Description

Phosphoric Acid: A Cornerstone Chemical in Semiconductor Manufacturing

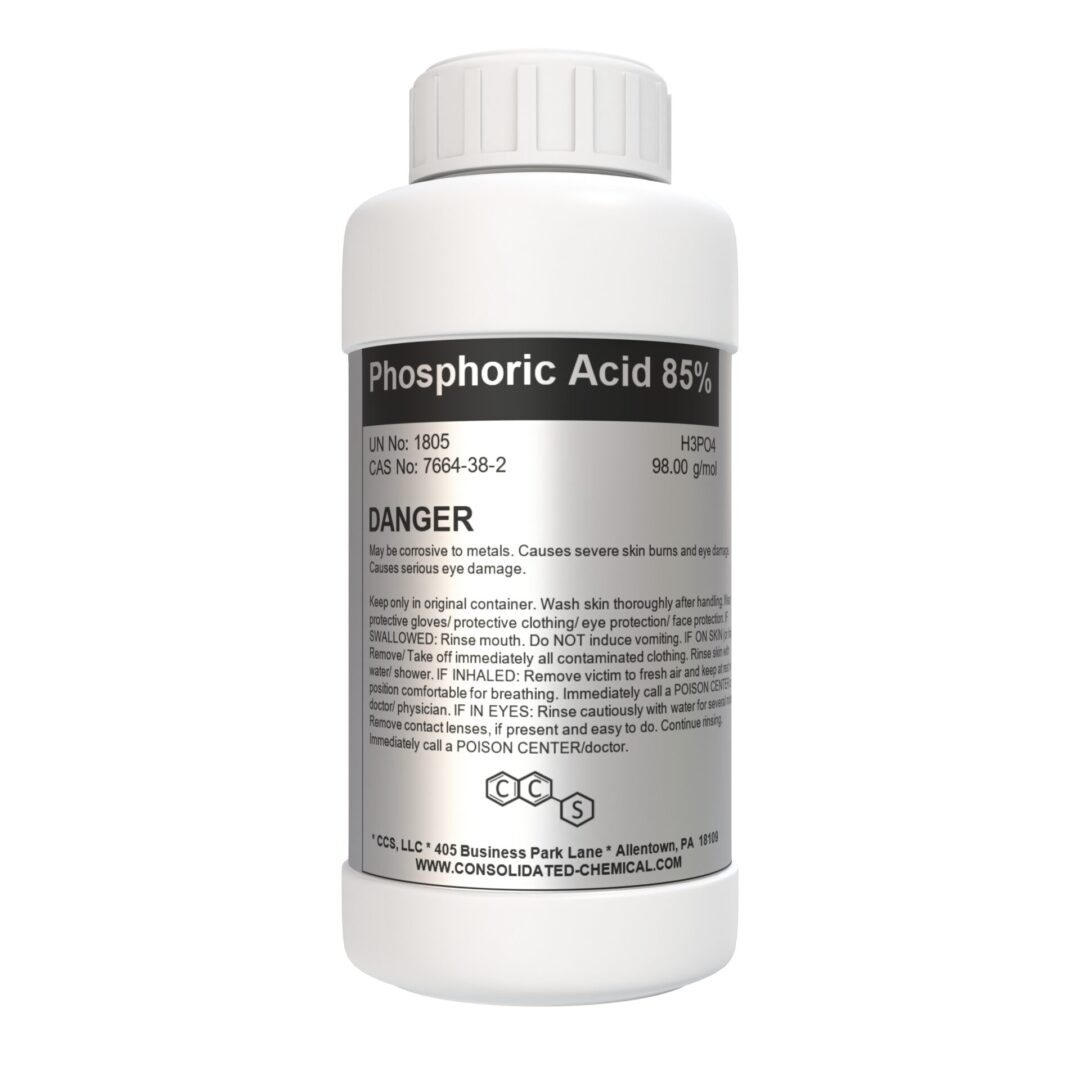

In the intricate world of semiconductor manufacturing, where precision and purity are paramount, a seemingly simple chemical plays a vital role: phosphoric acid. While often overlooked, phosphoric acid (H₃PO₄) is an indispensable component in numerous critical processes, contributing to the creation of the microchips that power our modern lives. This article delves into the multifaceted uses of phosphoric acid in this highly demanding industry.

Why Phosphoric Acid? Properties and Advantages

Phosphoric acid is a weak mineral acid known for its stability, relatively low toxicity compared to other acids, and its effectiveness as an etchant and cleaning agent. Its properties make it uniquely suited for several key applications in semiconductor fabrication:

- Etching: Phosphoric acid is primarily used as an etchant for materials like silicon nitride (Si₃N₄) and aluminum. Its ability to selectively remove these materials without significantly attacking other materials like silicon dioxide (SiO₂) is crucial for creating intricate circuit patterns on the wafer.

- Cleaning: The stringent cleanliness requirements of semiconductor manufacturing demand ultrapure chemicals. Phosphoric acid is used in cleaning solutions to remove contaminants, particulate matter, and residual metals from wafer surfaces, ensuring optimal performance.

- Surface Preparation: Prior to deposition processes like thin film deposition, phosphoric acid can be used to prepare the wafer surface, promoting better adhesion and uniformity of the deposited layers.

- pH Adjustment and Buffering: In some plating and electrochemical processes, phosphoric acid is used to control and maintain the pH of the solution, ensuring the desired reaction conditions.

Key Applications in Semiconductor Fabrication:

Let’s explore some specific examples of how phosphoric acid is used in semiconductor manufacturing:

- Silicon Nitride Etching: One of the most common applications is the selective etching of silicon nitride layers. Phosphoric acid, typically used at elevated temperatures (around 160°C), etches silicon nitride at a controlled rate, allowing for the precise creation of openings and patterns for subsequent processing steps.

- Aluminum Etching and Cleaning: While stronger acids are often used for bulk aluminum removal, phosphoric acid can be used in cleaning formulations to remove aluminum residues and ensure a clean surface prior to further processing.

- Wet Benches: Phosphoric acid is a staple in wet bench cleaning processes, which are crucial for removing contaminants after various fabrication steps like lithography, etching, and deposition.

- Residue Removal: Post-etch residue removal is critical to prevent defects in the final product. Formulations containing phosphoric acid are used to effectively dissolve and remove these residues.

Challenges and Considerations:

While indispensable, the use of phosphoric acid in semiconductor manufacturing presents certain challenges:

- Purity Requirements: Impurities in phosphoric acid can negatively impact device performance. Therefore, only ultrapure, semiconductor-grade phosphoric acid is used, requiring stringent quality control and purification processes.

- Waste Disposal and Environmental Concerns: Phosphoric acid waste must be handled and disposed of responsibly to minimize environmental impact. Recycling and neutralization processes are often employed to mitigate these concerns.

- Corrosion: While relatively mild compared to stronger acids, concentrated phosphoric acid can corrode certain materials. Proper material selection for equipment and handling systems is essential.

The Future of Phosphoric Acid in Semiconductor Manufacturing:

As the semiconductor industry continues to evolve, with ever-shrinking feature sizes and increasingly complex device architectures, the demands on chemicals like phosphoric acid will only intensify. Research and development efforts are focused on:

- Improving Purity Levels: Pushing the boundaries of purity to meet the increasingly stringent requirements of advanced microchip fabrication.

- Developing Enhanced Formulations: Creating custom phosphoric acid formulations tailored to specific etching and cleaning needs.

- Optimizing Waste Management: Finding more efficient and sustainable ways to recycle and dispose of phosphoric acid waste.

Conclusion:

Phosphoric acid is a vital, albeit unsung, hero in the complex and demanding world of semiconductor manufacturing. Its unique properties make it an essential component in etching, cleaning, and surface preparation processes. By understanding its role and addressing the challenges associated with its use, the semiconductor industry can continue to leverage this versatile chemical to create the advanced microchips that drive technological innovation.

Reviews

There are no reviews yet.