Description

Methyl Methacrylate (MMA): The Invisible Force Behind Clarity and Durability

Methyl methacrylate (MMA) might not be a household name, but its impact on our daily lives is undeniable. This versatile chemical compound serves as the fundamental building block for a vast array of modern materials, most notably the transparent, durable sheets we often refer to as acrylic glass or Plexiglas. From aircraft windows to dental fillings, MMA’s influence is clear, strong, and surprisingly widespread.

What is Methyl Methacrylate (MMA)?

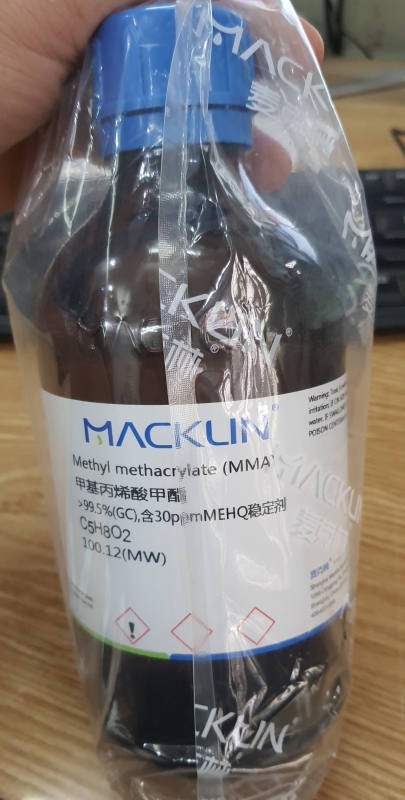

MMA is an organic compound with the chemical formula CH₂=C(CH₃)COOCH₃. At room temperature, it’s a clear, colorless liquid with a distinct, somewhat fruity odor. Its most notable characteristic, and the key to its industrial importance, is the presence of a double bond in its molecular structure, which allows it to undergo a process called polymerization. In this process, individual MMA molecules (monomers) link together repeatedly to form long chains, creating a much larger molecule known as a polymer.

The Powerhouse Polymer: PMMA (Acrylic Glass)

The vast majority of MMA produced worldwide is polymerized into polymethyl methacrylate (PMMA), more commonly known as acrylic glass, acrylic, Plexiglas, Lucite, or Perspex. This material is a remarkable alternative to traditional glass and plastics, boasting a unique combination of properties:

- Exceptional Transparency: PMMA transmits over 90% of visible light, making it optically clear and an excellent choice for applications requiring clarity.

- High Impact Strength: While glass shatters, PMMA is significantly more shatter-resistant, making it safer in many applications.

- Lightweight: It’s less than half the weight of glass, reducing structural load and making handling easier.

- Weather and UV Resistance: PMMA withstands prolonged exposure to sunlight and outdoor elements without significant degradation or yellowing, unlike many other plastics.

- Scratch Resistance: Although it can scratch, PMMA’s surface hardness is superior to many other plastics, and minor scratches can often be buffed out.

- Ease of Fabrication: It can be easily cut, drilled, molded, and thermoformed into various shapes.

These properties make PMMA indispensable in countless applications, including:

- Architecture and Construction: Skylights, windows (especially in demanding environments like aquariums and aircraft), safety glazing, decorative panels.

- Automotive: Tail lights, interior trim, instrument panels.

- Lighting: Diffusers, light guides, LED lighting components.

- Displays: Retail displays, signboards, protective screens.

- Medical and Dental: Incubators, dental prosthetics, bone cement, surgical instruments.

- Consumer Goods: Furniture, tableware, eyewear lenses, cosmetic packaging.

Beyond Acrylic Glass: Diverse Applications

While PMMA dominates, MMA itself and its other polymer forms find applications in a surprisingly broad range of industries:

- Adhesives and Sealants: MMA is a key ingredient in many industrial and medical adhesives, including those used in dental composites for fillings and in specialized bone cements for orthopedic surgery.

- Coatings and Paints: It’s used in high-performance coatings, lacquers, and paints for various surfaces, offering durability, gloss, and weather resistance.

- Inks: MMA-based resins improve the adhesion and durability of printing inks.

- Textiles and Fabrics: It can be used in certain textile treatments to enhance properties like stiffness or water resistance.

- Artificial Nails: The classic “liquid and powder” system for acrylic nails relies on MMA (the liquid monomer) reacting with a PMMA powder to form a strong, durable nail extension.

Production and Safety Considerations

MMA is produced on a massive industrial scale, primarily through processes involving acetone cyanohydrin or newer, more environmentally friendly routes.

As a chemical, MMA requires careful handling. It is a flammable liquid and its vapors can be irritating to the skin, eyes, and respiratory system. Prolonged or repeated exposure can lead to sensitization in some individuals. In industrial settings, strict safety protocols, including proper ventilation and personal protective equipment, are essential to ensure the safety of workers.

From an environmental perspective, ongoing research focuses on developing more sustainable production methods for MMA and improving the recyclability of PMMA to minimize waste and environmental impact.

Conclusion

Methyl methacrylate, the unassuming liquid monomer, is a cornerstone of modern material science. Its ability to transform into PMMA has revolutionized industries from automotive to healthcare, providing materials that are clearer, stronger, lighter, and more versatile than many traditional alternatives. As we continue to seek innovative solutions for future challenges, MMA’s role as a fundamental building block for advanced materials ensures its continued relevance and pervasive influence in our increasingly engineered world.

Reviews

There are no reviews yet.