Description

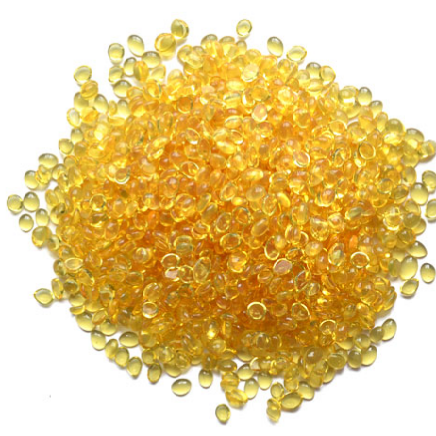

Polyamide Resin

Polyamide resin refers to a broad family of polymers containing amide linkages (-CO-NH-) in their backbone. They are commonly known as nylons in their thermoplastic form, but the term also covers higher-performance polyamide-based resins used in coatings, adhesives, and advanced composites. The class includes simple nylons (PA6, PA66, PA12, etc.) as well as higher-performance derivatives like polyamide-imide (PAI) and related materials.

What makes polyamide resins unique

- Strength and toughness: Strong, abrasion-resistant materials with good impact resistance.

- Chemical resistance: Generally good resistance to hydrocarbons and many solvents.

- Moisture sensitivity: Many nylons absorb moisture from the environment, which can affect dimensional stability and mechanical properties.

- Thermal behavior: Melting temperatures and service temperatures vary by grade; performance can be tailored by blending or adding modifiers.

- Processing versatility: Can be melt-processed (injection molding, extrusion) or processed as powders/films for coatings and additive manufacturing.

Common types and their highlights

| Type | Key features | Typical processing methods | Common applications |

|---|---|---|---|

| PA6 (Nylon 6) | Balanced toughness and processability; moderate heat resistance | Injection molding, extrusion, some 3D printing | Automotive parts, gears, housings, consumer electronics housings |

| PA66 (Nylon 66) | Higher stiffness and heat resistance than PA6 | Injection molding, extrusion | Under-hood automotive components, wear parts, mechanical housings |

| PA12 (Nylon 12) | Lower moisture uptake, better chemical resistance, greater flexibility | Extrusion, film, injection molding; 3D printing (PA12) | Fluid lines, tubing, flexible parts, packaging films |

| PAI (Polyamide-Imide) | Very high temperature resistance and mechanical strength | Castings, high-temp coatings, specialty parts | Aerospace, electronics, high-temp components |

| Other variations | Additives and co-polymers yield improved wear, UV stability, or moisture performance | Customized processing routes | Specialized applications across automotive, electronics, and industrial sectors |

Note: PA6, PA66, and PA12 are the most commonly used industrial nylons. PAI represents a higher-performance subset within the broader polyamide family.

Processing and fabrication

- Thermoplastic nylons (PA6, PA66, PA12) are typically melt-processed:

- Injection molding for complex shapes

- Extrusion for profiles, sheets, and films

- Some nylons are compatible with 3D printing (notably PA12 powders for selective laser sintering)

- Coatings and adhesives may use polyamide resins as a base or binder, often in formulations that cure with crosslinkers to achieve specific gloss, hardness, and chemical resistance.

- Moisture management is important: drying polymers prior to processing is common to minimize hydrolytic degradation and dimensional changes.

- Blends and additives (e.g., glass fibers for stiffness, lubricants for wear resistance, UV stabilizers for outdoors use) are frequently employed to meet specific application requirements.

Properties at a glance

- Mechanical: Good strength and wear resistance; toughness varies by grade.

- Thermal: Service temperature depends on grade; PA66 generally tolerates higher temperatures than PA6 or PA12.

- Chemical: Generally good resistance to hydrocarbons; resistance to some solvents depends on formulation.

- Hygroscopicity: Moisture uptake can affect stiffness and dimensions; hygroscopicity is an important design consideration.

- Electrical: Good insulating properties, though moisture can alter performance.

Selection tips

- If you need high heat resistance and stiffness, consider PA66 or higher-performance options like PAI.

- If moisture sensitivity is a concern in your part, PA12 often offers better dimensional stability and chemical resistance.

- For 3D printing or rapid prototyping, PA12 powders are a common choice, while PA6/PA66 are well-established in traditional molding.

- For coatings or adhesives, identify whether a polyamide resin is used as a binder or as part of a crosslinking system and select compatible curing chemistry.

Quick takeaways

- Polyamide resins cover a broad range from typical nylons (PA6, PA66, PA12) to high-performance polyamide-imides.

- They offer a strong balance of mechanical performance and chemical resistance, with moisture sensitivity being a key design consideration.

- Processing routes vary from conventional melt processing to specialized coating or additive manufacturing formulations.

If you can share the specific grade, application (e.g., coating, coating binder, 3D printing, mechanical part), or processing method you’re interested in, I can tailor the details, provide typical data (tensile strength, modulus, Tg, etc.), and point you to relevant datasheets.

Reviews

There are no reviews yet.