Description

Polyvinyl Alcohol (PVA): The Versatile Polymer Found All Around You

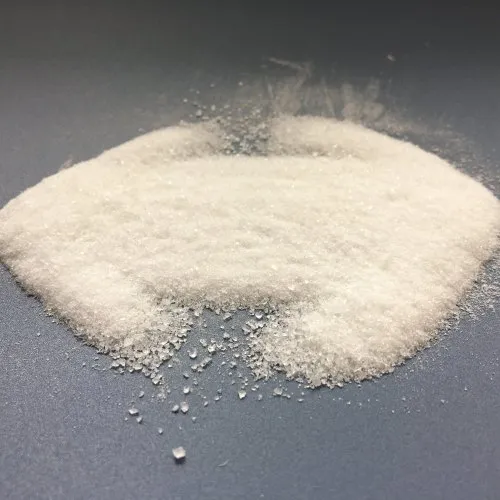

Polyvinyl alcohol (PVA), often abbreviated as PVOH, PVA, or PVAL, is a synthetic polymer with a surprisingly diverse range of applications. While it might not be a household name, PVA plays a crucial role in everything from adhesives and packaging to textiles and even medical applications. Let’s delve into the world of PVA and explore its remarkable versatility.

What is Polyvinyl Alcohol?

PVA is a water-soluble synthetic polymer produced from the hydrolysis of polyvinyl acetate (PVAc). PVAc, a common ingredient in many household items like wood glue, undergoes a chemical process called alcoholysis (hydrolysis using alcohol) to remove the acetate groups. This process yields PVA and a byproduct, typically methanol. The degree of hydrolysis – the percentage of acetate groups that are replaced with hydroxyl groups – determines PVA’s properties, influencing its water solubility, strength, and thermal stability.

Key Properties of PVA:

- Water Solubility: PVA’s defining characteristic is its water solubility, which is influenced by its molecular weight and degree of hydrolysis. This property makes it ideal for applications requiring a water-based solution or emulsion.

- Film-Forming Ability: PVA forms strong, flexible, transparent, and glossy films when dried. These films are resistant to grease, oil, and solvents, making them excellent barriers for packaging and other applications.

- Biodegradability: While not readily biodegradable under all conditions, PVA is more biodegradable than many other synthetic polymers, especially under specific environmental conditions and in the presence of certain microorganisms. This makes it a more environmentally friendly alternative in some applications.

- Adhesive Properties: PVA exhibits excellent adhesive properties, making it a suitable ingredient in various glues and binders.

- Chemical Resistance: PVA is resistant to many common solvents and chemicals, adding to its durability and longevity.

- Non-Toxic: PVA is generally considered non-toxic and biocompatible, making it suitable for applications that come into contact with food or the human body.

Applications of PVA – From Everyday to Cutting-Edge:

The unique properties of PVA have led to its widespread use in numerous industries:

- Adhesives and Binders: PVA is a common ingredient in wood glues, paper adhesives, and textile binders. Its strong bonding properties and water solubility make it a preferred choice for these applications.

- Packaging: PVA films are used as protective coatings for food packaging, particularly for single-dose packets like laundry detergent pods and edible films. Its grease resistance prevents leakage and maintains product integrity.

- Textiles: PVA is used as a sizing agent in the textile industry to strengthen yarns and improve their weaving performance. It also acts as a release agent, allowing for easier removal of coatings or patterns.

- Construction: PVA is mixed with cement to improve adhesion, flexibility, and water resistance in construction materials like plasters and mortars.

- Paper Industry: PVA is used as a coating agent to improve the surface properties of paper, enhancing print quality and providing a smoother finish.

- Medical Applications: PVA has found applications in drug delivery systems, wound dressings, and artificial organs due to its biocompatibility and film-forming ability. It can form hydrogels, which are highly absorbent and can provide a moist environment for wound healing. Surgical sponges and eye drops also utilize PVA.

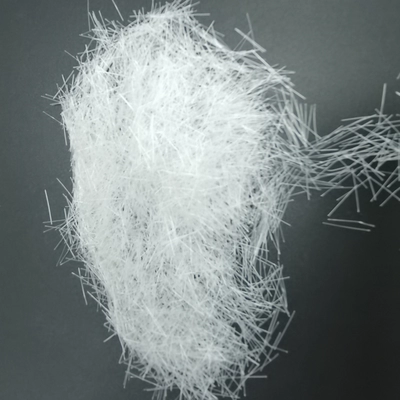

- 3D Printing: PVA is commonly used as a support material in 3D printing, specifically in dual-extrusion FDM (Fused Deposition Modeling) printers. Its water solubility allows for easy removal of the support structures without damaging the printed object.

- Fishing: PVA is used to create bags and strings in angling. Bait is placed inside the PVA bags or strung along the PVA string, and when submerged in water, the PVA dissolves, leaving the bait precisely where the angler intends.

The Future of PVA:

Research and development continue to explore new applications for PVA, focusing on its bio-based potential and further enhancing its biodegradability. Areas of interest include:

- Bioinspired Materials: Researchers are exploring the use of PVA in creating bioinspired materials that mimic natural structures and functionalities.

- Sustainable Packaging: Replacing traditional plastics with PVA-based alternatives for packaging is a growing area of focus, driven by the need for more sustainable solutions.

- Advanced Medical Devices: PVA is being explored for use in more sophisticated medical devices, such as targeted drug delivery systems and tissue engineering scaffolds.

In conclusion, polyvinyl alcohol is a truly versatile polymer with a wide range of applications impacting our daily lives. Its unique properties, combined with ongoing research and development, suggest that PVA will continue to play a significant role in various industries for years to come. From the glue holding your furniture together to the packaging protecting your food, chances are, you’ve encountered PVA today.

Reviews

There are no reviews yet.