Description

Beyond the Heat Barrier: Unlocking Potential with High-Temperature Polyimides

In the relentless pursuit of performance, modern industries constantly push the boundaries of material science. From the searing heat of jet engines to the intricate demands of advanced electronics, conventional plastics often fail, literally melting under pressure. This is where high-temperature polyimides emerge as unsung heroes, providing an exceptional blend of thermal stability, mechanical strength, and chemical resistance that enables groundbreaking innovation.

What are Polyimides?

Polyimides (PIs) are a class of high-performance polymers characterized by the presence of imide rings in their molecular backbone. This unique chemical structure, typically formed through the condensation reaction of diamines and dianhydrides, grants them remarkable properties. While all polyimides possess good thermal stability, “high-temperature” polyimides are specifically engineered variants designed to withstand extreme and prolonged exposure to elevated temperatures, often exceeding 250°C (482°F) and in some cases, pushing past 400°C (752°F).

The Secret to Their Unyielding Nature

The exceptional thermal and mechanical properties of high-temperature polyimides stem directly from their molecular architecture:

- Rigid Cyclic Structures: The presence of aromatic (ring-like) structures within the polymer chain, combined with the stiff imide rings, creates a highly rigid and stable backbone. This intrinsic stiffness resists molecular motion, preventing softening and degradation at high temperatures.

- Strong Intermolecular Forces: Hydrogen bonding and strong dipole-dipole interactions between polymer chains contribute to high cohesive energy, further enhancing their thermal stability and mechanical integrity.

- High Glass Transition Temperature (Tg): Tg is the temperature at which an amorphous polymer transitions from a hard, glassy state to a softer, more rubbery state. High-temperature polyimides boast exceptionally high Tgs, meaning they retain their mechanical properties even when exposed to significant heat.

- Thermo-oxidative Stability: Their chemical structure also makes them highly resistant to degradation by oxygen at elevated temperatures, a common failure mechanism for many other polymers.

Key Properties that Define High-Temperature Polyimides:

- Exceptional Thermal Stability: Unmatched long-term service temperatures, often above 250°C (482°F), with short-term resistance much higher.

- Outstanding Mechanical Strength: High tensile strength, stiffness, and creep resistance, maintaining structural integrity under load even at elevated temperatures.

- Excellent Chemical Resistance: Withstand a wide range of organic solvents, fuels, oils, and many acids and bases.

- Superior Electrical Properties: High dielectric strength, low dielectric constant, and low dissipation factor, making them excellent insulators and ideal for demanding electronic applications.

- Low Coefficient of Thermal Expansion (CTE): Dimensionally stable across a broad temperature range, crucial for precision applications where thermal cycling occurs.

- Radiation Resistance: Good resistance to various forms of radiation, including UV, X-ray, and gamma radiation, vital for aerospace and medical applications.

- Low Outgassing: Minimizes the release of volatile compounds in vacuum environments, essential for space and semiconductor manufacturing.

Versatile Forms for Diverse Applications:

High-temperature polyimides are available in various forms, each tailored for specific uses:

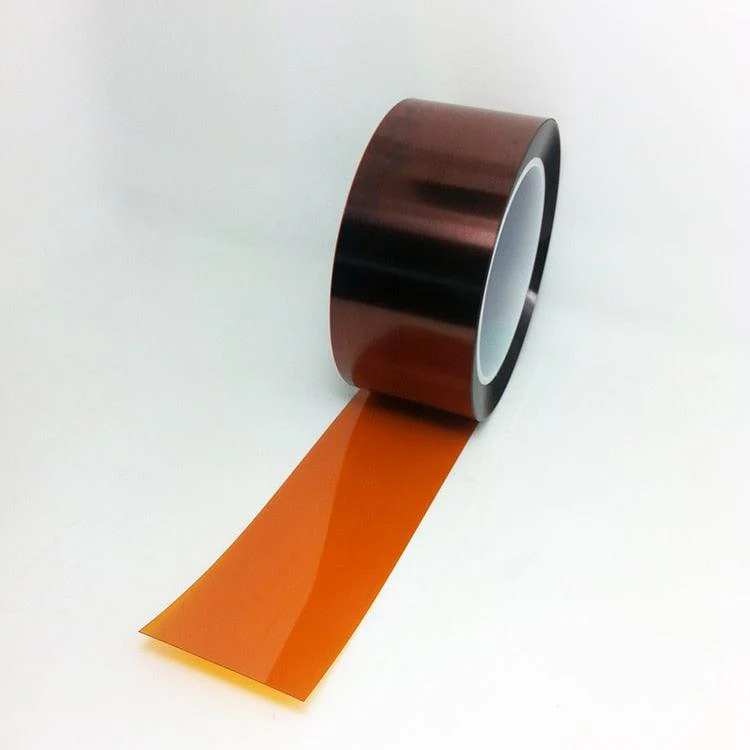

- Films: Thin, flexible sheets (e.g., Kapton®) used for electrical insulation, flexible printed circuits, and thermal blankets.

- Resins: Liquid or solid forms used for molding, casting, and as matrices for high-performance composites.

- Fibers: Used in high-temperature textiles, filtration systems, and as reinforcement in composites.

- Coatings: Applied to surfaces for corrosion protection, electrical insulation, and wear resistance in harsh environments.

- Foams: Lightweight, high-temperature insulation materials.

Revolutionizing Industries: Applications of High-Temperature Polyimides

The unique properties of high-temperature polyimides make them indispensable across a multitude of cutting-edge industries:

- Aerospace & Defense: Engine components (ducts, seals, nozzles), lightweight structural parts, thermal blankets for spacecraft, radomes, insulation for wiring, and missile components. Their strength-to-weight ratio and ability to withstand extreme temperatures are critical.

- Electronics: Flexible printed circuit boards (PCBs), insulation layers in multi-chip modules, wire and cable insulation, semiconductor packaging, and high-temperature electrical connectors. They enable miniaturization and reliability in high-density electronics.

- Automotive: Under-the-hood components exposed to high temperatures (e.g., transmission parts, sensors, seals, bushings), lightweight structural components, and high-performance brake systems.

- Industrial: Bearings, gears, seals, and other wear parts operating in high-temperature or chemically aggressive environments, components for hot fluid handling, and high-temperature filtration media.

- Medical: Sterilizable components, surgical tools, and specific implantable devices where high-temperature sterilization and chemical inertness are required.

- Energy: Components in oil and gas exploration (downhole tools), and parts for high-temperature fuel cells.

Challenges and the Future Outlook:

Despite their impressive capabilities, high-temperature polyimides come with certain challenges: primarily their higher cost compared to conventional polymers and the difficulty of processing due to their high melting points and rigidity. This often requires specialized equipment and processing techniques.

However, research continues to push the boundaries. Innovations are focusing on:

- Easier Processability: Developing new formulations that can be processed at lower temperatures or through additive manufacturing (3D printing) techniques.

- Enhanced Performance: Creating polyimides with even higher temperature resistance, improved mechanical properties, or tailored electrical characteristics.

- Cost Reduction: Exploring new synthesis routes and raw materials to make these materials more economically viable for broader applications.

- Sustainability: Investigating recyclable or bio-based polyimide precursors.

Conclusion:

High-temperature polyimides are far more than just “heat-resistant plastics.” They are a cornerstone of modern engineering, enabling designs and functionalities that would be impossible with lesser materials. As industries continue to demand higher performance in increasingly extreme environments, these remarkable polymers will remain at the forefront, silently empowering the next generation of technological breakthroughs, pushing the limits of what’s possible, one degree at a time.

Reviews

There are no reviews yet.