Description

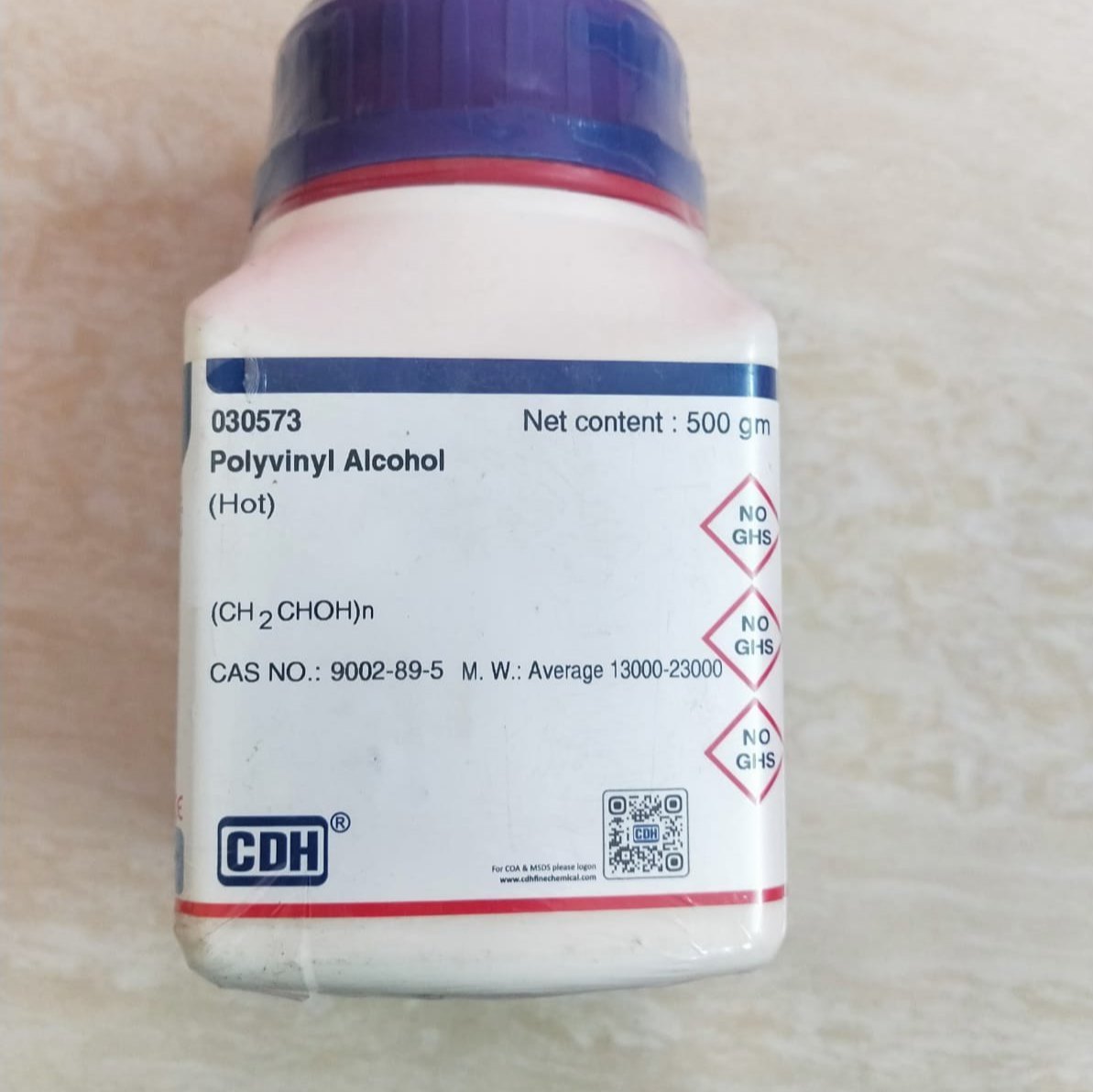

The Unsung Hero of Modern Material Science: Exploring the Versatile World of Polyvinyl Alcohol (PVA)

Polyvinyl alcohol (PVA), often overlooked in everyday conversations, is a fascinating and incredibly versatile synthetic polymer with a wide range of applications impacting industries from packaging and textiles to medicine and construction. This water-soluble polymer boasts a unique combination of properties that make it an invaluable tool in countless processes, earning it a quiet but significant role in shaping the world around us.

What Exactly is Polyvinyl Alcohol?

PVA, unlike many plastics derived directly from petroleum, is produced by hydrolyzing polyvinyl acetate (PVAc). This process, often referred to as alcoholysis, replaces the acetate groups in PVAc with hydroxyl groups, resulting in the water-soluble PVA. The degree of hydrolysis, or the percentage of acetate groups replaced, determines the PVA’s properties, particularly its water solubility and film strength.

A Polymer of Many Talents: Key Properties of PVA

PVA’s versatility stems from its unique blend of characteristics:

- Water Solubility: This is arguably PVA’s most defining trait. It dissolves readily in water (especially hot water), allowing for easy manipulation and application in aqueous environments. This makes it ideal for formulations requiring water-based solutions.

- Film-Forming Ability: Upon drying, PVA forms strong, flexible, and clear films. These films possess excellent tensile strength and are resistant to solvents, oils, and greases.

- Biodegradability: While not as rapidly biodegradable as some natural materials, PVA is significantly more biodegradable than many traditional plastics, making it a more environmentally conscious choice for certain applications.

- Non-Toxicity: Generally considered non-toxic, PVA is safe to use in a variety of applications, including food packaging and medical devices.

- Adhesive Properties: PVA exhibits excellent adhesive properties, making it a valuable component in glues, adhesives, and coatings.

A Wide Spectrum of Applications: Where You’ll Find PVA

PVA’s diverse properties translate into a remarkable range of applications across numerous industries:

- Packaging: PVA is used in films for food packaging, offering excellent barrier properties against oxygen and aromas. It is also used in edible films for encapsulating ingredients and delivering flavors.

- Textiles: PVA is employed as a sizing agent in the textile industry to improve yarn strength and weaveability. It also serves as a temporary support material in embroidery and other textile processes.

- Adhesives: PVA is a key ingredient in many glues and adhesives, providing strong bonding strength for paper, wood, and other materials. Think of that school glue you used as a kid – chances are it contained PVA!

- Construction: PVA is used as a binder in cement and mortar, improving their workability and adhesion. It also serves as a component in coatings for protecting concrete from water damage.

- Medical Applications: PVA finds use in biomedical applications, including wound dressings, drug delivery systems, and artificial cartilage. Its biocompatibility and ability to form hydrogels make it suitable for these purposes.

- 3D Printing: PVA is frequently used as a support material in 3D printing, particularly for complex geometries. Its water solubility allows for easy removal after the printing process is complete.

- Cosmetics: PVA is found in some cosmetic products, acting as a film former and binder to improve texture and application.

Looking Ahead: The Future of PVA

As concerns about sustainability and environmental impact grow, PVA is gaining even more attention. Ongoing research is focused on further enhancing its biodegradability and exploring new applications in areas like bio-plastics and sustainable packaging. The development of bio-based PVA, derived from renewable resources, promises to further reduce its environmental footprint.

Conclusion

Polyvinyl alcohol, while often hidden from plain sight, is a powerful and versatile material that plays a significant role in modern industry. Its unique combination of properties, including water solubility, film-forming ability, and biodegradability (relative to other plastics), makes it an indispensable tool in a wide range of applications. As research continues to unlock its full potential, PVA is poised to play an even more prominent role in building a more sustainable and innovative future.

Reviews

There are no reviews yet.