Description

Graphene-Based Adsorbents: A Revolution in Capture and Clean-Up Technology

Graphene, a single-layer sheet of carbon atoms arranged in a hexagonal lattice, has captivated scientists and engineers with its exceptional properties. Beyond its remarkable strength, electrical conductivity, and thermal stability, graphene holds immense promise as an advanced adsorbent material. Its high surface area, tunable surface chemistry, and ease of modification are driving a revolution in various fields, from environmental remediation to gas storage and beyond.

What Makes Graphene a Great Adsorbent?

Adsorption involves the adhesion of atoms, ions, or molecules from a gas, liquid, or dissolved solid to a surface. Graphene’s suitability as an adsorbent stems from several key features:

- High Surface Area: The two-dimensional nature of graphene provides an exceptionally large surface area for interaction with target molecules. This maximizes the potential for adsorption, enabling efficient removal of contaminants or storage of gases.

- Tunable Surface Chemistry: The chemical properties of graphene can be readily modified through functionalization. Introducing specific chemical groups allows for selective interaction with particular target molecules, enhancing adsorption efficiency and specificity. This includes adding oxygen-containing groups, polymers, or even metal nanoparticles.

- Mechanical Strength and Stability: Graphene’s inherent strength and stability ensure its integrity under various operating conditions, making it a durable and reliable adsorbent material.

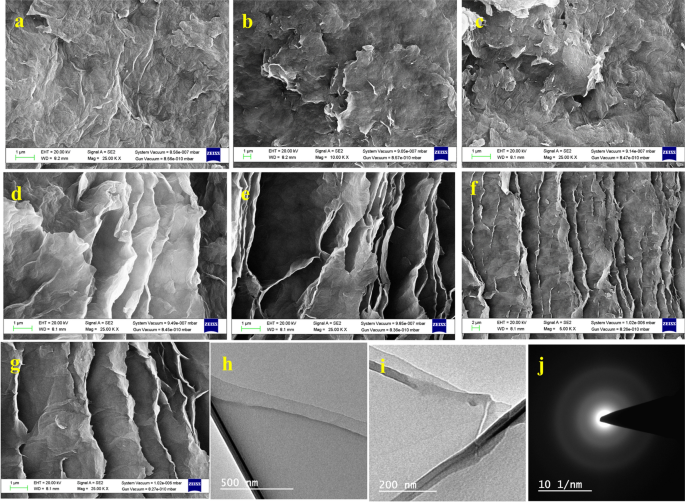

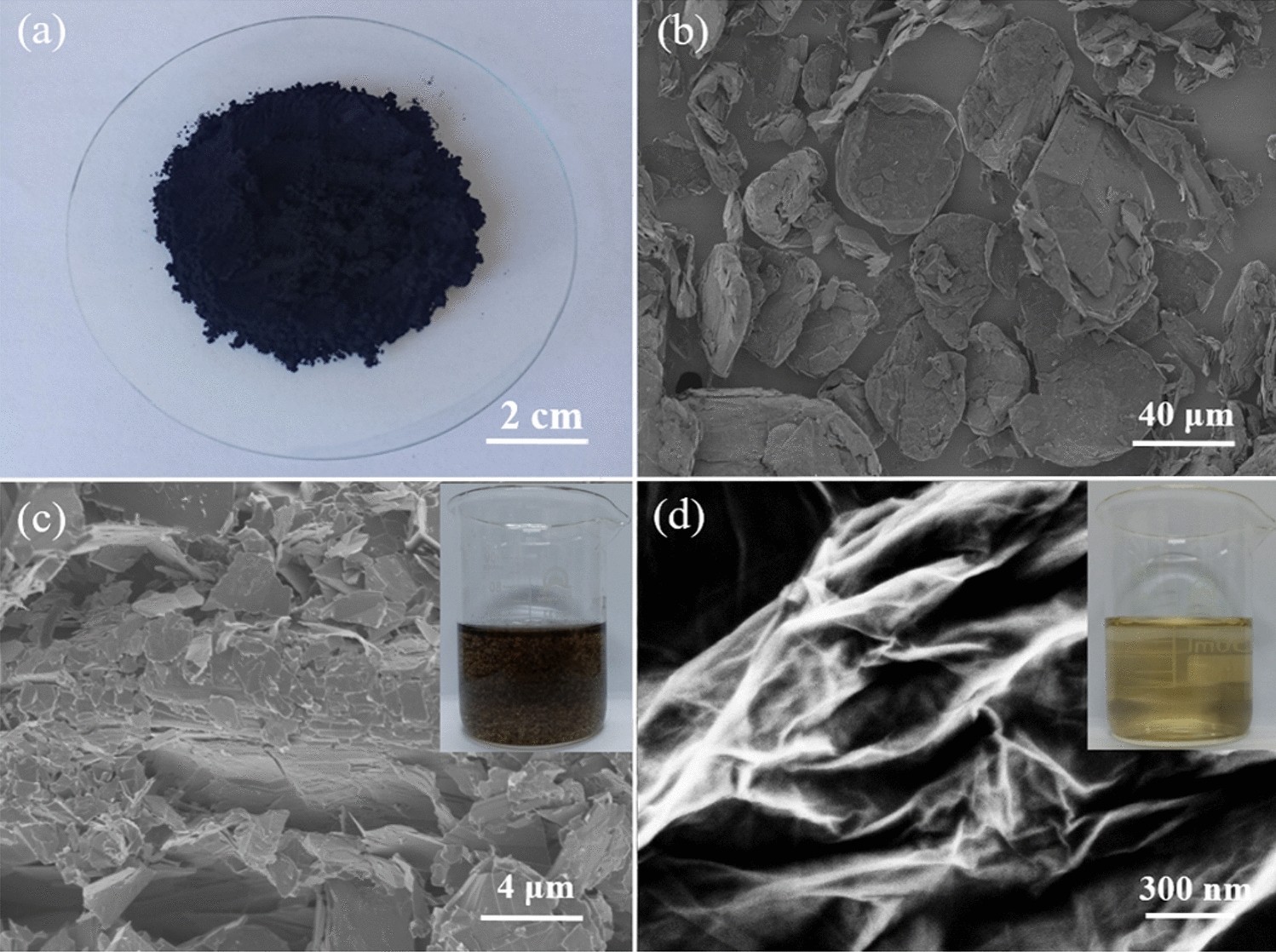

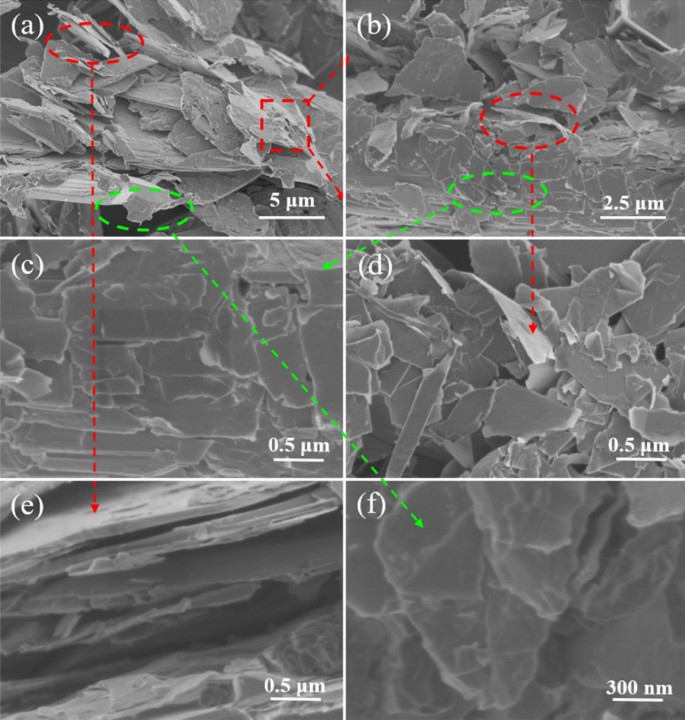

- Ease of Synthesis and Processing: While pristine graphene can be challenging to produce on a large scale, various methods like chemical vapor deposition (CVD) and reduction of graphene oxide (rGO) allow for the creation of graphene-based materials in a cost-effective manner. These methods also enable the formation of graphene composites with enhanced properties.

Applications of Graphene-Based Adsorbents:

The unique properties of graphene-based materials are being leveraged in a wide range of applications, including:

- Water Purification: Graphene adsorbents can effectively remove pollutants like heavy metals, organic dyes, pharmaceuticals, and bacteria from contaminated water. Its high surface area and functionalizability allow for targeted removal of specific contaminants, offering a highly efficient and eco-friendly alternative to traditional methods.

- Air Purification: Removing volatile organic compounds (VOCs), greenhouse gases like CO2, and pollutants like NOx and SOx from the air is crucial for mitigating climate change and improving air quality. Graphene-based materials are being explored for their ability to selectively adsorb these gases, contributing to cleaner and healthier environments.

- Gas Storage: Hydrogen, methane, and other gases can be efficiently stored on graphene surfaces, making it a promising material for fuel storage applications. The high surface area and tunable pore structure of graphene enable high gas storage capacities at ambient temperatures and pressures.

- Chemical Sensing: Graphene’s sensitivity to changes in its environment makes it ideal for developing highly sensitive chemical sensors. By modifying the graphene surface, it can be designed to selectively bind to specific target molecules, allowing for real-time detection and monitoring.

- Heavy Metal Removal: Graphene oxide (GO) and reduced graphene oxide (rGO) are particularly effective in removing heavy metals like lead, mercury, and arsenic from water sources. Their oxygen-containing functional groups offer strong binding sites for these metals, facilitating their removal from contaminated water.

- Oil Spill Remediation: Graphene-based aerogels and sponges exhibit excellent oil absorption capacity and selectivity, making them valuable tools for cleaning up oil spills. These materials can effectively absorb oil from water surfaces, preventing further environmental damage.

Challenges and Future Directions:

Despite the immense potential of graphene-based adsorbents, several challenges need to be addressed to realize their full potential:

- Large-Scale Production: Cost-effective and scalable methods for producing high-quality graphene materials are crucial for widespread adoption.

- Material Handling and Stability: Graphene nanomaterials can agglomerate, reducing their effective surface area. Developing strategies to prevent agglomeration and improve dispersion is essential.

- Regeneration and Reusability: Developing efficient methods for regenerating and reusing graphene adsorbents is crucial for ensuring their long-term sustainability and economic viability.

- Environmental Impact: A thorough assessment of the environmental impact of graphene-based materials throughout their lifecycle is necessary to ensure they are truly sustainable solutions.

Conclusion:

Graphene-based adsorbents are poised to revolutionize various fields by offering superior performance, efficiency, and sustainability. Ongoing research and development efforts are focused on addressing the existing challenges and exploring new applications for these remarkable materials. As production costs decrease and performance improves, graphene-based adsorbents will undoubtedly play a significant role in creating a cleaner, safer, and more sustainable future. Their ability to selectively capture and remove contaminants, store energy, and sense their environment makes them an invaluable tool in addressing some of the world’s most pressing challenges.

Reviews

There are no reviews yet.