Description

Sintered Wire Mesh: A Deep Dive into its Functionality, Applications, and Advantages

Sintered wire mesh is a high-performance filtration and separation material that has gained significant popularity across various industries. Its unique construction and manufacturing process offer superior properties compared to traditional filter media, making it an indispensable component in numerous applications. This article will explore the intricacies of sintered wire mesh, covering its creation, inherent advantages, and diverse applications.

What is Sintered Wire Mesh?

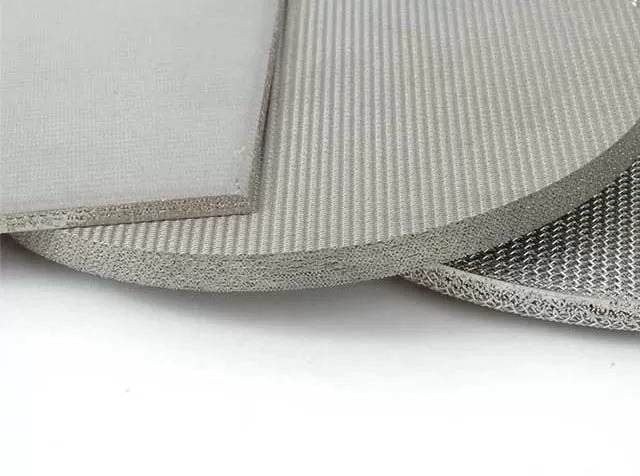

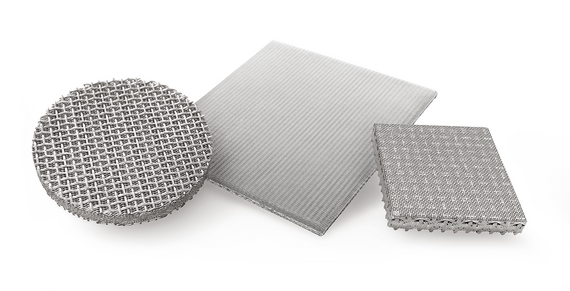

At its core, sintered wire mesh is a composite material formed by layering multiple layers of woven wire mesh together. These layers, each with specific properties like pore size and weave pattern, are then bonded together through a process called sintering. This involves heating the wire mesh under controlled conditions of temperature and pressure, causing the metal particles within the woven wires to fuse together at their contact points. This creates a robust, porous structure with excellent mechanical strength and consistent pore size distribution.

The Sintering Process: Giving Birth to a Versatile Material

The sintering process is critical to the performance and integrity of sintered wire mesh. Here’s a breakdown:

- Layering: Precisely woven wire mesh layers with varying specifications are carefully stacked on top of each other. These layers are often designed to perform specific functions such as filtration, diffusion, or support.

- Heating: The layered structure is then placed in a controlled atmosphere furnace and heated to a temperature close to the melting point of the metal used.

- Pressure Application: Simultaneously, pressure is applied to the structure, forcing the wire mesh layers into intimate contact.

- Diffusion Bonding: The heat and pressure encourage diffusion bonding, where atoms from adjacent wires diffuse across the interface, forming metallurgical bonds.

- Cooling: The structure is then slowly cooled, allowing the fused bonds to solidify, resulting in a strong and permanent porous structure.

The result is a solid, integrated material with a uniform pore structure, exceptional mechanical properties, and a high resistance to chemical and thermal degradation.

Advantages of Sintered Wire Mesh: The Key to its Popularity

Sintered wire mesh boasts a range of advantages over traditional filter media:

- High Strength and Durability: The sintering process creates strong metallurgical bonds, resulting in a highly durable material capable of withstanding high pressures, temperatures, and corrosive environments.

- Precise Pore Size Control: The layered structure and carefully controlled sintering process allow for precise control over pore size, ensuring consistent filtration performance.

- High Porosity and Permeability: The inherent porosity of the wire mesh, combined with the controlled pore size, leads to high permeability, allowing for efficient fluid flow and reduced pressure drop.

- Cleanable and Reusable: Due to its robust structure, sintered wire mesh can be cleaned and reused, reducing operational costs and environmental impact. Backwashing, ultrasonic cleaning, and chemical cleaning are common methods.

- Excellent Chemical Resistance: Sintered wire mesh can be manufactured from a variety of metals and alloys, offering excellent resistance to a wide range of chemicals and corrosive fluids.

- Temperature Resistance: The high-temperature sintering process allows the resulting mesh to withstand extreme temperatures, making it suitable for demanding applications.

- Customizable Design: Sintered wire mesh can be customized in terms of layer configuration, pore size, weave pattern, and material to meet specific application requirements.

Diverse Applications: Where Sintered Wire Mesh Shines

The exceptional properties of sintered wire mesh make it suitable for a wide range of applications across various industries:

- Filtration: The most common application of sintered wire mesh is filtration, including:

- Liquid Filtration: Removing particulate matter from liquids in chemical processing, pharmaceuticals, food and beverage, and water treatment.

- Gas Filtration: Filtering air and gases in industrial processes, oil and gas, and aerospace applications.

- Hydraulic Filtration: Removing contaminants from hydraulic fluids in machinery and equipment.

- Fluidization: Sintered wire mesh is used as a fluidization medium in chemical reactors and powder processing equipment, providing uniform gas distribution and preventing channeling.

- Diffusion: The controlled pore size and permeability of sintered wire mesh make it suitable for diffusion applications, such as gas sparging and distribution.

- Pressure Drop Control: In some applications, sintered wire mesh is used to control pressure drop in fluid systems, ensuring optimal flow rates and performance.

- Flame Arrestors: Sintered wire mesh can be used as a flame arrestor in flammable gas and liquid applications, preventing the propagation of flames.

- Silencers: The porous structure of sintered wire mesh can be used to absorb sound waves, making it suitable for noise reduction applications.

- Medical Devices: Sintered wire mesh is used in medical devices such as filters for blood transfusions and implantable devices.

Conclusion: A Versatile Material for a Demanding World

Sintered wire mesh is a high-performance material that offers a compelling combination of strength, durability, and precise filtration capabilities. Its unique manufacturing process and customizable design make it a versatile solution for a wide range of challenging applications. As industries continue to demand more efficient and reliable filtration and separation technologies, sintered wire mesh is poised to play an increasingly important role in shaping the future of these processes. Its ability to withstand extreme conditions, provide consistent performance, and offer long-term cost savings makes it an indispensable component in countless applications around the globe.

Reviews

There are no reviews yet.