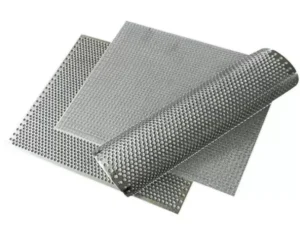

Description

When the Heat is On: Understanding High Temperature Wire Mesh

In demanding environments where extreme temperatures are the norm, ordinary materials crumble and fail. This is where high temperature wire mesh steps in, offering a robust and reliable solution for a wide array of applications. From aerospace engineering to industrial processing, this specialized mesh is engineered to withstand intense heat and maintain its structural integrity.

What is High Temperature Wire Mesh?

Simply put, high temperature wire mesh is woven wire cloth made from alloys specifically chosen for their ability to resist degradation at elevated temperatures. Unlike standard steel mesh, which can soften, deform, and corrode under intense heat, high temperature materials retain their strength, shape, and corrosion resistance.

The Key to Its Resilience: Material Matters

The selection of the right alloy is critical. Common materials used in high temperature wire mesh include:

- Stainless Steel Alloys: Notably 304, 316, and 310 stainless steel, all offering good corrosion resistance and heat resistance up to varying degrees. 310, with its higher chromium and nickel content, boasts superior heat resistance compared to 304 and 316.

- Nickel Alloys: Alloys like Inconel, Hastelloy, and Monel exhibit exceptional high-temperature strength, oxidation resistance, and creep resistance, making them ideal for the most demanding applications. These are often used when temperatures exceed the capabilities of stainless steel.

- Refractory Metals: For extreme temperature applications exceeding 1000°C, refractory metals like tungsten, molybdenum, and tantalum are used. These materials are incredibly strong and maintain their properties at very high temperatures, but often require protective atmospheres to prevent oxidation.

The chosen material dictates the maximum temperature the mesh can withstand, its resistance to oxidation and corrosion, its strength, and its cost.

Applications Across Industries:

The versatile properties of high temperature wire mesh make it an indispensable component in numerous industries:

- Aerospace: Used in engine components, heat shields, and filtration systems where exposure to extreme heat is unavoidable.

- Industrial Furnaces: Essential for furnace belts, heat treating baskets, and other components that directly interface with high-temperature environments.

- Petrochemical: Employed in catalytic converters, filtration systems, and other applications requiring resistance to both high temperatures and corrosive chemicals.

- Power Generation: Used in boiler systems, exhaust systems, and other power generation equipment where heat resistance is paramount.

- Food Processing: Utilized in ovens, fryers, and other high-temperature food processing equipment.

- Cement Production: Vital in kiln components that are constantly exposed to intense heat during cement production.

Benefits Beyond Heat Resistance:

Beyond its primary function of withstanding high temperatures, high temperature wire mesh offers several additional benefits:

- Corrosion Resistance: Many high-temperature alloys also exhibit excellent resistance to corrosion, ensuring longevity and reliability in harsh environments.

- Strength and Durability: Retains its structural integrity under stress, even at elevated temperatures.

- Versatility: Can be woven into various mesh sizes and patterns to suit specific filtration, separation, or support requirements.

- Long Lifespan: Properly selected and maintained, high temperature wire mesh can provide years of reliable service.

Choosing the Right Mesh:

Selecting the appropriate high temperature wire mesh requires careful consideration of several factors:

- Maximum Operating Temperature: Determine the highest temperature the mesh will be exposed to.

- Chemical Exposure: Identify any corrosive chemicals the mesh will encounter.

- Load Requirements: Consider the weight and stress the mesh will need to support.

- Mesh Size and Opening: Choose the appropriate mesh size for the intended application, whether it’s filtration, separation, or simply structural support.

- Budget: Different alloys and mesh configurations come with varying costs.

Consulting with a reputable wire mesh supplier is crucial for selecting the optimal material and configuration for your specific application. They can provide expert guidance and ensure that you choose a mesh that will perform reliably and consistently in even the most demanding high-temperature environments.

Conclusion:

High temperature wire mesh is a critical component in countless industries, enabling processes and applications that would be impossible with ordinary materials. By understanding the properties, applications, and selection criteria for this specialized mesh, engineers and manufacturers can leverage its unique capabilities to achieve optimal performance in the face of extreme heat. When the heat is on, high temperature wire mesh stands strong, delivering the reliability and durability needed to keep critical operations running smoothly.

Reviews

There are no reviews yet.