Description

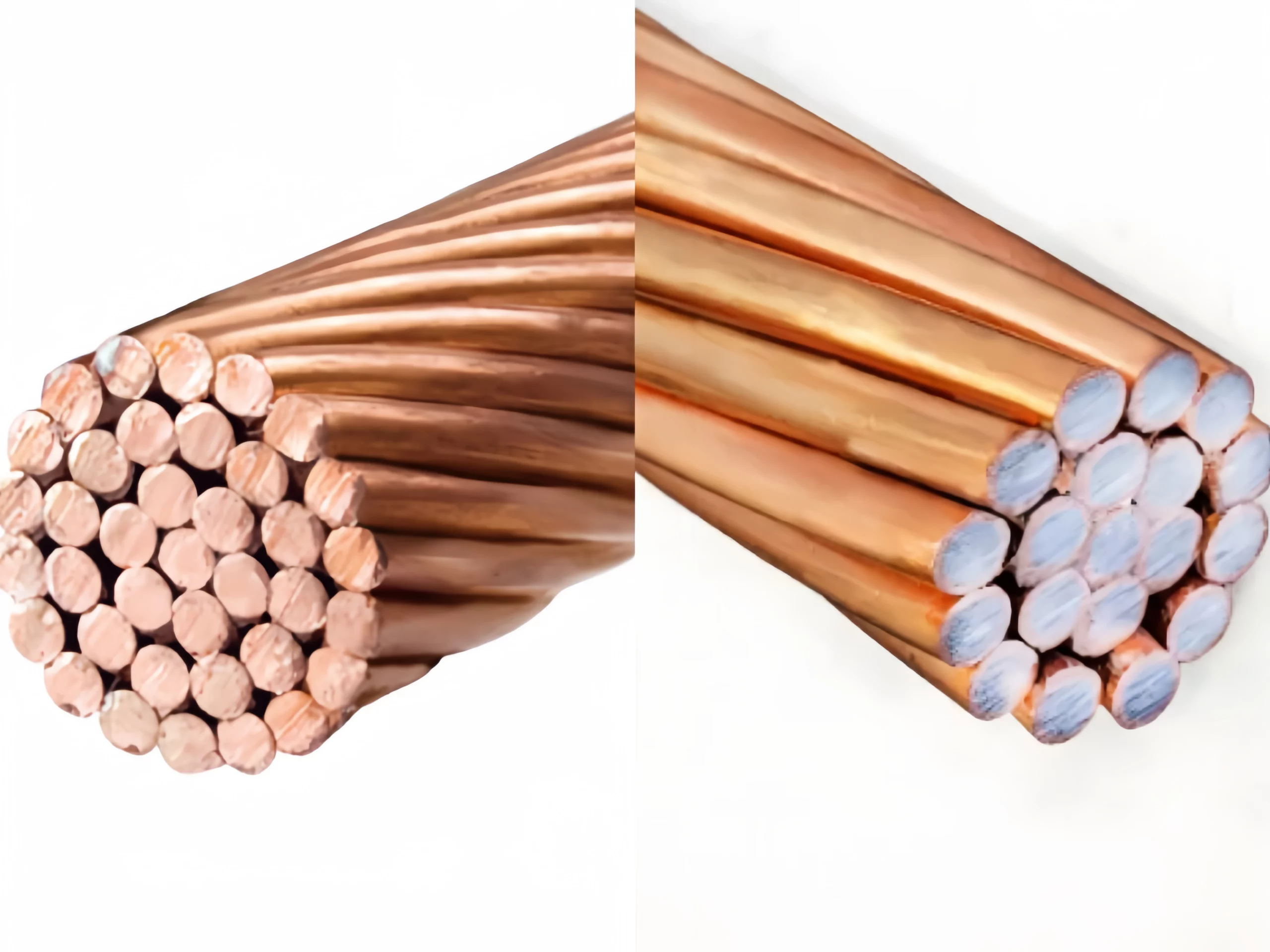

Copper-Coated Steel Pipes: A Powerful Hybrid for Modern Plumbing and Beyond

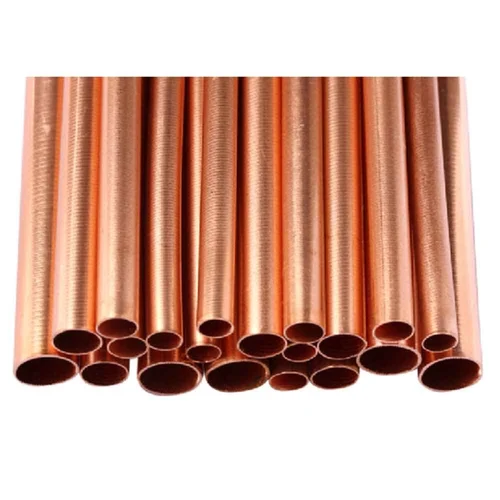

In the world of piping systems, innovation is key. Engineers and manufacturers constantly strive to improve material properties, durability, and cost-effectiveness. Enter copper-coated steel pipes – a compelling hybrid solution that combines the strengths of both materials, offering a unique blend of benefits for a range of applications.

The Best of Both Worlds: Copper and Steel

At its core, a copper-coated steel pipe consists of a steel core, typically carbon steel, covered with a layer of copper. This seemingly simple construction yields a powerful combination of properties:

- Strength and Durability (Steel): The steel core provides exceptional strength and structural integrity. This allows for thinner pipe walls compared to pure copper, leading to weight reduction and cost savings. The inherent robustness of steel also makes these pipes highly resistant to mechanical damage and deformation.

- Corrosion Resistance and Antimicrobial Properties (Copper): The copper outer layer acts as a protective shield, safeguarding the steel core from corrosion. Copper is known for its excellent resistance to oxidation, pitting, and scaling, extending the lifespan of the piping system. Moreover, copper naturally possesses antimicrobial properties, inhibiting the growth of bacteria and other microorganisms, making it ideal for potable water applications.

Advantages of Copper-Coated Steel Pipes

The unique combination of properties translates into several key advantages:

- Cost-Effectiveness: Compared to pure copper pipes, copper-coated steel pipes offer significant cost savings due to the reduced copper content. This makes them an attractive option for large-scale projects where material costs are a major consideration.

- Improved Durability and Longevity: The robust steel core and the protective copper layer result in a piping system that is highly durable and resistant to corrosion, leading to a longer lifespan and reduced maintenance costs.

- Enhanced Heat Transfer: Copper is an excellent conductor of heat. The copper coating improves heat transfer efficiency compared to purely steel pipes, making them suitable for applications where temperature regulation is critical.

- Ease of Installation: While welding methods vary depending on the coating thickness and application, many copper-coated steel pipes are compatible with standard copper piping connection methods such as soldering, brazing, and mechanical fittings. This simplifies installation and reduces labor costs.

- Versatility: Copper-coated steel pipes are suitable for a wide range of applications, including potable water systems, heating and cooling systems, industrial piping, and more.

Applications of Copper-Coated Steel Pipes

The versatility of copper-coated steel pipes makes them suitable for a diverse range of applications:

- Potable Water Systems: The antimicrobial properties of copper and the strength of steel make these pipes an excellent choice for potable water distribution systems in residential, commercial, and industrial buildings.

- Heating and Cooling Systems: The enhanced heat transfer capabilities make them suitable for heating and cooling systems, including radiant floor heating, chilled water lines, and steam distribution systems.

- Industrial Piping: Copper-coated steel pipes are used in various industrial applications, including chemical processing, pharmaceutical manufacturing, and food and beverage production, where corrosion resistance and durability are critical.

- Gas Distribution: In some applications, they are used for gas distribution, leveraging the strength of steel and the corrosion resistance of copper.

Considerations and Future Trends

While copper-coated steel pipes offer numerous advantages, some considerations should be kept in mind:

- Coating Thickness and Quality: The performance of copper-coated steel pipes depends heavily on the thickness and quality of the copper coating. Careful selection of suppliers and adherence to industry standards are crucial to ensure optimal performance.

- Jointing Methods: Choosing the appropriate jointing method is essential to maintain the integrity of the piping system and prevent corrosion at the joints.

Looking ahead, the demand for copper-coated steel pipes is expected to grow as industries seek more cost-effective and durable piping solutions. Ongoing research and development efforts are focused on improving coating technologies, enhancing corrosion resistance, and exploring new applications for these versatile pipes.

Conclusion

Copper-coated steel pipes represent a significant advancement in piping technology, offering a compelling blend of strength, durability, corrosion resistance, and cost-effectiveness. As the demand for sustainable and efficient building materials continues to rise, these hybrid pipes are poised to play an increasingly important role in modern infrastructure and industrial applications. By understanding the benefits and limitations of copper-coated steel pipes, engineers and specifiers can make informed decisions and leverage the power of this innovative material to create more reliable and long-lasting piping systems.

Reviews

There are no reviews yet.