Description

Title: Vulcanizing Agents: Understanding Their Role and Importance in Rubber Production

Introduction:

When it comes to rubber production, vulcanizing agents play a crucial role. These vital components help to improve the overall quality, durability, and elasticity of rubber products. By understanding the role of vulcanizing agents, we can appreciate their significance in various industries, such as automotive, construction, and manufacturing. This article will delve into the concept of vulcanizing agents, their types, applications, and safety measures.

What are Vulcanizing Agents?

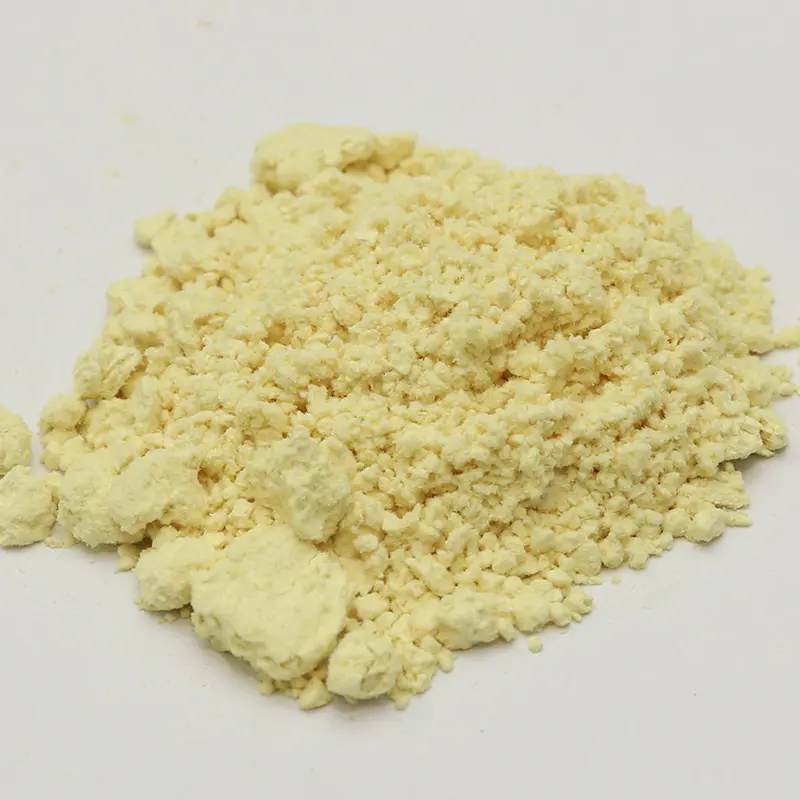

Vulcanizing agents are chemical compounds used to transform raw, unprocessed rubber into a more durable and elastic material. This process, known as vulcanization, stabilizes rubber’s molecular structure, enhancing its resistance to heat, cold, and mechanical stress. Commonly used vulcanizing agents include sulfur, sulfur donors, peroxides, and quinones.

Role and Importance:

The primary function of vulcanizing agents is to create cross-links between rubber’s polymer chains, which ultimately enhances the material’s strength and durability. By limiting the movement of polymer chains, these agents prevent rubber from becoming too soft or too brittle. In turn, this improves the overall performance and lifespan of rubber products.

Types of Vulcanizing Agents:

- Sulfur: Sulfur is the most widely used vulcanizing agent. It reacts with rubber’s double bonds, creating sulfur bridges that bind polymer chains together. This interaction results in improved elasticity and resistance to wear and tear.

- Sulfur Donors: Sulfur donors, such as thiurams, dithiocarbamates, and thiazoles, are used when lower sulfur concentrations are required. These agents release sulfur during vulcanization, which then reacts with the rubber, creating cross-links.

- Peroxides: Peroxides, like dicumyl peroxide and benzoyl peroxide, are used for heat-resistant rubbers. They create carbon-carbon bonds between rubber molecules, resulting in stronger cross-links.

- Quinones: Quinones, including 2,5-dimercapto-1,3,4-thiadiazole (DMTD) and 4,4′-dithiodimorpholine (DTDM), are used to vulcanize elastomers with high unsaturation levels.

Applications and Industries:

Vulcanizing agents are essential in multiple industries, such as:

- Automotive: Vulcanizing agents play a crucial role in tire production, enhancing their durability, resistance to wear, and overall performance.

- Construction: In the construction sector, these agents contribute to the production of seals, gaskets, and hoses, which are used in various applications, including plumbing and HVAC systems.

- Manufacturing: Vulcanizing agents are indispensable in the manufacturing of rubber products, such as conveyor belts, rubber sheets, and molded rubber parts.

Safety Measures and Precautions:

When handling vulcanizing agents, it is essential to follow safety guidelines to prevent potential health risks:

- Personal Protective Equipment (PPE): Always wear protective gear, including gloves, safety glasses, and lab coats, when handling these agents.

- Ventilation: Ensure proper ventilation to minimize exposure to harmful fumes.

- Material Compatibility: Confirm that the selected vulcanizing agent is compatible with the rubber being processed.

- Storage: Store vulcanizing agents in a cool, dry, and well-ventilated area away from heat sources and incompatible materials.

- Training: Provide proper training to employees on how to handle and store vulcanizing agents safely.

Conclusion:

Vulcanizing agents are indispensable in the rubber production process, enhancing the material’s strength, durability, and elasticity. By understanding their role and importance, we can appreciate their significance in various industries and ensure their safe handling and storage. As a result, vulcanizing agents contribute to improved product performance, extending the lifespan and reliability of rubber products.

Reviews

There are no reviews yet.