Description

Title: Polyetheretherketone (PEEK): A High-Performance Engineering Thermoplastic

Introduction

Polyetheretherketone (PEEK) is a high-performance engineering thermoplastic with a unique combination of mechanical, chemical, and thermal properties. It belongs to the polyaryletherketone (PAEK) family of polymers and is known for its exceptional resistance to thermal degradation, abrasion, and chemical attack, making it an ideal material for various demanding applications. This article explores the properties, processing, applications, and advantages of PEEK, providing insights into its significance in the modern engineering landscape.

Properties of PEEK

PEEK is characterized by its outstanding mechanical properties, including high strength, stiffness, and toughness. It exhibits a tensile strength of up to 200 MPa, a flexural modulus of 3.6 GPa, and an impact strength of 20 kJ/m² (notched Izod). Moreover, PEEK’s excellent fatigue resistance and creep resistance enable it to maintain its structural integrity under dynamic loading conditions and at elevated temperatures.

PEEK’s chemical resistance is remarkable, as it is unaffected by most organic solvents, acids, and bases. It can withstand temperatures up to 250°C for short periods and 160-170°C for long-term exposure without significant loss of mechanical properties. PEEK also exhibits excellent electrical insulation properties and low moisture absorption, making it suitable for applications requiring high dielectric strength and dimensional stability.

Processing of PEEK

PEEK can be processed using various techniques, including injection molding, extrusion, compression molding, and additive manufacturing. The material’s high melting point (343°C) and viscosity necessitate the use of specialized equipment and processing conditions to ensure proper melt flow and part formation.

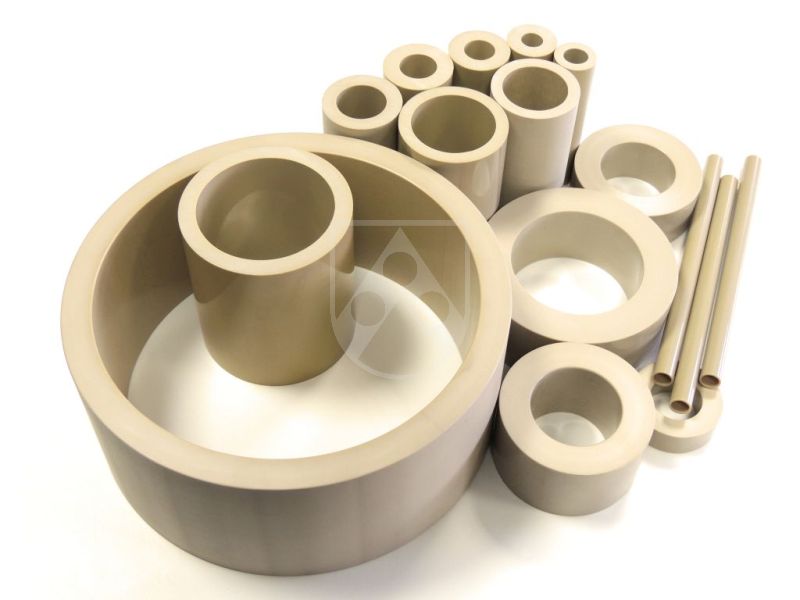

Injection molding is the most common processing method for PEEK, offering high production rates and excellent part reproducibility. The material’s low mold shrinkage (0.3-0.5%) facilitates precise dimensional control and minimizes post-molding warpage. Extrusion is used to produce PEEK profiles, tubes, and films, while compression molding is employed for manufacturing large, complex parts or laminates.

Additive manufacturing, or 3D printing, has emerged as a promising processing technique for PEEK. Fused deposition modeling (FDM), selective laser sintering (SLS), and multi-jet fusion (MJF) are some of the 3D printing methods used for PEEK. These techniques enable the production of complex geometries, customized components, and functional prototypes with high accuracy and resolution.

Applications of PEEK

PEEK’s unique combination of properties makes it an ideal material for various applications across different industries, including aerospace, automotive, medical, oil and gas, and electrical and electronics.

Aerospace: PEEK’s high strength-to-weight ratio, chemical resistance, and fire retardancy make it an excellent choice for aerospace components such as fuel system components, electrical insulators, and structural parts.

Automotive: In the automotive industry, PEEK is used in the production of fuel system components, oil pump gears, and electrical connectors, contributing to weight reduction, improved fuel efficiency, and enhanced durability.

Medical: PEEK’s biocompatibility, radiopacity, and sterilizability make it a popular material for medical applications such as spinal implants, dental implants, and orthopedic devices.

Oil and Gas: PEEK’s exceptional resistance to harsh chemicals and high temperatures makes it suitable for oil and gas applications, including downhole tools, seals, and valve components.

Electrical and Electronics: PEEK’s low moisture absorption, high dielectric strength, and excellent electrical insulation properties make it an ideal material for electrical and electronics applications, such as connectors, insulators, and heat dissipation components.

Advantages of PEEK

PEEK offers numerous advantages over traditional engineering materials, including:

- High strength, stiffness, and toughness

- Excellent chemical resistance and thermal stability

- Low moisture absorption and good electrical insulation properties

- High-temperature performance and dimensional stability

- Biocompatibility and sterilizability (for medical applications)

- Recyclability and environmental sustainability

Conclusion

Polyetheretherketone (PEEK) is a versatile high-performance engineering thermoplastic with a unique combination of mechanical, chemical, and thermal properties. Its exceptional resistance to thermal degradation, abrasion, and chemical attack makes it an ideal material for various demanding applications across different industries. With its high-temperature performance, dimensional stability, and excellent electrical insulation properties, PEEK continues to gain prominence in the modern engineering landscape, offering designers and engineers a reliable and sustainable solution for advanced manufacturing challenges.

Reviews

There are no reviews yet.