Description

Activated Carbon: The Unsung Hero of Food and Beverage Processing

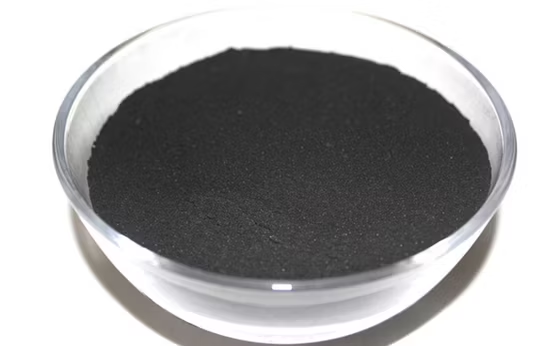

In the bustling world of food and beverage production, where purity, taste, and appearance are paramount, there’s an unsung hero working tirelessly behind the scenes: activated carbon. This versatile material, often overlooked, plays a crucial role in removing unwanted impurities, enhancing the quality, and ensuring the safety of a wide range of products we consume daily.

Activated carbon isn’t just ordinary charcoal. It’s a specially treated form of carbon with an incredibly porous structure and a massive surface area, often exceeding 500 square meters per gram. This vast surface area allows it to act like a super-sponge, effectively adsorbing (binding to its surface) a wide variety of substances, including:

- Undesirable Colors: From removing unwanted pigments in sugar refining to clarifying fruit juices and vegetable oils, activated carbon ensures a clear and appealing final product.

- Off-Flavors and Odors: Imagine a beer with an unpleasant aftertaste or a juice smelling faintly of mold. Activated carbon prevents these issues by adsorbing compounds responsible for off-flavors and odors, leading to a more enjoyable sensory experience.

- Organic Contaminants: In today’s world, trace amounts of pesticides, herbicides, and other organic contaminants can find their way into our food supply. Activated carbon acts as a safeguard, removing these unwanted compounds and ensuring product safety.

- Precursors to Discoloration and Oxidation: By removing compounds that can lead to browning or rancidity, activated carbon extends the shelf life and maintains the quality of various food and beverage products.

Applications Across the Food and Beverage Spectrum:

The applications of activated carbon in food and beverage processing are diverse and far-reaching:

- Sugar Refining: This is perhaps the most well-known application, where activated carbon removes color bodies and other impurities from raw sugar solutions, resulting in refined white sugar.

- Beverage Production: From clarifying wines and beers to purifying fruit juices and removing chlorine from water used in beverage production, activated carbon is essential for producing high-quality drinks.

- Edible Oil Processing: Activated carbon removes color pigments, oxidation products, and other impurities from vegetable oils, resulting in a clear, stable, and palatable product.

- Food Ingredient Production: In the production of ingredients like citric acid, glucose syrups, and amino acids, activated carbon plays a crucial role in purifying the final product.

- Water Treatment: Removing chlorine, organic compounds, and other contaminants from water is essential for producing safe and high-quality food and beverages. Activated carbon is widely used in water treatment processes within the industry.

Choosing the Right Activated Carbon:

Not all activated carbon is created equal. The effectiveness of activated carbon depends on factors like:

- Pore Size Distribution: The size of the pores determines which molecules can be effectively adsorbed. Different applications require different pore size distributions.

- Surface Area: A higher surface area generally translates to a greater adsorption capacity.

- Raw Material: Activated carbon can be produced from various raw materials, including coal, wood, coconut shell, and peat. The choice of raw material can influence the properties of the final product.

- Activation Method: The method used to activate the carbon (e.g., steam activation or chemical activation) also affects its properties and performance.

Therefore, selecting the right type of activated carbon is crucial for achieving optimal results. Food and beverage manufacturers should work with reputable suppliers who can provide technical support and guidance in choosing the most appropriate product for their specific application.

The Future of Activated Carbon in Food and Beverage:

As consumer demands for higher quality, safer, and more sustainable food and beverage products continue to grow, the role of activated carbon is likely to expand even further. Ongoing research and development are focused on improving the efficiency and sustainability of activated carbon production and exploring its potential in emerging applications, such as removing microplastics from food and beverage products.

In conclusion, activated carbon may be a hidden component in the food and beverage industry, but its impact is undeniable. It’s a powerful and versatile tool that ensures the purity, taste, and safety of the products we enjoy every day, making it a truly essential ingredient for a healthier and more delicious world.

Reviews

There are no reviews yet.