Description

The Unsung Heroes Beneath Our Feet: Understanding Drill Pipes

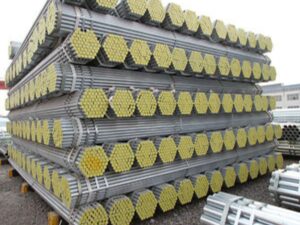

Drill pipes, often overlooked, are the backbone of the oil and gas industry, playing a critical role in accessing the earth’s resources. They are the unsung heroes working tirelessly beneath our feet, enabling the extraction of hydrocarbons and other valuable materials from deep underground. This article delves into the world of drill pipes, exploring their function, construction, different types, and the challenges they face in the harsh environments they operate in.

What are Drill Pipes and Why are They Important?

Drill pipes are long, hollow, thick-walled tubes that form the drill string in rotary drilling. This drill string is the conduit through which drilling fluid is pumped down the wellbore and back, crucial for:

- Rotation: Transferring rotational power from the drilling rig at the surface to the drill bit at the bottom of the well. This allows the bit to grind and cut through rock formations.

- Fluid Circulation: Delivering drilling mud (a specialized fluid) to the drill bit, cooling it, lubricating it, and carrying rock cuttings back to the surface.

- Weight on Bit: Allowing the driller to apply controlled weight to the drill bit, optimizing its cutting efficiency.

- Wellbore Integrity: Contributing to the overall stability of the wellbore and preventing collapse.

Without drill pipes, deep drilling would be impossible. They are essential for accessing oil, natural gas, geothermal energy, and even conducting geological surveys deep within the Earth.

Construction and Materials:

Drill pipes are manufactured to strict industry standards, ensuring they can withstand the immense pressures, torques, and corrosive environments they encounter. Key aspects of their construction include:

- Steel Alloys: Typically made from high-strength steel alloys, such as carbon steel or alloy steel, chosen for their yield strength, tensile strength, and resistance to corrosion.

- Threading: Possess robust threaded connections (tool joints) at each end, allowing them to be easily connected and disconnected during drilling operations. These threads are often hardened and treated to prevent wear and tear.

- Wall Thickness: Varying wall thicknesses, depending on the depth and pressure conditions, to ensure structural integrity.

- Coating and Treatment: Often coated with protective materials to resist corrosion, erosion, and other forms of degradation.

Types of Drill Pipes:

Different drilling scenarios require specialized drill pipes, including:

- Standard Drill Pipe: The most common type, used for general drilling applications.

- Heavy-Weight Drill Pipe (HWDP): Designed with a thicker wall section near the tool joints, providing additional weight and stiffness in the lower part of the drill string. This helps to reduce stress concentrations and improve drill string stability.

- Spiral Drill Pipe: Features a helical groove pattern on the outer surface, improving mud flow and reducing differential sticking, a common problem in certain formations.

- Non-Magnetic Drill Pipe: Used in directional drilling where accurate magnetic surveying is crucial. These pipes are made from non-magnetic alloys to avoid interference with the compass readings.

Challenges and Considerations:

Drill pipes operate in extraordinarily demanding environments, facing numerous challenges:

- High Pressure and Temperature: Deep wells can experience extremely high pressures and temperatures, requiring pipes with exceptional strength and heat resistance.

- Corrosive Fluids: Drilling mud and formation fluids can be highly corrosive, potentially leading to rapid pipe degradation and failure.

- Fatigue and Wear: Constant rotation, vibration, and contact with abrasive rocks can cause fatigue and wear, weakening the pipe over time.

- Hydrogen Embrittlement: Certain chemicals in the drilling environment can lead to hydrogen embrittlement, making the steel more susceptible to cracking.

To mitigate these challenges, rigorous inspection and maintenance programs are crucial. These programs involve:

- Visual Inspection: Regularly checking for signs of wear, corrosion, and damage.

- Non-Destructive Testing (NDT): Utilizing techniques like ultrasonic testing and magnetic particle inspection to detect hidden flaws.

- Thread Inspection: Ensuring proper thread integrity to prevent connection failures.

- Drift Testing: Verifying the internal diameter of the pipe to ensure it is not obstructed.

The Future of Drill Pipes:

As drilling technology advances and wells become deeper and more complex, the demand for high-performance drill pipes will continue to grow. Ongoing research and development efforts are focused on:

- Developing Stronger Materials: Exploring new alloys and composite materials to improve strength, corrosion resistance, and weight reduction.

- Smart Drill Pipes: Integrating sensors and communication technologies into drill pipes to monitor performance in real-time and detect potential problems before they escalate.

- Improved Coatings: Developing more durable and environmentally friendly coatings to protect against corrosion and erosion.

In conclusion, drill pipes are a vital component of the oil and gas industry and other drilling operations. Understanding their function, construction, and the challenges they face is crucial for optimizing drilling performance, ensuring wellbore integrity, and ultimately, accessing the resources that power our modern world. As drilling technology evolves, the continuous development and refinement of drill pipe design and materials will remain essential for unlocking the Earth’s potential.

Reviews

There are no reviews yet.