Description

Industrial Grade Sheets: The Backbone of Countless Applications

In the often-unseen world of manufacturing, construction, and engineering, industrial grade sheets play a vital, yet crucial role. These versatile materials serve as the foundation for countless applications, ranging from machine guards to structural components, and everything in between. But what exactly defines an “industrial grade” sheet, and why are they so essential?

What Makes a Sheet “Industrial Grade?”

The term “industrial grade” implies a level of durability, performance, and consistency that goes beyond that of consumer-grade materials. Factors that contribute to this classification include:

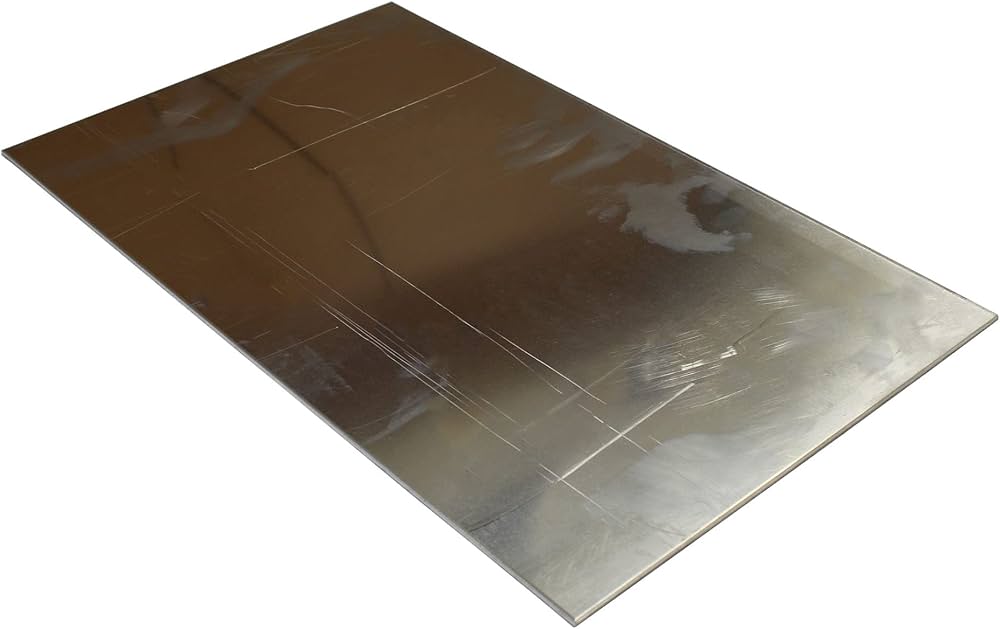

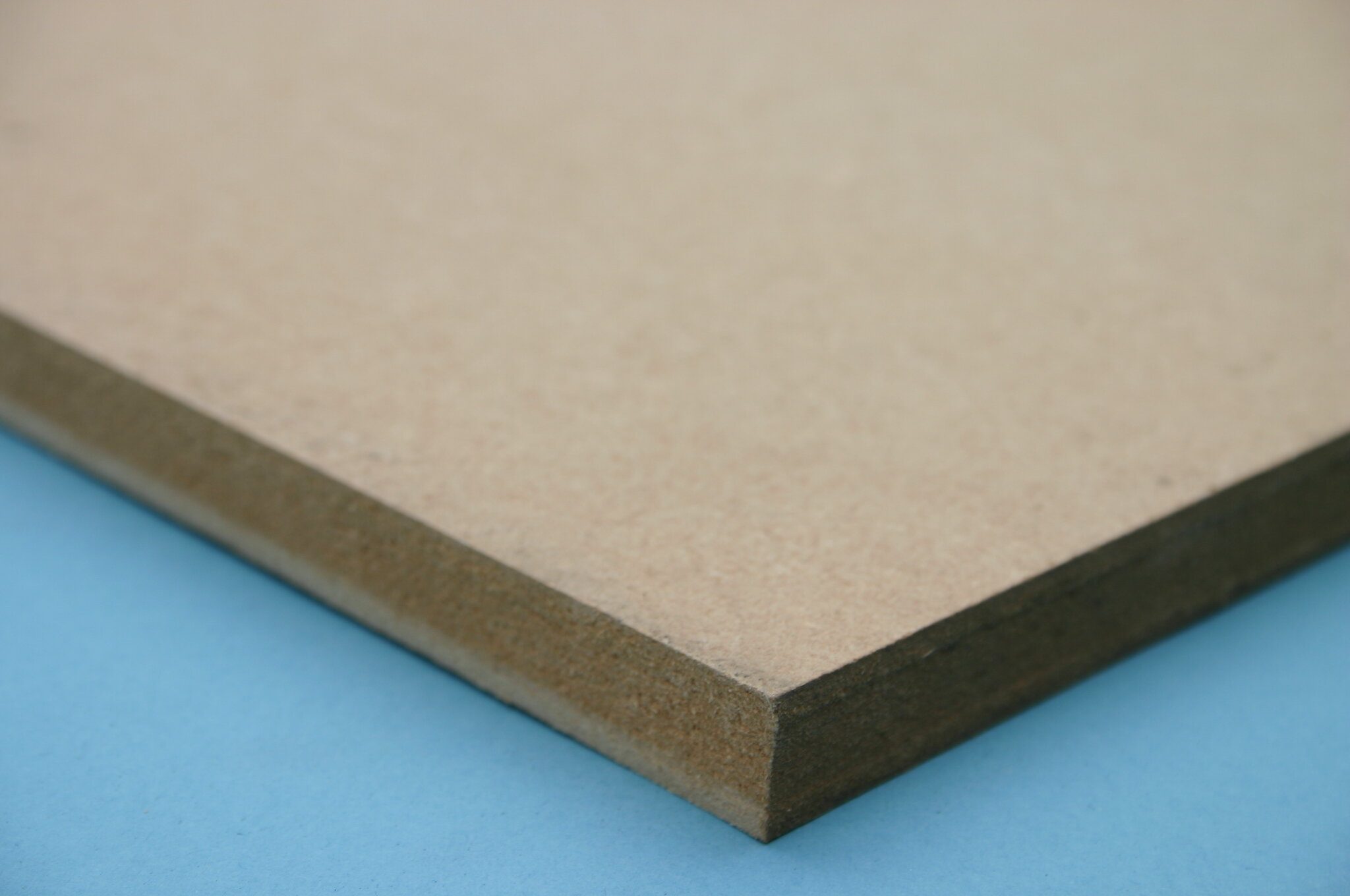

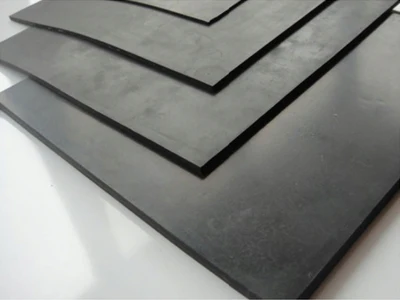

- Material Composition: Industrial grade sheets are typically manufactured from robust materials like steel (including stainless steel), aluminum, various plastics (polycarbonate, acrylic, PVC, UHMW), and even specialized composites. The specific material is selected based on the application’s requirements for strength, corrosion resistance, temperature tolerance, and other performance characteristics.

- Manufacturing Process: These sheets are often produced using specific methods that ensure uniformity in thickness, density, and finish. This controlled manufacturing is critical for predictable performance and consistent quality.

- Compliance and Standards: Industrial grade sheets often adhere to industry standards and certifications, guaranteeing they meet specific performance criteria and safety regulations. These certifications can vary depending on the application and region.

- Durability and Longevity: Engineered for demanding environments, industrial grade sheets are built to withstand wear, tear, and exposure to harsh conditions. This robustness translates to a longer lifespan and reduced maintenance costs.

The Versatile Applications of Industrial Grade Sheets:

The adaptability of industrial grade sheets makes them indispensable across a wide range of industries. Here are just a few prominent examples:

- Manufacturing: Used for machine guards, conveyor systems, work surfaces, and enclosures, protecting both personnel and equipment.

- Construction: Found in roofing, cladding, signage, and structural components, providing weather resistance, support, and aesthetic appeal.

- Aerospace: Utilized in aircraft interiors, structural elements, and tooling, where stringent requirements for strength, weight, and safety are paramount.

- Automotive: Employed in body panels, interior trim, and protective components, offering durability and impact resistance.

- Chemical Processing: Implemented in tanks, linings, and equipment housings, providing resistance to corrosive chemicals and extreme temperatures.

- Food Processing: Used for sanitary surfaces, equipment components, and packaging, ensuring hygiene and compliance with food safety standards.

- Electronics: Found in enclosures, insulation, and circuit board substrates, providing electrical insulation and physical protection.

Choosing the Right Industrial Grade Sheet:

Selecting the appropriate industrial grade sheet is crucial for ensuring optimal performance and longevity. Key factors to consider include:

- Application Requirements: Understanding the specific demands of the application, such as load-bearing capacity, chemical exposure, temperature range, and wear resistance, is essential.

- Material Properties: Each material offers a unique set of properties, so it’s important to choose one that aligns with the application’s requirements. For example, stainless steel is ideal for corrosive environments, while polycarbonate offers high impact resistance.

- Sheet Thickness and Size: The thickness and size of the sheet should be appropriate for the application’s dimensions and structural needs.

- Surface Finish: Different surface finishes can provide varying levels of aesthetics, texture, and resistance to scratches and wear.

- Cost Considerations: While durability and performance are paramount, budget constraints should also be considered when selecting an industrial grade sheet.

The Future of Industrial Grade Sheets:

As technology advances, so too does the development of industrial grade sheets. We can expect to see ongoing innovation in:

- Material Science: The creation of new materials with enhanced properties, such as improved strength-to-weight ratios, self-healing capabilities, and increased resistance to extreme conditions.

- Sustainable Manufacturing: The adoption of eco-friendly manufacturing processes and the use of recycled materials to reduce environmental impact.

- Smart Materials: The integration of sensors and other technologies into industrial grade sheets to monitor performance, detect damage, and provide real-time data.

In conclusion, industrial grade sheets are the unsung heroes of modern industry, providing the essential foundation for countless applications. Their durability, versatility, and adherence to stringent standards ensure reliable performance and contribute to the safety and efficiency of operations across a wide range of sectors. As technology continues to evolve, we can expect even greater innovation in this critical area, further expanding the possibilities for industrial applications.

Reviews

There are no reviews yet.