Description

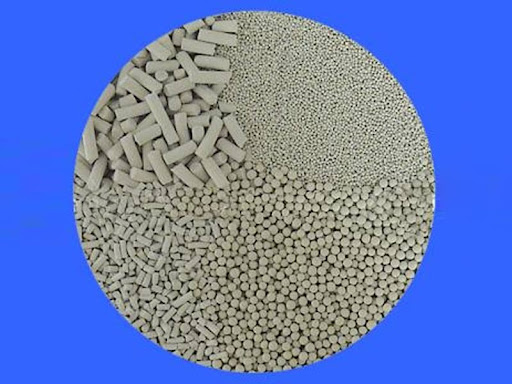

5A Molecular Sieve: The Workhorse of Adsorption and Separation

In the world of chemical processing, purification, and separation, molecular sieves play a crucial role. Among these versatile materials, the 5A molecular sieve stands out as a particularly valuable workhorse, known for its unique pore size and broad range of applications.

What is a 5A Molecular Sieve?

5A molecular sieves are aluminosilicate crystals, synthetic zeolites, characterized by a precise and uniform pore size of 5 Angstroms (Å). This precisely defined aperture allows the sieve to selectively adsorb molecules based on their size and shape. A crucial difference between 5A and other molecular sieves like 3A or 4A lies in its cation composition, primarily containing calcium ions. This modification results in the 5Å pore opening, which is perfect for adsorbing molecules up to that size.

How Does it Work? The Principle of Adsorption

The core functionality of 5A molecular sieve relies on the principle of adsorption. This is a surface phenomenon where molecules from a gas or liquid phase are attracted to and adhere to the surface of the solid sieve material. This attraction is due to the electrostatic forces between the polar molecules of the adsorbate and the highly polar surface of the zeolite crystal. The larger the surface area, the greater the adsorption capacity.

Because of its 5Å pore, 5A molecular sieve excels at adsorbing molecules such as:

- Water (H2O)

- Carbon Dioxide (CO2)

- Hydrocarbons (alkanes, alkenes, alkynes) up to C4

- Hydrogen Sulfide (H2S)

- Other Polar Molecules within size constraints

Importantly, larger molecules, like branched hydrocarbons or aromatic compounds, are excluded due to their size, making the separation process highly selective.

Key Applications of 5A Molecular Sieve:

The unique properties of 5A molecular sieve make it indispensable in a wide array of industries, including:

- Air Drying & Purification: Removing moisture from compressed air systems, cryogenic air separation units, and instrument air lines. This prevents corrosion and allows for efficient operation of downstream equipment.

- Ethanol Dehydration: Drying ethanol for use as a biofuel or solvent. 5A molecular sieve is the preferred choice for this process due to its high selectivity for water over ethanol.

- Natural Gas Drying & Sweetening: Removing water and CO2 from natural gas streams to prevent hydrate formation and improve the gas’s heating value.

- PSA (Pressure Swing Adsorption) Systems: Used in PSA units to separate gases like oxygen and nitrogen from air. The alternating adsorption and desorption cycles enable continuous production of high-purity gases.

- Cryogenic Drying: Removing trace amounts of water and other impurities from cryogenic liquids like liquid nitrogen and liquid oxygen.

- Refrigerant Drying: Drying refrigerants to prevent corrosion and ensure efficient performance of refrigeration systems.

Advantages of Using 5A Molecular Sieve:

- High Adsorption Capacity: Enables the sieve to remove a significant amount of target molecules, leading to efficient purification.

- Excellent Selectivity: The precise pore size allows for the selective adsorption of specific molecules while excluding others.

- Regenerability: Can be regenerated by heating and purging, allowing for repeated use and reducing operational costs.

- High Mechanical Strength: Provides durability and prevents attrition during operation.

- Long Service Life: Properly maintained, 5A molecular sieve can offer a long and reliable service life.

Regeneration: Extending the Life of Your Sieve

The adsorption capacity of 5A molecular sieve is not infinite. Eventually, the pores become saturated, and the sieve needs to be regenerated. Regeneration typically involves heating the sieve to temperatures between 200°C and 315°C (392°F and 600°F) under a flow of dry gas (like nitrogen or air). This process drives off the adsorbed molecules, restoring the sieve’s original adsorption capacity. The frequency of regeneration depends on the application and the concentration of the adsorbate.

Conclusion:

The 5A molecular sieve stands out as a versatile and reliable material with a crucial role in various industrial applications. Its precise pore size, high adsorption capacity, excellent selectivity, and regenerability make it an invaluable tool for purifying, drying, and separating gases and liquids. As industries continue to demand higher purity products and more efficient processes, the 5A molecular sieve will undoubtedly remain a vital component in various purification and separation applications.

Reviews

There are no reviews yet.