Description

Crimped Wire Mesh: Strength, Versatility, and a Woven Edge

Crimped wire mesh, also known as woven wire mesh, is a versatile and robust material used in a wide array of applications. Unlike welded wire mesh, which is fused at the intersections, crimped wire mesh relies on a precise weaving process where wires are pre-crimped, then interwoven to create a strong, interlocking structure. This crimping technique imparts unique characteristics to the mesh, making it a valuable choice for projects demanding durability, aesthetic appeal, and specific filtration or separation capabilities.

The Art of the Crimp: Understanding the Weaving Process

The defining feature of crimped wire mesh is the crimping itself. Before the wires are even interwoven, they undergo a process of being crimped, or pre-bent, at regular intervals. These crimps provide the key to the mesh’s strength and stability. There are several common crimp types, each offering unique performance characteristics:

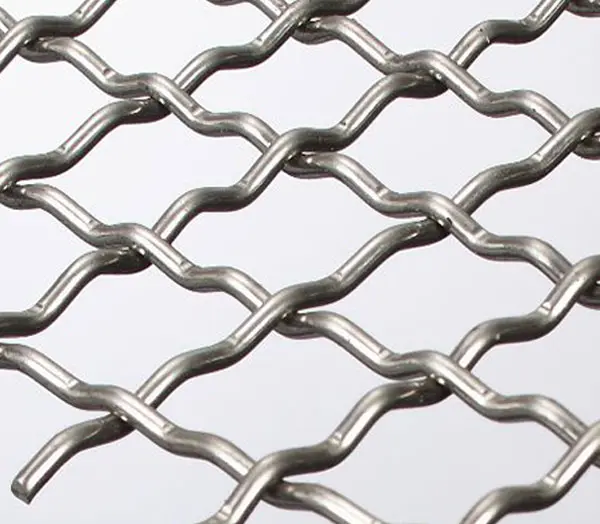

- Plain Crimp: The simplest and most common type, featuring alternating crimps along the wire. This provides a good balance of strength and flexibility.

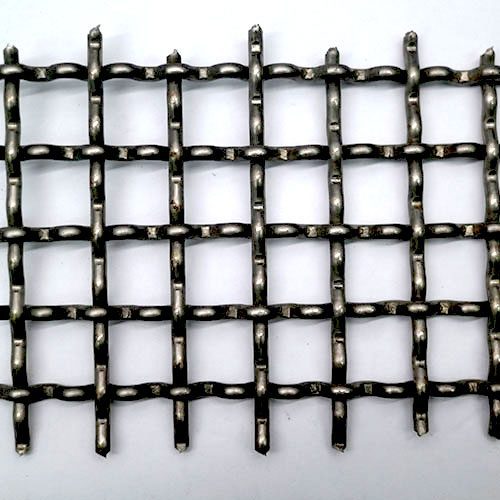

- Lock Crimp: A more robust variation where the crimps lock together at the intersections, offering increased stability and resistance to deformation.

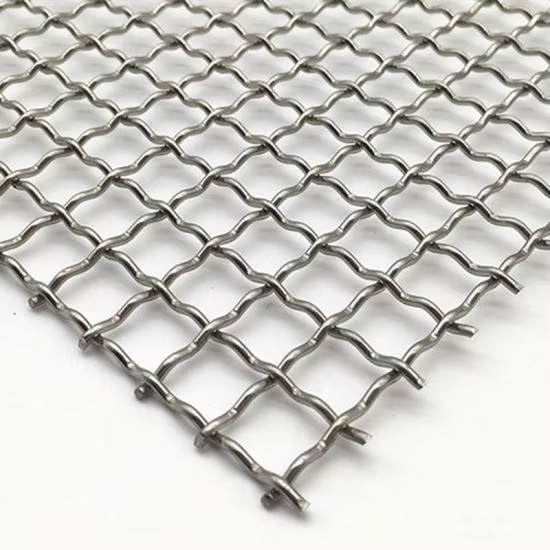

- Intermediate Crimp: Features additional crimps between intersections, further increasing the mesh’s rigidity and load-bearing capacity.

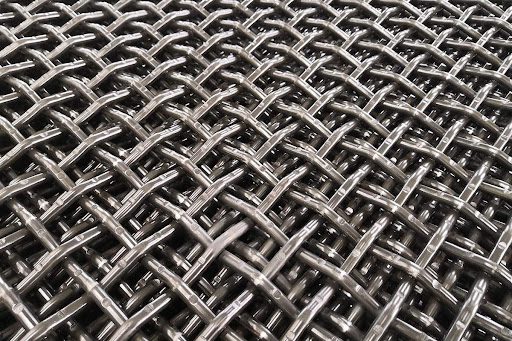

- Flat Top Crimp: Creates a smooth, level surface on one side of the mesh, making it ideal for applications where a flat surface is crucial, such as screens and architectural panels.

The choice of crimp type depends entirely on the specific application and the desired performance characteristics.

Key Benefits of Crimped Wire Mesh:

- Strength and Durability: The interlocking crimps distribute stress evenly across the mesh, resulting in exceptional strength and resistance to impact. This makes crimped wire mesh suitable for demanding environments.

- Dimensional Stability: Pre-crimping ensures that the mesh maintains its shape and dimensions under load, preventing stretching or sagging.

- Aesthetic Appeal: The woven pattern of crimped wire mesh provides a visually appealing texture, making it popular for architectural applications and decorative elements.

- Versatility: Crimped wire mesh can be manufactured from a wide range of materials, including stainless steel, carbon steel, aluminum, copper, and brass, allowing for customization to suit specific environmental and performance requirements.

- Customization: Manufacturers can tailor the wire diameter, aperture size (the distance between wires), and crimp type to create a mesh optimized for specific applications.

Diverse Applications Across Industries:

The versatility of crimped wire mesh leads to its widespread use across various industries:

- Architecture and Design: Facades, railings, partitions, sunshades, and decorative panels leverage the aesthetic appeal and durability of crimped wire mesh.

- Mining and Quarrying: Screening and sizing of aggregates, minerals, and other materials.

- Agriculture: Livestock enclosures, animal cages, and agricultural screens.

- Industrial Filtration: Fluid and air filtration in various industrial processes.

- Food Processing: Conveyor belts, drying racks, and sieving equipment.

- Security: Security screens, perimeter fencing, and safety barriers.

- Construction: Reinforcement mesh for concrete structures and plaster backing.

Choosing the Right Crimped Wire Mesh:

Selecting the appropriate crimped wire mesh for a specific application requires careful consideration of several factors:

- Material: Choose a material that is compatible with the environment and the materials the mesh will be in contact with. Stainless steel is ideal for corrosive environments, while carbon steel offers a cost-effective solution for less demanding applications.

- Wire Diameter: Thicker wires provide greater strength and durability but can also decrease the open area of the mesh.

- Aperture Size: The size of the opening between the wires affects the mesh’s filtration capabilities, ventilation, and visibility.

- Crimp Type: Select the crimp type that best suits the load-bearing requirements and desired aesthetic.

- Mesh Size: Consider the overall dimensions of the mesh panel and any necessary fabrication requirements.

Conclusion:

Crimped wire mesh stands out as a durable, versatile, and aesthetically pleasing material for a wide range of applications. Its unique woven structure, achieved through precise crimping techniques, provides exceptional strength, dimensional stability, and customization options. Whether you’re designing a striking architectural facade, building a robust industrial filter, or simply need a reliable screening solution, crimped wire mesh offers a compelling alternative to other mesh materials. By carefully considering the material, wire diameter, aperture size, and crimp type, you can select the ideal crimped wire mesh solution for your specific needs.

Reviews

There are no reviews yet.