Description

Polyether: A Versatile Polymer Shaping Modern Industries

Polyether (PE), a robust and versatile class of polymers, is quietly revolutionizing numerous industries. From everyday consumer goods to specialized medical applications, its unique properties make it a vital component in a wide range of products. Understanding polyether, its types, and applications is crucial to appreciating its significance in modern materials science.

What is Polyether?

At its core, polyether is a polymer containing an ether group (-O-) in its main chain. This seemingly simple structural element imparts significant characteristics, including flexibility, resistance to degradation, and excellent solubility in various solvents. The presence of the ether linkage also contributes to its relatively low toxicity, making it suitable for applications demanding biocompatibility.

A Family of Polymers: Different Types of Polyether

The term “polyether” encompasses a broad range of polymers, each tailored for specific applications. Some of the most prominent include:

- Polyethylene Glycol (PEG): Perhaps the most well-known, PEG is a water-soluble, non-toxic polymer valued for its biocompatibility. It’s widely used in pharmaceuticals, cosmetics, and as a lubricant.

- Polypropylene Glycol (PPG): Similar to PEG, PPG is less water-soluble and often used in the production of polyurethane foams, coatings, and elastomers. Its lower toxicity and good thermal stability also make it suitable for food-grade applications.

- Polytetramethylene Ether Glycol (PTMEG): Renowned for its flexibility, elasticity, and resistance to hydrolysis, PTMEG is a key component in high-performance elastomers, adhesives, and textile fibers.

- Polyoxymethylene (POM) or Acetal: Also known as acetal resin, POM offers high rigidity, dimensional stability, and resistance to chemicals and wear. It’s commonly used in automotive parts, gears, and precision machine components.

Applications Across Diverse Industries:

The unique properties of polyether have led to its widespread adoption across a multitude of sectors:

- Pharmaceuticals: PEG’s biocompatibility makes it invaluable in drug delivery systems, where it can enhance drug solubility, stability, and circulation time. It’s also used as a laxative and a base for ointments.

- Cosmetics: PEG and PPG derivatives act as emulsifiers, surfactants, and humectants in personal care products, contributing to their texture, stability, and moisturizing properties.

- Automotive: POM finds extensive use in automotive components like fuel system parts, interior trim, and gears due to its strength, durability, and resistance to fuels and lubricants.

- Textiles: PTMEG is crucial in the production of spandex fibers, providing the stretch and recovery properties essential for comfortable and durable clothing.

- Adhesives and Sealants: Polyether-based adhesives offer excellent bonding strength, flexibility, and resistance to environmental factors, making them ideal for construction, automotive, and aerospace applications.

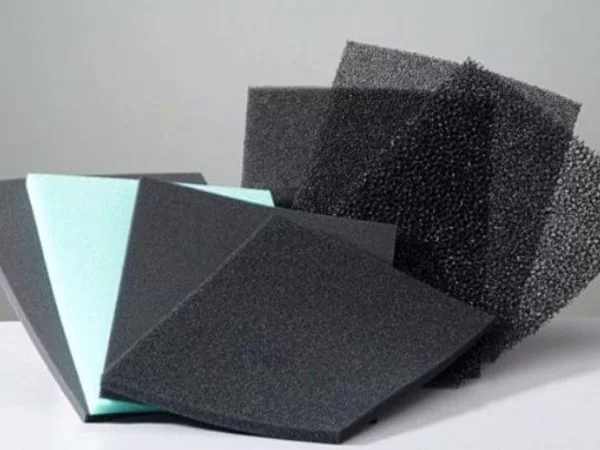

- Polyurethane Industry: PPG is a key building block for polyurethane foams used in furniture, insulation, and automotive seating. The properties of the resulting polyurethane can be tailored by adjusting the type and amount of polyether used.

- Medical Devices: PEG is utilized in hydrogels for wound dressings, contact lenses, and as a coating for medical implants to improve biocompatibility and reduce rejection rates.

Advantages and Disadvantages of Polyether:

Like any material, polyether has its strengths and weaknesses:

Advantages:

- Flexibility: Allows for the creation of flexible and resilient materials.

- Chemical Resistance: Resists degradation from many chemicals, solvents, and environmental factors.

- Biocompatibility (for certain types like PEG): Makes it suitable for medical and pharmaceutical applications.

- Low Toxicity: Generally considered non-toxic, particularly PEG and PPG.

- Solubility (in certain solvents): Facilitates processing and formulation.

Disadvantages:

- Flammability: Some polyethers can be flammable.

- Hydrolytic Degradation (for certain types): Can degrade in the presence of water under specific conditions.

- Cost: Can be more expensive than some other polymers.

The Future of Polyether:

The future of polyether is bright. Ongoing research is focused on developing new and improved polyether materials with enhanced properties, such as increased strength, improved biodegradability, and enhanced functionality for specialized applications. Bio-based polyethers are also gaining traction, offering a more sustainable alternative to traditional petroleum-derived materials.

In conclusion, polyether is a versatile and indispensable polymer that plays a vital role in numerous industries. Its unique combination of properties, coupled with ongoing innovation, ensures its continued importance in shaping the materials of the future. As technology advances and sustainability becomes increasingly important, polyether will undoubtedly continue to evolve and adapt to meet the ever-changing demands of the modern world.

Reviews

There are no reviews yet.