Description

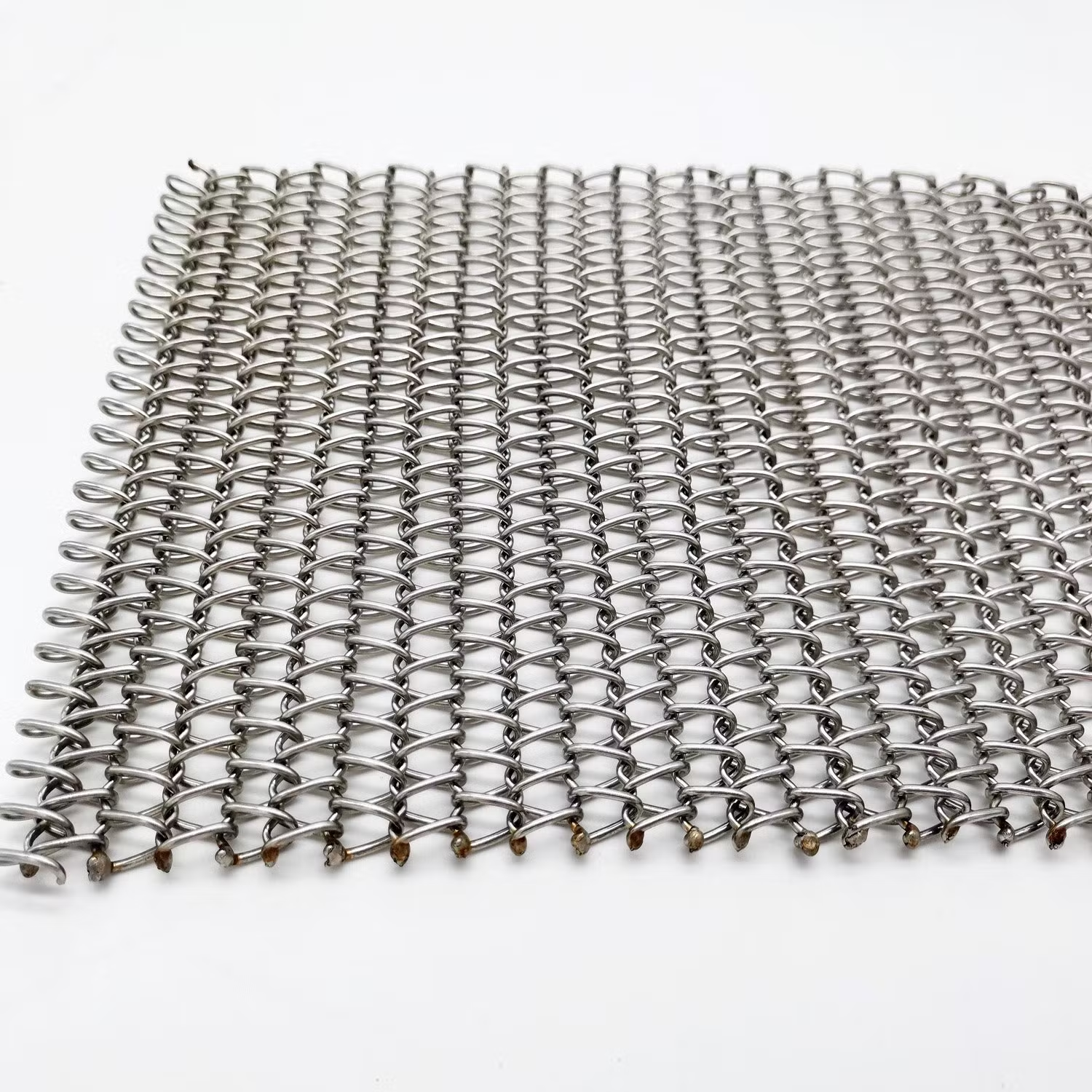

Food Grade Wire Mesh: Ensuring Safety and Efficiency in Food Processing

In the intricate world of food processing, where hygiene and safety are paramount, choosing the right materials is crucial. Food grade wire mesh, a specialized type of woven wire fabric, plays a vital and often unseen role in ensuring the quality and safety of the food we consume. From straining sauces to supporting conveyor belts, its applications are diverse and its importance undeniable.

What is Food Grade Wire Mesh?

Food grade wire mesh isn’t just any wire mesh. It’s specifically manufactured using materials and processes that meet stringent standards for food contact. This means it’s made from materials that are:

- Non-toxic: Will not leach harmful chemicals into food.

- Corrosion-resistant: Can withstand the harsh conditions of food processing, including exposure to acids, alkalis, and high temperatures.

- Cleanable and Sanitizable: Easy to clean and disinfect, preventing the growth of bacteria and other contaminants.

- Durable: Can withstand repetitive use and varying weights and temperatures without breaking down or degrading.

Common Materials Used:

The most common material used in food grade wire mesh is stainless steel. Specifically, 304 and 316 stainless steel are preferred due to their excellent corrosion resistance, strength, and ease of cleaning. Other materials, such as certain grades of nickel alloys, may be used for specific applications with specialized requirements.

Key Applications in Food Processing:

Food grade wire mesh finds applications throughout the entire food processing chain, including:

- Filtration and Straining: Removing unwanted particles from liquids like sauces, juices, and oils. Different mesh sizes allow for precise control over particle size.

- Drying and Dehydration: Providing a stable and sanitary surface for drying fruits, vegetables, herbs, and other ingredients.

- Sifting and Grading: Separating food ingredients by size, ensuring uniformity and consistency.

- Conveyor Belts: Transporting food products through various stages of processing, such as washing, cooking, and packaging.

- Cooking and Baking: Used in ovens, grills, and smokers to support food products while allowing for even heat distribution.

- Equipment Guards and Screens: Protecting equipment and workers from hazards while maintaining clean and sanitary conditions.

- Freezing and Cooling: Providing support for foods during freezing and cooling processes, ensuring even temperature distribution.

Benefits of Using Food Grade Wire Mesh:

The advantages of using food grade wire mesh in food processing are numerous:

- Ensured Food Safety: Minimizes the risk of contamination and ensures compliance with food safety regulations.

- Improved Product Quality: Contributes to consistent particle size, uniform drying, and even cooking.

- Increased Efficiency: Optimizes processes by facilitating faster filtration, drying, and sifting.

- Reduced Waste: Prevents product loss through efficient filtration and sifting.

- Extended Equipment Lifespan: Resistant to corrosion and wear, reducing the need for frequent replacements.

- Compliance with Regulations: Meets the requirements of food safety agencies like the FDA, ensuring regulatory compliance.

Choosing the Right Food Grade Wire Mesh:

Selecting the appropriate food grade wire mesh for a specific application requires careful consideration of several factors:

- Material: Choose the right grade of stainless steel or other approved material based on the specific food product and processing conditions.

- Mesh Size: Select the appropriate mesh size to achieve the desired level of filtration, sifting, or drying.

- Wire Diameter: Consider the strength and durability requirements of the application when choosing the wire diameter.

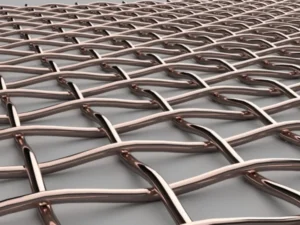

- Weave Type: Choose the appropriate weave pattern based on the required flow rate, strength, and stability.

- Surface Finish: Ensure the surface finish is smooth and free from imperfections to facilitate cleaning and prevent bacterial growth.

Conclusion:

Food grade wire mesh is an indispensable component of modern food processing. By providing a safe, durable, and efficient solution for a wide range of applications, it plays a crucial role in ensuring the safety and quality of the food we consume. Choosing the right food grade wire mesh is an investment in food safety, product quality, and operational efficiency. As food safety regulations become stricter and consumer expectations rise, the importance of food grade wire mesh will only continue to grow.

Reviews

There are no reviews yet.