Description

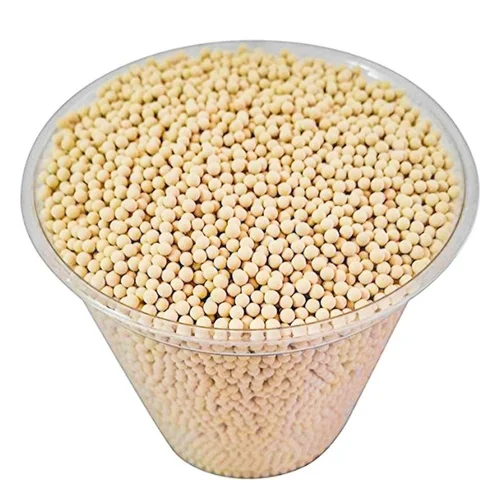

4A Bead Molecular Sieve: The Tiny Giant of Purification and Separation

In the world of chemical processing and industrial applications, purity and precise separation are paramount. Enter the 4A bead molecular sieve – a seemingly simple material with an impressive capacity to selectively adsorb molecules based on their size. This article delves into the properties, applications, and significance of this versatile material.

Understanding Molecular Sieves

Molecular sieves are crystalline aluminosilicates with a highly porous structure. This structure consists of interconnected cavities and channels of uniform and precisely defined size. Think of them as extremely fine sieves at the molecular level. This allows them to selectively adsorb molecules that are small enough to enter the pores, while excluding larger molecules.

The Specifics of 4A Beads

The “4A” designation in 4A bead molecular sieve refers to the size of the pores – approximately 4 Angstroms (0.4 nanometers). This specific pore size makes it particularly effective for adsorbing molecules with kinetic diameters smaller than 4 Angstroms.

Key Properties of 4A Beads

- High Adsorption Capacity: 4A beads possess a significant capacity for adsorbing water, CO2, H2S, and other similarly sized molecules.

- Selectivity: The precisely defined pore size ensures that only molecules fitting within the 4A diameter are adsorbed, leading to highly selective separation.

- Regenerability: After saturation, 4A beads can be regenerated through heating or pressure reduction, allowing for repeated use and cost-effectiveness.

- Chemical Stability: They exhibit good resistance to a wide range of chemicals, ensuring long-term performance in various environments.

- Mechanical Strength: Formulated as beads, they offer good resistance to crushing and abrasion, crucial for demanding industrial applications.

Applications Across Diverse Industries

The unique properties of 4A bead molecular sieve make it indispensable across various sectors:

- Drying of Liquids and Gases: A primary application is drying solvents, refrigerants, and natural gas. Removing water improves processing efficiency, prevents corrosion, and ensures product quality.

- Air Separation: 4A beads play a critical role in air separation units, particularly in the pressure swing adsorption (PSA) process for producing oxygen and nitrogen.

- Removal of CO2 and H2S: In the natural gas and biogas industries, 4A beads are used to remove acid gases like CO2 and H2S, improving gas quality for transport and utilization.

- Dehydration in Packaging: They are used in packaging for pharmaceuticals, electronics, and diagnostic kits to maintain a dry environment and prevent degradation of sensitive materials.

- Catalysis Support: In some catalytic processes, 4A beads serve as support materials for catalysts, providing a high surface area and controlled environment for reactions.

- Ethanol Dehydration: 4A molecular sieves are widely used in the production of fuel-grade ethanol by removing water from the ethanol-water mixture.

Advantages and Considerations

Choosing 4A bead molecular sieve offers significant advantages:

- Effective Removal of Specific Contaminants: Its selective adsorption allows precise purification and separation.

- Cost-Effective Solution: The regenerability of the material reduces the need for frequent replacements, leading to long-term cost savings.

- Improved Product Quality: By removing water and other impurities, it enhances the quality and shelf life of processed products.

- Enhanced Process Efficiency: Drying and purification contribute to more efficient and reliable industrial processes.

However, there are considerations to bear in mind:

- Pre-Treatment: Feed streams should be free of dust and particulates to prevent pore blockage.

- Regeneration Requirements: Optimal regeneration requires specific temperature and pressure conditions, which must be carefully controlled.

- Specific Application Needs: Selecting the right molecular sieve requires careful consideration of the target molecules and process conditions.

The Future of Molecular Sieve Technology

Ongoing research and development are focused on improving the performance, selectivity, and stability of molecular sieves, including 4A beads. New formulations, modified pore structures, and advanced regeneration techniques are being explored to further enhance their capabilities. This continuous innovation promises to expand the application of 4A bead molecular sieve and other molecular sieves in a wide range of emerging technologies.

In conclusion, the 4A bead molecular sieve, despite its small size, is a powerful tool for purification and separation in various industries. Its unique combination of selectivity, high adsorption capacity, and regenerability makes it a valuable asset for achieving product quality, process efficiency, and sustainability. As industries continue to demand higher purity and more efficient separation techniques, the 4A molecular sieve, along with its molecular sieve counterparts, will undoubtedly play an increasingly important role.

Reviews

There are no reviews yet.