Description

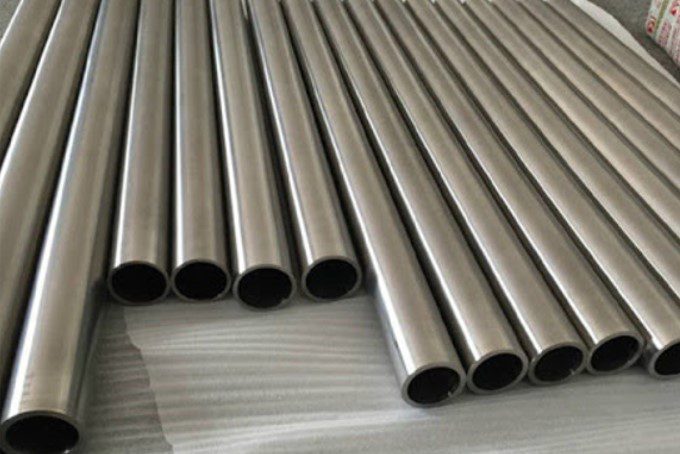

Cold Drawn Seamless Pipes: Strength and Precision in a Single Package

In the world of piping, where reliability and performance are paramount, cold drawn seamless pipes stand out as a top choice for demanding applications. These pipes, manufactured through a meticulous cold drawing process, offer a unique combination of strength, precise dimensions, and superior surface finish, making them ideal for industries ranging from automotive and aerospace to oil and gas and power generation.

What Makes Them Seamless?

The key characteristic that sets cold drawn seamless pipes apart is, as the name suggests, their seamless construction. Unlike welded pipes, which are formed by joining metal sheets, seamless pipes are manufactured from a solid billet of steel. This billet is heated and pierced to create a hollow tube, which is then further processed. This seamless construction eliminates the potential weakness and corrosion points associated with welds, resulting in a pipe with inherently superior structural integrity.

The Cold Drawing Advantage

The “cold drawn” part of the name refers to the crucial stage in the manufacturing process where the pipe is drawn through a die at room temperature (or slightly elevated). This process offers several significant advantages:

- Enhanced Mechanical Properties: Cold drawing increases the yield and tensile strength of the pipe, making it more resistant to deformation and failure under pressure. This is achieved through work hardening, a process where the metal’s grain structure is refined and strengthened.

- Precise Dimensional Tolerances: The cold drawing process allows for tight control over the pipe’s dimensions, including its outer diameter, inner diameter, and wall thickness. This precision is critical in applications where accurate fit and alignment are essential.

- Superior Surface Finish: Cold drawing results in a smooth, clean surface finish, both internally and externally. This smooth surface reduces friction and improves flow characteristics, making it beneficial in systems where efficient fluid transfer is vital.

- Improved Concentricity and Straightness: The drawing process ensures a high degree of concentricity, meaning that the inner and outer diameters are perfectly aligned. It also enhances the straightness of the pipe, minimizing variations and ensuring consistent performance.

Applications Across Industries

The unique properties of cold drawn seamless pipes make them a preferred choice in a wide range of applications:

- Hydraulic Systems: Their high strength and precise dimensions make them ideal for hydraulic lines and cylinders, where they can withstand high pressures and provide reliable performance.

- Automotive Industry: Used for precision tubing in fuel injection systems, brake lines, and suspension components, contributing to vehicle performance and safety.

- Aerospace Industry: Employed in critical components where reliability and weight are crucial, such as landing gear struts and hydraulic systems.

- Oil and Gas Industry: Used for downhole tubing, pipelines, and other demanding applications, where their corrosion resistance and high strength are essential.

- Power Generation: Utilized in high-pressure steam lines and other critical components in power plants, ensuring efficient and safe operation.

- Mechanical Engineering: Used for a variety of structural and mechanical applications due to their strength, precision, and availability in custom sizes.

Choosing the Right Cold Drawn Seamless Pipe

Selecting the appropriate cold drawn seamless pipe involves careful consideration of several factors:

- Material Grade: Different steel alloys offer varying levels of strength, corrosion resistance, and heat resistance. Factors to consider include operating temperature, fluid compatibility, and environmental conditions.

- Dimensions: Precisely specifying the required outer diameter, inner diameter, and wall thickness is crucial for ensuring proper fit and functionality.

- Standards and Certifications: Adherence to relevant industry standards and certifications, such as ASTM, ASME, and API, ensures quality and compliance.

- Surface Finish Requirements: Depending on the application, specific surface finish requirements may need to be considered to optimize flow characteristics or corrosion resistance.

Conclusion

Cold drawn seamless pipes offer a compelling combination of strength, precision, and reliability. Their seamless construction, coupled with the benefits of the cold drawing process, make them a superior choice for demanding applications across a diverse range of industries. By carefully considering the specific requirements of the application and selecting the appropriate pipe material and dimensions, engineers and designers can leverage the advantages of cold drawn seamless pipes to achieve optimal performance and long-term reliability.

Reviews

There are no reviews yet.