in packaging applications where layers of film need to be easily separated.

- Texture and Hiding Power Enhancement: The addition of silica pigments can influence the texture of a coating, providing a rougher or smoother feel. They can also contribute to the overall hiding power (opacity) of a paint or coating by scattering light and preventing the substrate from being seen through the coating.

- Anti-Corrosion Properties: Certain types of silica pigments can improve the corrosion resistance of coatings by forming a barrier that inhibits the penetration of moisture and corrosive agents.

- Carriers and Stabilizers: Silica pigments can act as carriers for other active ingredients, such as UV absorbers or antimicrobial agents, in various applications. They can also help stabilize emulsions and prevent settling.

Applications Spanning Industries:

The versatility of silica pigments makes them indispensable across diverse industries:

- Paints and Coatings: They are widely used in architectural paints, automotive coatings, industrial coatings, and wood finishes to control gloss, improve durability, and enhance other performance characteristics.

- Plastics: Silica pigments are employed in plastic films, sheets, and molded parts to prevent blocking, improve processability, and enhance surface properties.

- Inks: They can improve the printability and rub resistance of inks, ensuring sharp and long-lasting images.

- Cosmetics: In cosmetic formulations, silica pigments contribute to a smooth, matte finish in makeup products like powders, foundations, and eyeshadows. They can also absorb excess oil and improve the feel of the product on the skin.

- Food Industry: Certain types of silica are used as anti-caking agents in powdered foods, preventing them from clumping and ensuring free flow.

- Pharmaceuticals: They are used as carriers for drug delivery and as glidants in tablet formulations.

The Future of Silica Pigments:

Research and development are constantly pushing the boundaries of silica pigment technology. Innovations focus on:

- Surface modification: Tailoring the surface chemistry of silica pigments to optimize their interaction with specific materials and improve their performance.

- Particle size control: Precisely controlling the particle size distribution to achieve desired properties, such as gloss control and dispersion stability.

- Hybrid materials: Combining silica with other materials, like polymers or metal oxides, to create novel pigments with enhanced functionality.

In conclusion, silica pigments, though often invisible to the naked eye, play a critical role in enhancing the performance, aesthetics, and functionality of a wide range of products. Their unique properties and versatility ensure they will continue to be valuable components in the future of color, coatings, and beyond.

Reviews

There are no reviews yet.