Description

The Unsung Hero of Chemistry: Silica Gel as a Catalyst

Silica gel, a ubiquitous material often found in small packets protecting our electronics and shoes from moisture, is more than just a desiccant. This seemingly simple substance is also a versatile and increasingly important catalyst in a wide range of chemical reactions. While its catalytic properties might be less known than its drying capabilities, silica gel is proving to be a valuable and cost-effective tool in various industries, from petrochemicals to pharmaceuticals.

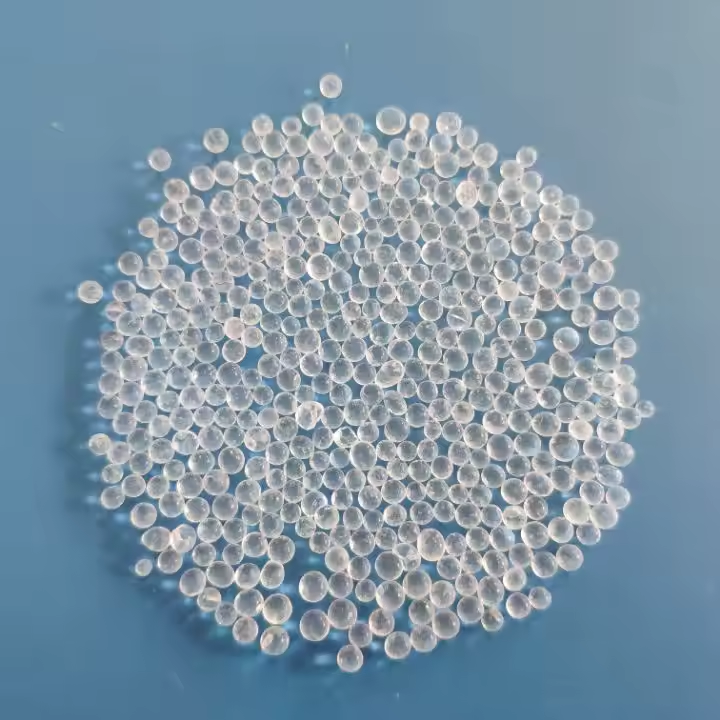

Beyond Moisture Control: Understanding Silica Gel’s Structure

To understand silica gel’s catalytic prowess, it’s essential to delve into its unique structure. It’s a form of silicon dioxide (SiO2) created through the sol-gel process, resulting in a highly porous and amorphous solid. This high surface area is the key to its effectiveness. The surface is rich in silanol (Si-OH) groups, which are weakly acidic in nature. These silanol groups act as active sites, facilitating chemical reactions by providing a platform for reactants to adsorb, interact, and ultimately transform into products.

Silica Gel: A Versatile Catalyst

The catalytic potential of silica gel stems from its ability to act as:

- Solid Acid Catalyst: The acidic silanol groups can catalyze reactions that typically require traditional acids, such as:

- Esterification: The formation of esters from carboxylic acids and alcohols.

- Etherification: The formation of ethers from alcohols.

- Alkylation: The addition of alkyl groups to aromatic rings.

- Polymerization: The creation of long-chain molecules from smaller monomers.

- Support for Other Catalysts: Silica gel’s high surface area makes it an excellent support material for immobilizing other, more active, catalysts. By anchoring metal complexes or enzymes onto the silica gel surface, scientists can create highly efficient and reusable catalysts. This approach offers several advantages, including:

- Enhanced catalytic activity: The high dispersion of the active catalyst on the silica gel surface maximizes its exposure to reactants.

- Improved catalyst stability: The support can protect the active catalyst from deactivation or degradation.

- Easy recovery and reuse: The solid silica gel support allows for simple separation of the catalyst from the reaction mixture, enabling its reuse in subsequent reactions.

Applications of Silica Gel Catalysts

The versatile nature of silica gel as a catalyst has led to its application in a wide range of industries, including:

- Petrochemical Industry: Used in cracking and isomerization reactions to produce fuels and other valuable chemicals.

- Pharmaceutical Industry: Employed in the synthesis of various drug intermediates and active pharmaceutical ingredients (APIs).

- Fine Chemical Industry: Utilized in the production of specialty chemicals, flavors, and fragrances.

- Environmental Remediation: Incorporated in catalytic oxidation processes to remove pollutants from air and water.

Advantages of Using Silica Gel as a Catalyst

Compared to traditional catalysts, silica gel offers several noteworthy advantages:

- Cost-effectiveness: Silica gel is a relatively inexpensive and readily available material.

- Environmentally friendly: It is non-toxic and does not pose significant environmental hazards.

- High thermal stability: Silica gel can withstand high temperatures without degrading, making it suitable for high-temperature reactions.

- Tunable properties: Its pore size, surface area, and acidity can be tailored by adjusting the synthesis conditions, allowing for the design of catalysts with specific properties.

Future Directions

Research into silica gel catalysts is constantly evolving, with scientists exploring new ways to enhance its catalytic activity and broaden its applications. Current research focuses on:

- Modifying the silica gel surface with functional groups to create catalysts with enhanced selectivity and activity.

- Developing novel methods for immobilizing metal nanoparticles on silica gel supports for improved catalytic performance.

- Exploring the use of mesoporous silica materials with larger pores and higher surface areas for catalysis of bulky molecules.

Conclusion

Silica gel, often overlooked as a simple desiccant, is a surprisingly versatile and valuable catalyst. Its unique structure, high surface area, and ability to act as both a solid acid catalyst and a support material make it an attractive option for a wide range of chemical reactions. As research continues to unlock its full potential, silica gel is poised to play an increasingly important role in the future of catalysis, contributing to more sustainable and efficient chemical processes. The next time you see a packet of silica gel, remember that it represents more than just dryness – it represents a world of chemical possibilities.

Reviews

There are no reviews yet.