Description

Dutch Weave Wire Mesh: Strength and Precision in Filtration and Beyond

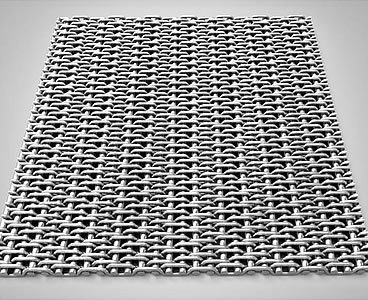

Dutch weave wire mesh, also known as filter cloth, stands apart from its plain and twill weave counterparts due to its unique construction and superior filtration capabilities. Its tightly packed wires and distinct weave pattern offer enhanced strength, finer filtration, and excellent resistance to deformation, making it an ideal solution for demanding applications across various industries.

What is Dutch Weave Wire Mesh?

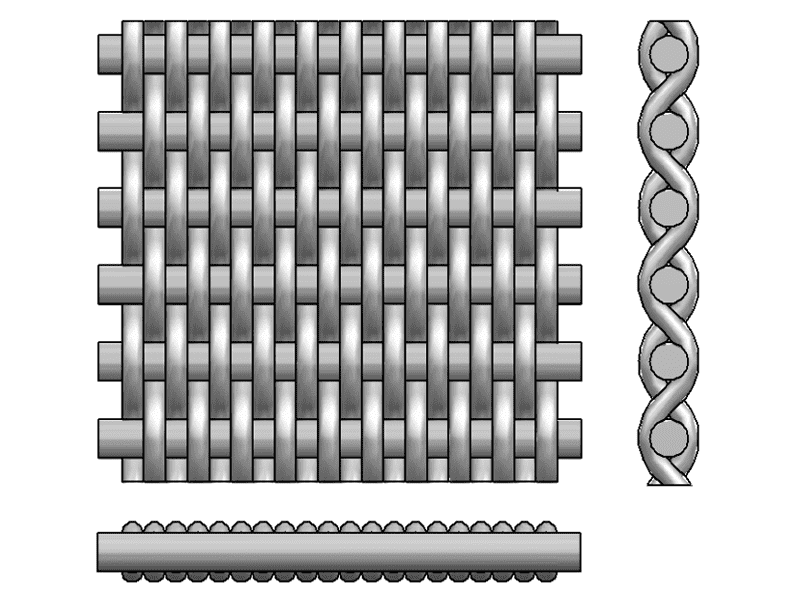

Unlike plain and twill weaves where warp (longitudinal) and weft (transverse) wires are typically of comparable diameter, Dutch weave distinguishes itself through its use of significantly thicker warp wires and finer weft wires. The heavier warp wires provide the mesh with exceptional strength and stability. The closely spaced, extremely fine weft wires, woven tightly together, create a smaller, more complex pore structure ideal for intricate filtration.

The Weave Patterns: Plain Dutch Weave vs. Twilled Dutch Weave

While the general principle remains the same, Dutch weave wire mesh comes in two primary variations:

- Plain Dutch Weave: In this pattern, each weft wire passes over one warp wire and under the next, resulting in a very fine and dense structure. It’s known for its excellent filtration capabilities and high dirt-holding capacity.

- Twilled Dutch Weave: This pattern, similar to a twill weave, allows for even finer filtration. Weft wires pass over two or more warp wires before going under two or more, creating diagonal ribs on the surface. This structure offers improved strength, stability and the ability to filter particles of even smaller sizes.

Key Advantages of Dutch Weave Wire Mesh:

- Superior Filtration: The primary advantage lies in its ability to filter extremely fine particles. The tightly packed weft wires create a tortuous path for fluids, trapping microscopic particles that would pass through other wire mesh types.

- High Strength and Stability: The use of thicker warp wires provides exceptional tensile strength and resistance to deformation under pressure. This makes it suitable for high-pressure and high-temperature environments.

- High Dirt-Holding Capacity: The intricate weave allows for a larger surface area for particle capture, resulting in a higher dirt-holding capacity and longer filter life.

- Excellent Flow Rate: Despite the fine filtration capabilities, carefully designed Dutch weave can maintain a surprisingly good flow rate, minimizing pressure drop.

- Customizable Pore Size: By adjusting the diameter and spacing of the warp and weft wires, manufacturers can tailor the pore size to meet specific filtration requirements.

Applications Across Industries:

The unique properties of Dutch weave wire mesh make it a crucial component in a wide range of applications, including:

- Aerospace: Filtering hydraulic fluids, fuel, and lubricants to ensure proper engine and system performance.

- Chemical Processing: Separating solids from liquids in chemical reactions, removing impurities from process streams, and filtering catalysts.

- Food and Beverage: Filtering oils, juices, syrups, and other food products to remove contaminants and improve quality.

- Pharmaceutical: Filtering pharmaceutical ingredients and products to meet stringent purity standards.

- Petroleum Refining: Filtering crude oil and petroleum products to remove impurities and protect downstream equipment.

- Water Treatment: Removing suspended solids and other contaminants from water supplies.

- Plastics Industry: Filtering molten polymers to remove contaminants and improve the quality of finished plastic products.

- Automotive: Filtering fuel, oil, and air in automotive engines.

Choosing the Right Dutch Weave Mesh:

Selecting the correct Dutch weave wire mesh for a specific application requires careful consideration of several factors, including:

- Filtration Requirements: The desired particle size to be filtered.

- Operating Conditions: The temperature, pressure, and chemical environment.

- Flow Rate Requirements: The desired flow rate of the filtered fluid.

- Material Compatibility: The compatibility of the mesh material with the fluid being filtered.

- Mesh Size and Opening: The number of wires per inch and the resulting pore size.

Conclusion:

Dutch weave wire mesh represents a sophisticated solution for applications demanding precise and reliable filtration. Its unique construction, superior strength, and customizable pore size have made it a cornerstone in numerous industries, enabling manufacturers to achieve higher levels of purity, efficiency, and performance. As technology continues to advance, Dutch weave wire mesh will undoubtedly remain a critical component in addressing the ever-evolving challenges of filtration and separation.

Reviews

There are no reviews yet.