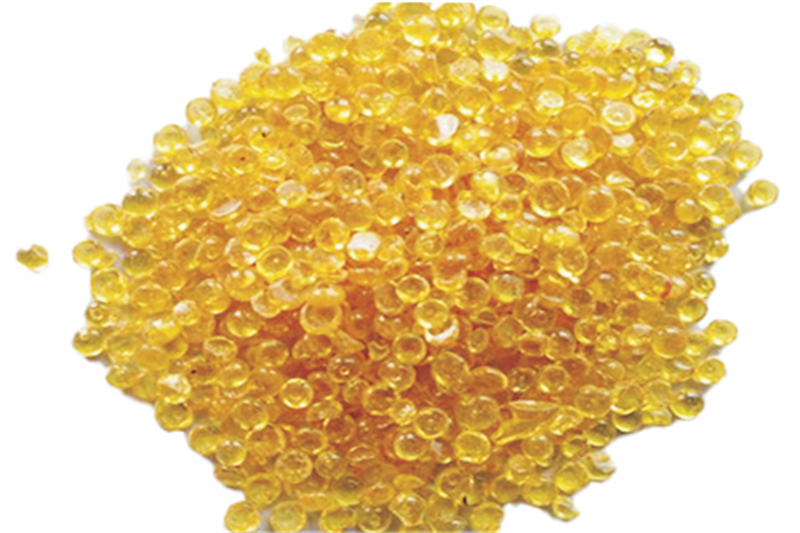

Description

Phenolic Resins

Phenolic resins are a family of synthetic polymers made from phenol (or substituted phenols) and formaldehyde. They are among the oldest synthetic polymers and are known for their heat resistance, dimensional stability, and good chemical resistance. They are used in a wide range of applications from early electrical insulators to modern high-pressure laminates and aerospace components.

Chemistry and main types

-

Basic chemistry: Phenol reacts with formaldehyde to form hydroxymethyl phenols, which further react to create methylene and dimethylol bridges. The balance of reactions and the ratio of starting materials determine the resin’s structure and curing behavior.

-

Two main commercial families:

- Novolac resins (phenol-formaldehyde, PF):

- Prepared with a sub-stoichiometric amount of formaldehyde (low MF ratio).

- Do not cure on their own; require an external curing agent to crosslink.

- Resols (resol resins):

- Prepared with excess formaldehyde (high MF ratio) and typically formed under basic conditions.

- Contain reactive methylol groups and can cure thermally with little or no added curing agent.

- Novolac resins (phenol-formaldehyde, PF):

-

Curing behavior in brief:

- Novolac resins crosslink when an external curing agent (such as hexamethylenetetramine HMTA or other methylene donors) is heated, releasing formaldehyde and forming a robust network.

- Resol resins cure upon heating due to the condensation of residual methylol groups and methylene bridges, often aided by acids or other catalysts.

Synthesis and curing: a quick outline

- Preparation under controlled pH:

- Phenol and formaldehyde are reacted under acidic conditions to form methylol phenols (and related species).

- Polymer formation:

- Depending on the MF ratio and conditions, the system yields either novolac (lower molecular weight, needs crosslinker) or resol (higher molecular weight, self-curing).

- Curing (final setting):

- Novolac: cure with external hardener (e.g., HMTA) at elevated temperature.

- Resol: cure upon heating in the presence of catalysts or simply by heat, forming a dense, thermoset network.

Properties and performance

- Thermal stability: Excellent heat resistance and flame retardancy, especially in molded parts and laminates.

- Chemical resistance: Good resistance to water, acids, and many solvents.

- Mechanical behavior: High stiffness and hardness; can be brittle if not modified.

- Dimensional stability: Low moisture expansion; good aging resistance.

- Color and processing: Generally dark to reddish-brown; processing can be challenging for some formulations due to brittleness or moisture sensitivity.

- Hazards: Formaldehyde release during curing; handling phenol and formaldehyde requires proper ventilation and controls.

Applications and processing forms

- Electrical and electronic: Bakelite-type molded parts, insulators, switchgear components.

- Laminates and composites: High-pressure laminates (HPL) with paper or fiberglass; binder systems in brake linings, friction materials.

- Adhesives and binders: Wood and non-wood adhesives; foundry binders; fiber-reinforced composites.

- Moldings and powders: Phenolic molding powders for ornate shapes and durable parts.

- Foams: Phenolic foams used for insulation and impact resistance (specific formulations).

Quick comparison: Novolac vs Resol

| Property / Type | Novolac PF | Resol PF |

|---|---|---|

| Typical MF ratio | Sub-stoichiometric (less formaldehyde) | Excess formaldehyde |

| Curing behavior | Requires external curing agent (e.g., HMTA) | Self-curing upon heating; may use catalysts |

| Primary crosslinking species | Crosslinks formed with external agent upon heating | Methylene bridges formed during heating |

| Common curing conditions | Elevated temperature with curing agent (often 120–180°C) | Elevated temperature; often acidic or catalyzed environments |

| Typical uses | Thermoset laminates, coatings, and adhesives where a crosslinker is convenient | Molded parts, thermoset binders, and high-temperature applications |

| Processing form | Powder or solution forms; needs crosslinker | Solutions or melts that cure with heat |

Processing considerations and tips

- Formulation choice: Choose novolac when you want a stable resin that cures with a controlled external hardener. Choose resol when you want a resin that cures more readily with heat and fewer additives.

- Cure schedule: Cure temperatures and times depend on resin type, additives, and desired properties. Always follow the manufacturer’s recommended cure profile.

- Fillers and tougheners: Add fillers (e.g., glass, minerals) or toughening agents to improve toughness and reduce brittleness.

- Environmental controls: Manage formaldehyde exposure during synthesis and curing; use appropriate ventilation and containment.

Safety and environmental considerations

- Formaldehyde exposure is a key safety concern; handle with appropriate engineering controls and PPE.

- Phenol is toxic and corrosive; handle with care and proper ventilation.

- Some phenolic resins can release hazardous byproducts during combustion; use in well-ventilated facilities and with proper fire safety measures.

Key takeaways

- Phenolic resins are versatile thermosetting polymers derived from phenol and formaldehyde, existing mainly as novolac and resol types.

- Novolac resins need an external curing agent, while resol resins cure upon heating due to residual reactive groups.

- They offer excellent heat and chemical resistance, making them ideal for laminates, molded parts, adhesives, and high-temperature applications.

- Safety and environmental controls are important due to formaldehyde and phenol handling.

If you’d like, I can tailor this overview to a specific application (for example, electrical insulation, wood adhesives, or carbon fiber composites) and include more detailed processing guidelines or a materials selection checklist.

Reviews

There are no reviews yet.