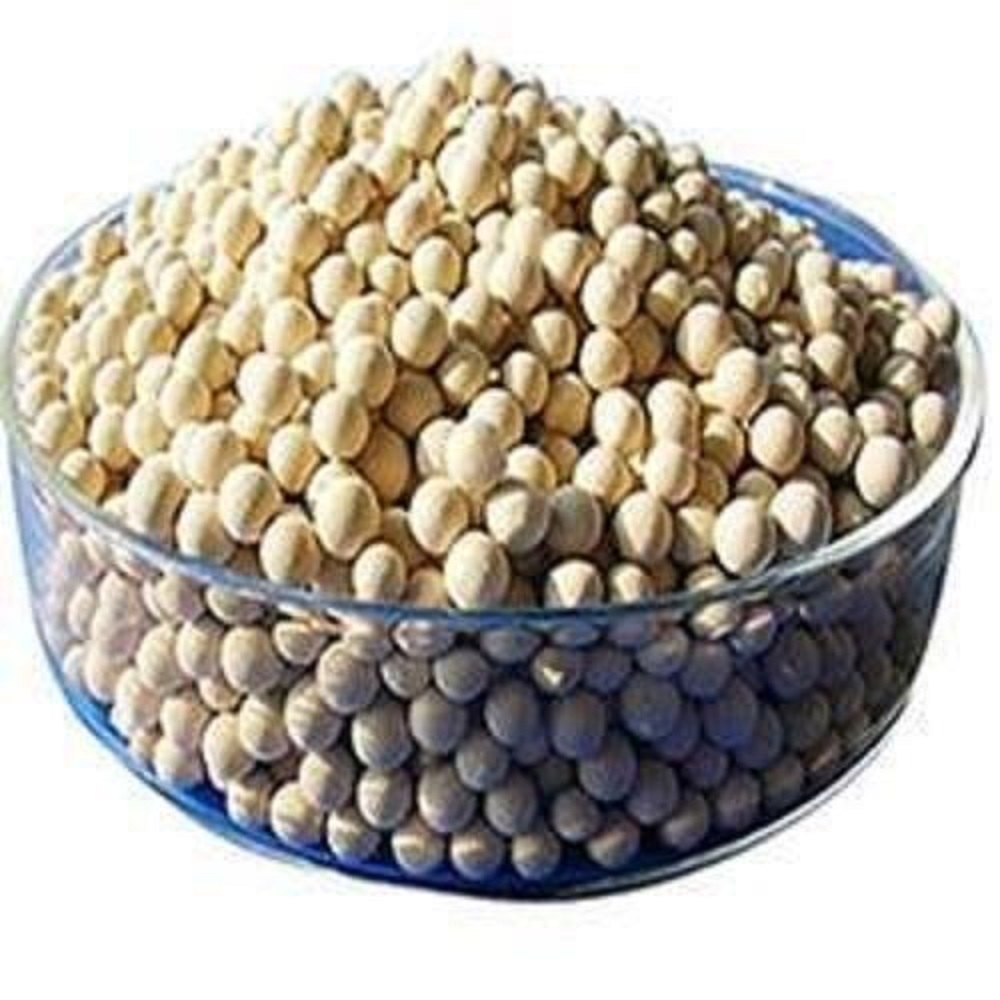

Description

Molecular Sieves: Your Secret Weapon for Alcohol Purification and Drying

In the world of chemistry, pharmaceuticals, and biofuel production, the purity and dryness of alcohols are paramount. Trace amounts of water or unwanted byproducts can drastically impact reaction outcomes, product stability, and overall quality. Enter molecular sieves, the unsung heroes working at the molecular level to ensure your alcohols meet the highest standards.

What are Molecular Sieves?

Imagine a material riddled with precisely sized pores, acting like a microscopic strainer. That’s essentially what a molecular sieve is. These synthetic or naturally occurring crystalline aluminosilicates (zeolites) offer a unique ability to selectively adsorb molecules based on their size and polarity. This selective adsorption makes them incredibly effective for separating and purifying substances, especially alcohols.

How Molecular Sieves Work for Alcohol Purification:

The magic of molecular sieves lies in their pore size. By carefully selecting a sieve with a pore size that’s larger than water but smaller than the alcohol you’re interested in, you can selectively trap the water molecules within the sieve’s structure. Here’s a breakdown of the process:

- Adsorption: The alcohol mixture is contacted with the molecular sieve. Water molecules, being smaller, enter the pores and are adsorbed onto the internal surface.

- Exclusion: Larger molecules, including the alcohol itself (and potentially other contaminants depending on the sieve’s pore size) are excluded from entering the pores due to their size.

- Separation: The result is a purified and significantly drier alcohol stream.

Key Advantages of Using Molecular Sieves for Alcohol Treatment:

Compared to other methods like distillation or solvent extraction, molecular sieves offer several compelling advantages:

- High Selectivity: Extremely effective in removing trace amounts of water, achieving very high purity levels.

- Efficiency: Can achieve lower water content than distillation, particularly for azeotropic mixtures.

- Energy Efficiency: Typically requires less energy than distillation, making it a more sustainable option.

- Regeneration: Molecular sieves can be regenerated by heating them under vacuum or purging with a dry gas. This allows for repeated use, making them economically viable.

- Versatility: Suitable for a wide range of alcohols, from ethanol and methanol to isopropanol and butanol.

Choosing the Right Molecular Sieve:

Selecting the correct molecular sieve is crucial for optimal performance. Factors to consider include:

- Pore Size: The pore size must be carefully matched to the size of the alcohol molecule you wish to purify and the contaminants you want to remove. Common pore sizes for alcohol drying include 3A (0.3 nm) and 4A (0.4 nm).

- Type of Alcohol: Different alcohols interact differently with the sieve material. Factors like polarity and functional groups influence adsorption characteristics.

- Concentration of Water: The initial water content of the alcohol mixture will impact the amount of sieve needed and the frequency of regeneration.

- Operating Conditions: Temperature, pressure, and flow rate all play a role in the efficiency of the adsorption process.

Applications of Molecular Sieves in Alcohol Processing:

The applications of molecular sieves in alcohol processing are widespread and diverse:

- Ethanol Dehydration: Essential for producing anhydrous ethanol for use as a biofuel or solvent.

- Pharmaceutical Manufacturing: Ensuring the purity of alcohol-based solvents used in drug synthesis and formulations.

- Chemical Synthesis: Removing water from reaction mixtures to improve yields and selectivity.

- Beverage Production: Improving the quality and stability of alcoholic beverages.

- Biofuel Production: Refining and purifying bio-alcohols produced from sustainable sources.

Beyond Water Removal:

While primarily known for moisture removal, molecular sieves can also be used for:

- Separating Alcohol Mixtures: Selecting a sieve that adsorbs one alcohol more readily than another allows for the separation of complex mixtures.

- Removing Organic Contaminants: Certain sieves can selectively adsorb specific organic impurities, further enhancing the purity of the alcohol.

Conclusion:

Molecular sieves provide a powerful and versatile tool for achieving exceptionally high levels of purity and dryness in alcohol processing. Their selective adsorption capabilities, efficiency, and regenerability make them an indispensable component in various industries. By understanding the principles behind their operation and carefully selecting the appropriate sieve type, you can unlock the full potential of this remarkable technology and ensure the quality and performance of your alcohol-based products and processes.

Reviews

There are no reviews yet.