Description

Niobium Ethoxide: A Key Precursor in the World of Advanced Materials

In the intricate landscape of advanced materials science, certain chemical compounds serve as indispensable building blocks, enabling the creation of cutting-edge technologies. Among these, Niobium Ethoxide, with the chemical formula Nb(OC2H5)5 or Nb(OEt)5, stands out as a highly versatile and widely utilized precursor. This alkoxide of niobium is a cornerstone in the synthesis of high-purity niobium-based materials, from thin films and coatings to ceramics and catalysts.

What is Niobium Ethoxide?

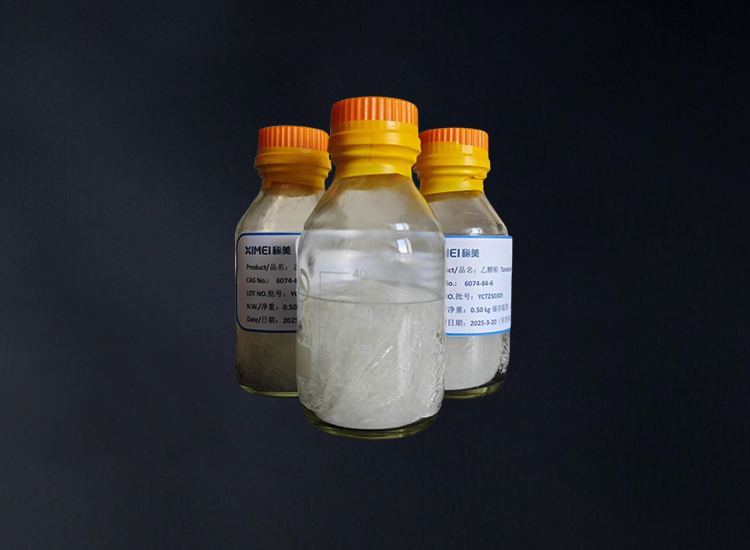

Niobium Ethoxide is an organometallic compound, specifically a metal alkoxide, where five ethoxide (–OC2H5) groups are covalently bonded to a central niobium atom. At room temperature, it typically exists as a colorless to pale yellow liquid, readily soluble in many organic solvents. Its molecular structure makes it highly reactive, particularly with moisture, a characteristic that is both a challenge and an advantage in its applications.

Chemical Profile and Synthesis

Formula: Nb(OC2H5)5 or Nb(OEt)5 Appearance: Colorless to pale yellow liquid Boiling Point: Approximately 350-360 °C (decomposes before boiling at atmospheric pressure without reduced pressure) Reactivity: Highly sensitive to moisture (hydrolysis), reacts with alcohols and other protic solvents.

Niobium Ethoxide is commonly synthesized through the reaction of niobium pentachloride (NbCl5) with anhydrous ethanol, often in the presence of a base (like ammonia) to neutralize the hydrochloric acid byproduct. The reaction typically proceeds as follows:

NbCl5 + 5 C2H5OH + 5 NH3 → Nb(OC2H5)5 + 5 NH4Cl

The product is then typically purified by distillation under reduced pressure to obtain a high-purity precursor.

The Power of a Precursor: Key Applications

The primary utility of Niobium Ethoxide lies in its role as a precursor for the synthesis of various niobium-containing materials, primarily through sol-gel processing, chemical vapor deposition (CVD), and atomic layer deposition (ALD).

- Sol-Gel Process: This is perhaps the most significant application. Niobium Ethoxide readily undergoes hydrolysis and condensation reactions when exposed to water, forming a gel that, upon calcination (heating), transforms into high-purity niobium pentoxide (Nb2O5) or other complex niobium oxides. The sol-gel method offers several advantages:

- Low Processing Temperatures: Relative to traditional ceramic methods, sol-gel allows for material synthesis at much lower temperatures.

- High Purity & Homogeneity: The molecular-level mixing in the solution phase ensures a high degree of purity and uniform composition in the final material.

- Versatile Forms: Enables the creation of powders, thin films, fibers, and bulk materials with controlled nanostructures.

- Thin Films and Coatings: Due to its volatility, Niobium Ethoxide is an excellent candidate for gas-phase deposition techniques like CVD and ALD. These techniques are used to produce:

- Optical Coatings: Niobium pentoxide films are highly transparent and possess a high refractive index, making them ideal for anti-reflection coatings, optical filters, and waveguides.

- Dielectric Layers: In electronics, Nb2O5 films are used as high-k dielectric materials in capacitors and memory devices, offering efficient charge storage due to their high dielectric constant.

- Protective Layers: Coatings for enhanced corrosion resistance and durability.

- Catalysis: Niobium Ethoxide serves as a precursor for the preparation of various niobium-based catalysts. Niobium oxides, often in combination with other metal oxides, exhibit excellent catalytic properties for reactions such as:

- Oxidation reactions

- Acid-catalyzed reactions

- Photocatalysis (e.g., water splitting, pollutant degradation)

- Advanced Ceramics: Beyond pure niobium oxide, Niobium Ethoxide is used to synthesize more complex niobate ceramics, such as:

- Lithium Niobate (LiNbO3): A widely used ferroelectric and piezoelectric material for optical modulators, surface acoustic wave (SAW) devices, and non-linear optics.

- Barium Titanate-Niobate (BaTiO3-Nb): Used in high-performance capacitors and sensors.

- Lead Magnesium Niobate (PMN): For electrostrictive actuators and transducers.

Advantages and Considerations

Advantages:

- High Purity: Niobium Ethoxide allows for the synthesis of highly pure materials, crucial for advanced applications.

- Low Temperature Processing: Enables the formation of materials at temperatures significantly lower than conventional methods.

- Molecular-Level Control: Offers precise control over stoichiometry and homogeneity.

- Versatility: Applicable to various synthesis techniques (sol-gel, CVD, ALD).

Considerations:

- Moisture Sensitivity: Its extreme reactivity with water requires handling under inert atmosphere (argon or nitrogen) to prevent premature hydrolysis and precipitation.

- Cost: As a specialty chemical, it can be more expensive than simpler niobium precursors.

- Flammability: The ethoxide groups make it flammable, requiring careful handling and storage.

Safety and Handling

Due to its sensitivity to moisture and flammability, Niobium Ethoxide must be handled with extreme care. It should be stored in tightly sealed containers under an inert atmosphere. Personal protective equipment (PPE) such as gloves, safety glasses, and a lab coat are essential. Reactions involving Niobium Ethoxide should be conducted in a well-ventilated fume hood.

Future Prospects

Niobium Ethoxide continues to be an active area of research. Its role is expanding in the development of:

- Next-generation energy storage devices: High-performance batteries and supercapacitors.

- Advanced semiconductors: For transparent electronics and flexible devices.

- Biomedical applications: Biocompatible coatings and drug delivery systems.

- Environmental technologies: More efficient catalysts for pollution control and sustainable energy production.

Conclusion

Niobium Ethoxide is far more than just a chemical; it is a critical enabling technology for modern materials science. Its unique chemical properties allow for the precise and efficient fabrication of a wide array of niobium-based materials with tailored properties, driving innovation across electronics, optics, catalysis, and beyond. As the demand for advanced materials continues to grow, Niobium Ethoxide will undoubtedly remain a cornerstone in the chemist’s and material scientist’s toolkit, shaping the technologies of tomorrow.

Reviews

There are no reviews yet.