Description

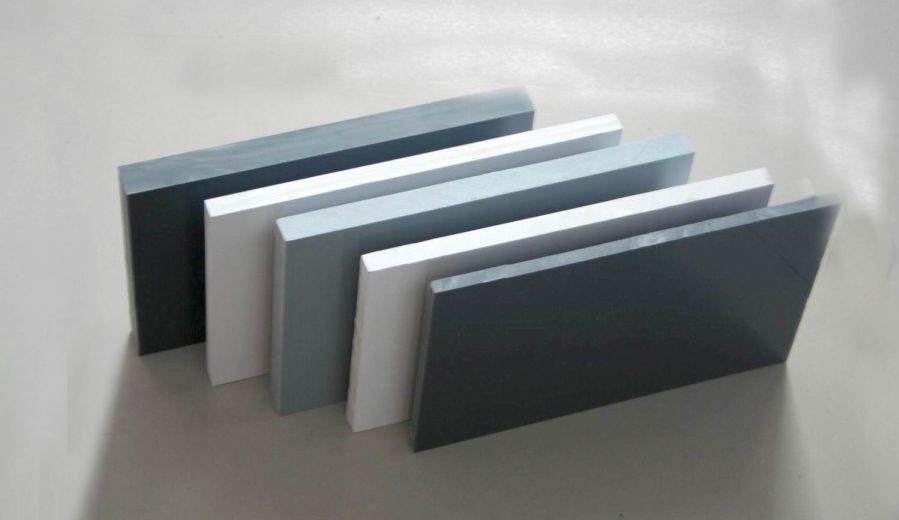

Battle the Elements: Chemical Resistant Sheets for Demanding Applications

In a world where countless industries rely on harsh chemicals for cleaning, manufacturing, and research, the need for robust and reliable protection against corrosion and degradation is paramount. Enter chemical resistant sheets, a versatile material designed to withstand the rigors of these demanding environments. These sheets are not merely a safeguard; they are an investment in longevity, safety, and efficiency.

What are Chemical Resistant Sheets?

Chemical resistant sheets are typically made from high-performance polymers engineered to resist a broad range of chemicals, including:

- Acids: Hydrochloric acid, sulfuric acid, nitric acid

- Bases: Sodium hydroxide, potassium hydroxide

- Solvents: Acetone, toluene, xylene

- Oils: Mineral oils, petroleum-based oils

Popular materials used in their construction include:

- Polypropylene (PP): Known for its excellent resistance to a wide range of chemicals, PP is a cost-effective and versatile option.

- High-Density Polyethylene (HDPE): Offers superior chemical resistance compared to standard polyethylene, making it ideal for alkaline environments.

- Polyvinyl Chloride (PVC): A rigid and durable material with good resistance to acids, alkalis, and salts.

- Fluoropolymers (e.g., PTFE, Teflon): Provide exceptional resistance to virtually all chemicals, even at high temperatures, making them the ultimate choice for the most aggressive environments.

Why Use Chemical Resistant Sheets?

The benefits of using chemical resistant sheets are numerous:

- Enhanced Safety: Protecting employees and the environment from hazardous chemical exposure is crucial. These sheets create a barrier that prevents leaks, spills, and contamination, mitigating risks and ensuring a safer working environment.

- Extended Lifespan: Unlike traditional materials that can quickly degrade under chemical attack, chemical resistant sheets offer exceptional durability, reducing the need for frequent replacements and lowering long-term costs.

- Reduced Maintenance: With their inherent resistance to corrosion and degradation, these sheets require minimal maintenance, saving time and resources.

- Increased Efficiency: By creating a controlled and contained environment, chemical resistant sheets contribute to a smoother and more efficient operation, minimizing downtime and maximizing productivity.

- Versatile Applications: These sheets can be easily fabricated, cut, and welded into a variety of shapes and sizes, making them suitable for a wide range of applications across diverse industries.

Applications Across Industries:

The adaptability of chemical resistant sheets makes them indispensable in various sectors:

- Chemical Processing: Lining tanks, vessels, and pipes to prevent corrosion and contamination.

- Pharmaceuticals: Creating cleanrooms, contained environments, and equipment coverings for sensitive manufacturing processes.

- Laboratories: Protecting work surfaces, fume hoods, and equipment from chemical spills and splashes.

- Wastewater Treatment: Lining tanks and channels to resist corrosive chemicals and prevent leaks.

- Electroplating: Providing a protective barrier against corrosive acids and alkalis.

- Food Processing: Used in areas where sanitation and resistance to cleaning chemicals are essential.

- Automotive: Protecting surfaces and equipment from corrosive fluids and chemicals used in manufacturing and maintenance.

Choosing the Right Chemical Resistant Sheet:

Selecting the appropriate chemical resistant sheet requires careful consideration of several factors:

- Chemical Exposure: Identify the specific chemicals the sheet will be exposed to, their concentrations, and operating temperatures. Consult chemical resistance charts provided by manufacturers to ensure compatibility.

- Thickness and Dimensions: Determine the required thickness based on the expected stress and impact resistance needed. Consider the dimensions of the area to be protected to minimize waste and ensure proper coverage.

- Application Requirements: Evaluate factors such as UV exposure, abrasion resistance, and flammability requirements based on the specific application.

- Cost: Different materials offer varying levels of chemical resistance and cost. Weigh the performance benefits against the budget constraints to make an informed decision.

Conclusion:

Chemical resistant sheets are a vital component in industries that demand robust protection against corrosive chemicals. By choosing the right material and considering the specific application requirements, businesses can significantly enhance safety, prolong the lifespan of equipment, reduce maintenance costs, and improve overall efficiency. Investing in chemical resistant sheets is an investment in long-term success and a safer, more sustainable future.

Reviews

There are no reviews yet.