Description

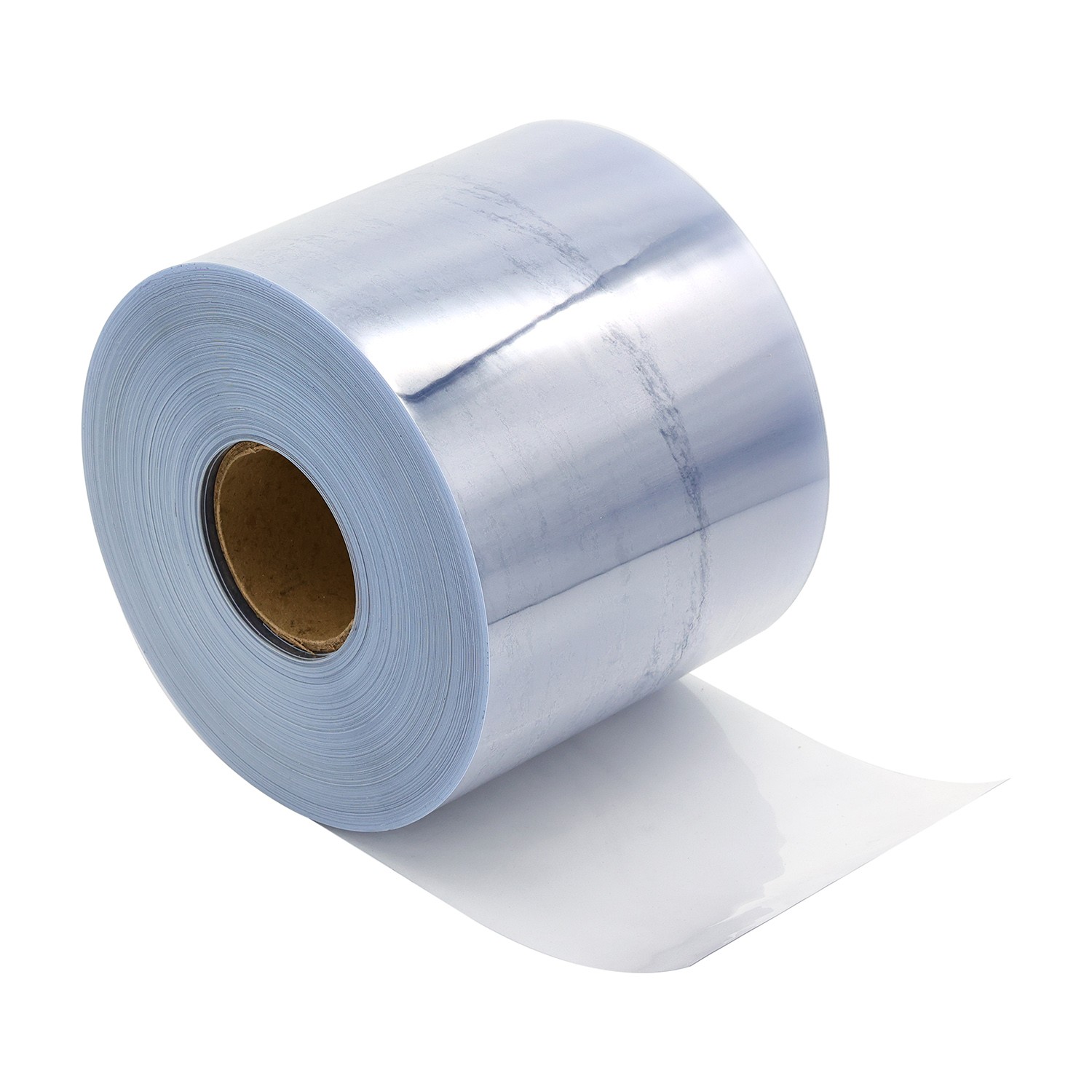

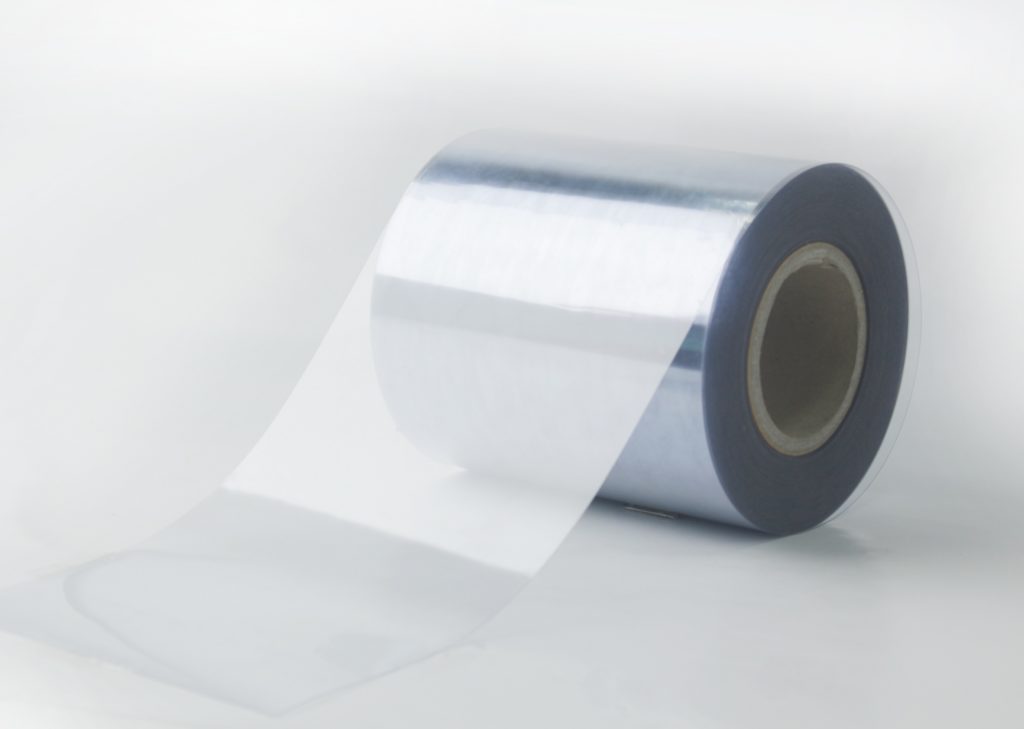

Polyvinylidene chloride, commonly referred to as PVDC, is a versatile and widely used synthetic polymer. It is a thermoplastic resin that is derived from the monomer vinylidene chloride (1,1-dichloroethylene). PVDC is known for its excellent barrier properties, chemical resistance, and durability, making it a popular choice for a variety of applications in industries such as food packaging, medical devices, and electronics.

Properties of PVDC

- Barrier properties: PVDC has an exceptional ability to resist the permeation of gases, moisture, and aromas. This property makes it an ideal material for food packaging applications, as it helps to preserve the freshness and shelf-life of the products.

- Chemical resistance: PVDC is highly resistant to a wide range of chemicals, including acids, alkalis, and solvents. This characteristic makes it suitable for applications where chemical resistance is crucial, such as in the production of medical devices and electronic components.

- Durability: PVDC is a strong and tough material that can withstand mechanical stress and maintain its integrity under various environmental conditions.

- Transparency: PVDC has excellent optical properties, which makes it suitable for applications that require high clarity and transparency.

- Processability: PVDC can be easily processed using various techniques, such as extrusion, injection molding, and blow molding, allowing for the production of a wide range of products with different shapes and sizes.

Applications of PVDC

- Food packaging: PVDC is widely used in the food packaging industry due to its excellent barrier properties. It is commonly used in the production of films, pouches, and trays for packaging various food products, such as meat, cheese, and snacks.

- Medical devices: PVDC is used in the production of medical devices, such as blood bags, intravenous fluid bags, and sterile packaging materials, due to its chemical resistance and ability to maintain sterility.

- Electronics: PVDC is used in the production of electronic components, such as printed circuit boards and connectors, due to its excellent electrical insulation properties and chemical resistance.

- Coatings: PVDC can be used as a coating material for various substrates, such as paper, textiles, and metals, to provide them with improved barrier properties, durability, and chemical resistance.

Environmental Concerns

Despite its many beneficial properties, PVDC has raised concerns regarding its environmental impact. The primary concern is the release of chlorine-containing compounds during the production and disposal of PVDC products, which can contribute to the formation of dioxins and other toxic substances.

To address these concerns, efforts have been made to develop more environmentally friendly alternatives to PVDC, such as biodegradable polymers and recyclable materials. Additionally, improvements in production processes and waste management practices can help to minimize the environmental impact of PVDC.

Conclusion

Polyvinylidene chloride (PVDC) is a versatile and widely used synthetic polymer that offers excellent barrier properties, chemical resistance, and durability. Its applications span various industries, including food packaging, medical devices, and electronics. However, concerns regarding its environmental impact have prompted the development of more sustainable alternatives and improvements in production and waste management practices. As research and development continue, it is likely that PVDC and its derivatives will remain an important material in a variety of applications for years to come.

Reviews

There are no reviews yet.