Description

Refined Wire Mesh: Beyond the Basics – A Versatile Material for Modern Applications

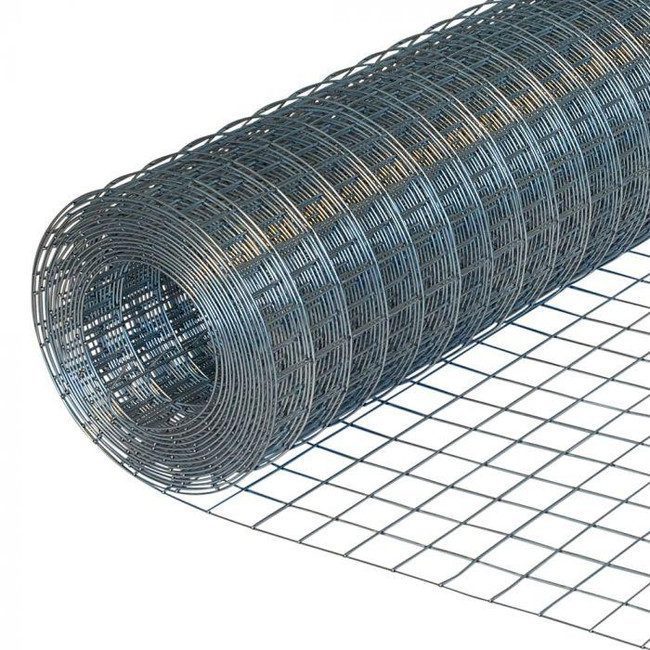

Wire mesh, in its simplest form, is a woven or welded network of metal wires. But the world of wire mesh has evolved far beyond basic fences and screens. Refined wire mesh, characterized by its precise construction, diverse materials, and specialized treatments, is finding its place in a wide range of sophisticated applications, offering a unique combination of strength, permeability, and adaptability.

What Makes Wire Mesh “Refined?”

The term “refined” in the context of wire mesh encompasses several key aspects:

- Material Variety: While traditional wire mesh might be made from steel, refined wire mesh utilizes a significantly broader palette of materials, including stainless steel (various grades), aluminum, copper, brass, nickel alloys, and even specialty metals like titanium. This material selection allows for specific properties such as corrosion resistance, high-temperature tolerance, or electrical conductivity to be tailored to the application.

- Precision Manufacturing: The weaving or welding process is carefully controlled to achieve consistent mesh size, wire diameter, and overall integrity. This precision is crucial for applications requiring accurate filtration, separation, or electromagnetic shielding.

- Specific Weave Patterns: Beyond the standard square weave, refined wire mesh utilizes various weave patterns like twill weave, plain Dutch weave, and reverse Dutch weave. Each pattern offers unique characteristics in terms of strength, filtration efficiency, and surface smoothness.

- Surface Treatments and Coatings: To further enhance performance, refined wire mesh undergoes various surface treatments, including polishing, electroplating, powder coating, and passivation. These treatments can improve corrosion resistance, aesthetics, and biocompatibility.

- Customization and Fabrication: Refined wire mesh is often tailored to specific customer needs through cutting, forming, welding, and other fabrication processes. This allows for integration into complex systems and devices.

Applications Across Industries

The unique attributes of refined wire mesh have made it indispensable across numerous industries:

- Filtration and Separation: From critical oil and gas filtration to pharmaceutical processing, refined wire mesh is used to separate solids, liquids, and gases with high precision. Its controlled pore size allows for specific particle retention, ensuring product quality and process efficiency.

- Aerospace and Automotive: In these demanding industries, refined wire mesh is employed in applications like air intake screens, EMI/RFI shielding, fuel filters, and catalyst supports. Its lightweight nature, high strength, and corrosion resistance are highly valued.

- Electronics: Refined wire mesh plays a crucial role in electronic components, acting as shielding against electromagnetic interference (EMI) and radio frequency interference (RFI). It’s also used in conductive gaskets and battery components.

- Medical: Biocompatible grades of stainless steel and titanium wire mesh are used in implantable devices, surgical meshes, and filtration systems. Its open structure promotes tissue integration and fluid flow.

- Food and Beverage: Sanitary grades of wire mesh are used in food processing equipment, filtration systems, and drying conveyors, ensuring hygiene and preventing contamination.

- Architecture and Design: Beyond its functional applications, refined wire mesh is increasingly used in architectural features, decorative panels, and lighting fixtures. Its aesthetic appeal and versatility allow for creative design solutions.

The Future of Refined Wire Mesh

As technology advances, the demand for highly specialized and refined wire mesh solutions will continue to grow. Research and development efforts are focused on:

- New Materials: Exploring the use of advanced materials like graphene and shape-memory alloys to create wire mesh with unprecedented properties.

- Nanomesh Fabrics: Developing wire mesh with nanoscale pore sizes for ultra-filtration and separation applications.

- Smart Wire Mesh: Integrating sensors and actuators into wire mesh structures to create intelligent systems for monitoring and control.

Conclusion

Refined wire mesh is far more than just a simple woven material. It’s a highly engineered product that combines material science, precision manufacturing, and innovative design to solve complex challenges across a wide range of industries. As technology continues to evolve, refined wire mesh will undoubtedly play an increasingly important role in shaping the future. By understanding its capabilities and potential, engineers, designers, and manufacturers can unlock new possibilities and create innovative solutions that were previously unimaginable.

Reviews

There are no reviews yet.