Description

Understanding Screen Printing Mesh: The Foundation of a Great Print

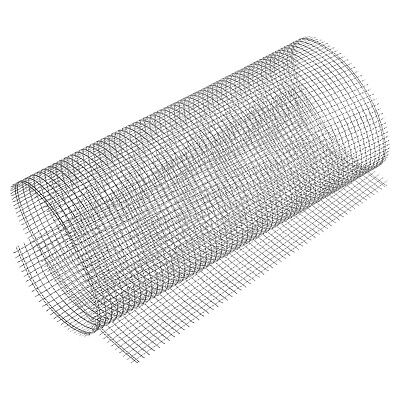

Screen printing, a versatile and enduring printing technique, relies on a seemingly simple but incredibly crucial component: the mesh. This finely woven fabric stretched tautly over a frame forms the stencil through which ink is forced onto a substrate, creating vibrant and durable prints on everything from t-shirts to posters to circuit boards. But screen printing mesh isn’t just “fabric”; it’s a carefully engineered material with a variety of factors influencing the quality and suitability for a particular printing job.

Understanding the nuances of screen printing mesh is essential for achieving professional-looking results and controlling the intricacies of your prints. Let’s dive into the key aspects of this foundational element:

Material Matters: Polyester vs. Nylon and Beyond

While different materials have been used historically, today, the most common mesh materials are:

- Polyester: The workhorse of the screen printing industry. Polyester offers excellent dimensional stability, meaning it’s less prone to stretching or distorting during printing. It’s also highly resistant to chemicals and abrasion, making it ideal for a wide range of inks and applications. Polyester is generally the preferred choice for most screen printing projects due to its versatility and durability.

- Nylon: Known for its elasticity and ability to conform to irregular surfaces. This makes nylon mesh suitable for printing on curved or textured objects. However, nylon is more susceptible to stretching and ink solvents than polyester, requiring careful handling and specific ink compatibility.

- Stainless Steel: Used in specialized applications requiring extreme precision and durability, such as microprinting and the printing of electronic components. Stainless steel mesh is exceptionally stable and resistant to harsh chemicals and high temperatures.

Mesh Count: Defining the Detail

The mesh count refers to the number of threads per inch (TPI) or centimeter (TPC) in the mesh. This number directly influences the resolution and ink deposit of your print.

- Lower Mesh Count (e.g., 40-86 TPI): Larger openings allow for thicker ink deposits, ideal for printing bold designs, filling large areas, and printing with specialty inks like glitter or puff ink. They are also often used for printing on rougher materials like textiles.

- Medium Mesh Count (e.g., 110-200 TPI): A versatile range suitable for general-purpose printing, including text and graphics with moderate detail.

- Higher Mesh Count (e.g., 230-355+ TPI): Provides finer detail and control over ink deposit, making it perfect for halftones, intricate designs, and thinner inks. These meshes are also suitable for process color printing, where precise ink layering is crucial.

Thread Diameter: Strength and Ink Flow

The thread diameter, measured in micrometers, affects the mesh’s strength and ability to hold detail. Thicker threads generally provide a stronger mesh, while thinner threads allow for finer detail and better ink flow. Choosing the right thread diameter is a balancing act between durability and resolution.

Mesh Color: Impact on Exposure

While not as critical as mesh count, the color of the mesh can influence the exposure process.

- White Mesh: Offers the sharpest image resolution but can cause light scattering during exposure, potentially leading to undercutting.

- Yellow Mesh: Absorbs UV light, minimizing light scattering and resulting in sharper edges, especially for fine details and halftones. Yellow mesh is a popular choice for exposing complex designs.

Choosing the Right Mesh for Your Project

Selecting the appropriate screen printing mesh is crucial for achieving the desired results. Consider these factors when making your choice:

- Design Complexity: Finer details require higher mesh counts.

- Ink Type: Some inks require lower mesh counts for proper deposition.

- Substrate: The material you’re printing on will influence the required mesh count and material.

- Desired Ink Deposit: Thicker inks and bold designs benefit from lower mesh counts.

Maintaining Your Mesh: Extending its Lifespan

Proper cleaning and maintenance are essential for prolonging the life of your screen printing mesh. After each print run, thoroughly clean the mesh to remove all traces of ink and emulsion. Use appropriate cleaning solvents and techniques to avoid damaging the mesh. Regular inspection for wear and tear is also recommended.

Conclusion:

Screen printing mesh might seem like a simple fabric, but its properties directly impact the quality, detail, and durability of your prints. Understanding the different types of mesh, their characteristics, and how they interact with inks and substrates is crucial for any screen printer. By carefully considering your design requirements and choosing the right mesh, you can unlock the full potential of screen printing and achieve stunning results. So, take the time to learn the nuances of this critical component, and you’ll be well on your way to creating professional-quality prints that stand out.

Reviews

There are no reviews yet.