Description

Understanding Polyurethane Dispersions: Properties, Applications, and Advantages

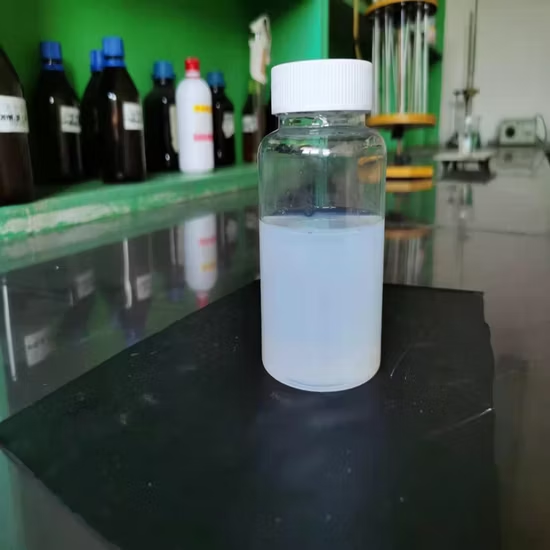

Polyurethane dispersions (PUDs) have emerged as a versatile and eco-friendly alternative to traditional solvent-based polyurethane systems. These waterborne dispersions combine the exceptional physical and chemical properties of polyurethanes with the environmental benefits of water as a dispersion medium. As industries increasingly prioritize sustainability and performance, polyurethane dispersions have become integral in coatings, adhesives, textiles, and more.

What Are Polyurethane Dispersions?

Polyurethane dispersions are stable aqueous suspensions of polyurethane polymers. Unlike conventional polyurethanes, which are often dissolved in organic solvents, PUDs use water as the continuous phase. This approach significantly reduces the emission of volatile organic compounds (VOCs), making these materials more environmentally friendly and compliant with stringent environmental regulations.

The polyurethane polymer in a dispersion is synthesized via step-growth polymerization of diisocyanates and polyols, often incorporating hydrophilic groups or chain extenders to ensure water dispersibility. The resulting particles are typically in the size range of 100 to 300 nanometers, dispersed uniformly in water.

Key Properties of Polyurethane Dispersions

Polyurethane dispersions exhibit a unique combination of properties that make them highly desirable for a variety of applications:

- Flexibility and Elasticity: PUD films are known for their excellent flexibility, elongation, and toughness, which contribute to durable coatings and adhesives.

- Chemical Resistance: These dispersions provide good resistance to oils, solvents, and chemicals, protecting substrates effectively.

- Adhesion: PUDs adhere well to a wide range of substrates, including metals, plastics, fabrics, and wood.

- Abrasion Resistance: The films formed from PUDs offer strong wear resistance, enhancing durability in demanding applications.

- Low VOC Emissions: Using water as the dispersion medium minimizes harmful emissions, enabling safer indoor air quality and compliance with environmental standards.

Applications of Polyurethane Dispersions

Due to their outstanding performance and environmental advantages, polyurethane dispersions are used extensively across several sectors:

- Coatings: PUDs are widely employed in architectural, automotive, and industrial coatings. Their ability to form tough, flexible films makes them excellent candidates for protective and decorative finishes.

- Textiles: In textile finishing, PUDs enhance fabric softness, water repellency, and durability, improving comfort and performance.

- Adhesives and Sealants: Waterborne polyurethane adhesives provide strong bonding strength with less environmental impact compared to solvent-based adhesives.

- Leather Finishing: PUDs are popular in leather coatings due to their flexibility and resistance properties, which improve the feel and longevity of leather goods.

- Paper and Packaging: They improve water resistance and mechanical properties of paper-based materials, contributing to sustainable packaging solutions.

Advantages Over Traditional Polyurethane Systems

Traditional polyurethane formulations often rely on organic solvents, which pose environmental and health risks due to VOC emissions. Polyurethane dispersions address these concerns by offering:

- Eco-friendly Profiles: Reduced VOC content aligns with global trends towards greener chemistry and sustainable manufacturing.

- Safer Handling: Waterborne systems are less flammable and safer to handle during processing and application.

- Regulatory Compliance: PUDs help manufacturers meet increasingly strict environmental guidelines without sacrificing product performance.

- Versatility in Formulation: PUDs can be engineered to exhibit a broad range of mechanical and chemical properties tailored to specific application needs.

Challenges and Future Outlook

While polyurethane dispersions continue to grow in popularity, some challenges remain, including the complexity of formulation, achieving long-term stability, and balancing performance characteristics like water resistance and flexibility.

Ongoing research aims to develop next-generation PUDs with improved biodegradability, higher solids content for faster drying, and enhanced functional properties such as antimicrobial activity or self-healing. Advances in green chemistry and nanotechnology promise to further extend the applications and environmental benefits of polyurethane dispersions.

Conclusion

Polyurethane dispersions represent a significant advancement in polymer technology, merging the superior performance of polyurethanes with environmental responsibility. Their unique properties and broad applicability make them essential materials in modern industries focused on sustainability and high performance. As technology progresses, PUDs are poised to play a pivotal role in shaping the future of coatings, adhesives, textiles, and beyond.

Reviews

There are no reviews yet.