Description

Ultra Fine Wire Mesh: A Material Revolutionizing Industries

Ultra fine wire mesh, a marvel of modern engineering, is rapidly becoming a cornerstone material across a diverse range of industries. This sophisticated fabric, woven from incredibly thin wires, offers a unique combination of properties that make it invaluable for applications requiring precision, filtration, and structural integrity on a micro scale. Let’s delve into the world of ultra fine wire mesh and explore its properties, applications, and the future it promises.

What is Ultra Fine Wire Mesh?

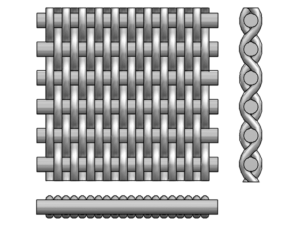

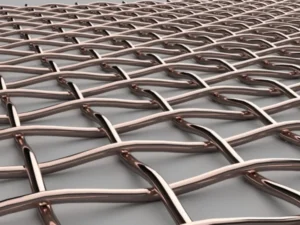

At its core, ultra fine wire mesh is precisely woven fabric made from extremely thin wires. These wires, often measured in microns (thousandths of a millimeter), are typically crafted from materials like stainless steel, nickel, copper, titanium, and various alloys. The weaving process itself is a highly specialized art, requiring advanced machinery and expertise to ensure consistent mesh size, wire spacing, and overall quality.

The defining characteristic of ultra fine wire mesh is its exceptionally small aperture size, or the opening between the wires. This is crucial for its primary function: precise filtration and separation.

Key Properties and Benefits:

The unique properties of ultra fine wire mesh make it a highly desirable material:

- Precise Filtration: This is the most prominent benefit. The consistent and minute aperture sizes allow for the separation of incredibly fine particles, making it ideal for applications requiring high levels of purity.

- High Strength-to-Weight Ratio: Despite being incredibly thin, the interwoven structure provides surprising strength and durability, especially when fabricated into layered structures.

- Large Surface Area: The intricate wire arrangement creates a large surface area within a small volume, enhancing chemical reactivity and filtration efficiency.

- Corrosion Resistance: Depending on the material used, ultra fine wire mesh can be highly resistant to corrosion from various chemicals and environmental factors, ensuring longevity and reliability in demanding applications.

- Controlled Permeability: The mesh’s pore size and density can be tailored to control the flow of fluids or gases, making it useful in applications requiring controlled diffusion or gas exchange.

- Electrical Conductivity: Certain materials like copper and stainless steel offer excellent electrical conductivity, enabling the use of ultra fine wire mesh in electronic and sensor applications.

- Flexibility and Formability: While strong, it can be formed and molded into various shapes, making it adaptable to different design requirements.

Applications Across Industries:

The versatility of ultra fine wire mesh has led to its widespread adoption in numerous industries:

- Aerospace: In aircraft fuel filters, hydraulic systems, and cabin air purification, ensuring reliability and performance.

- Medical: For sterilizing filters, drug delivery systems, and implantable devices where biocompatibility and precise filtration are paramount.

- Pharmaceutical: Essential for separating active ingredients, removing impurities, and ensuring the purity of drug formulations.

- Chemical Processing: Used in catalytic converters, process filtration, and separation of chemical compounds.

- Electronics: Employed in electromagnetic interference (EMI) shielding, microelectronics packaging, and battery components.

- Food and Beverage: Used in food processing filters, beverage clarification, and sanitization processes.

- Water Treatment: Applied in reverse osmosis membranes, wastewater treatment, and drinking water filtration, removing microscopic contaminants.

- Fuel Cells: Acts as a catalyst support and gas diffusion layer, promoting efficient energy conversion.

The Future of Ultra Fine Wire Mesh:

The demand for ultra fine wire mesh is projected to grow steadily as industries continue to push the boundaries of precision and efficiency. Emerging applications include:

- Advanced Battery Technology: In lithium-ion batteries and other energy storage devices, improving conductivity and energy density.

- Microfluidics: Fabricating microchannels and devices for drug discovery, diagnostics, and lab-on-a-chip applications.

- Environmental Sensors: Developing miniaturized sensors for air and water quality monitoring.

- 3D Printing: As a reinforcement material in 3D printed composites, enhancing strength and structural integrity.

Conclusion:

Ultra fine wire mesh is far more than just a finely woven fabric. It is a sophisticated engineering material with exceptional properties that are driving innovation across industries. As technology advances, we can expect to see even more creative and impactful applications of this remarkable material, cementing its place as an essential component in a future driven by precision and efficiency.

Reviews

There are no reviews yet.