Description

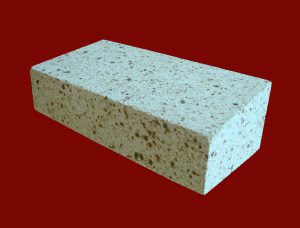

Sillimanite Bricks: The Unsung Heroes of High-Temperature Industries

In the realm of high-temperature industrial processes, where intense heat and corrosive environments reign supreme, the materials used must be exceptionally robust. Among these silent guardians, Sillimanite bricks stand out as reliable and indispensable components, contributing to the efficiency and longevity of various crucial industries.

What are Sillimanite Bricks?

Sillimanite bricks are a type of high-alumina refractory brick characterized by their primary constituent: Sillimanite (Al₂SiO₅). This naturally occurring aluminosilicate mineral imparts exceptional properties to the finished brick, making it highly sought after in demanding applications. While naturally occurring sillimanite is used, these bricks are often manufactured by combining other aluminosilicate materials like kyanite or andalusite that convert to sillimanite during the firing process.

Key Properties and Advantages:

The remarkable performance of sillimanite bricks stems from their unique combination of properties:

- Exceptional Refractoriness: They possess a high softening point and can withstand prolonged exposure to extreme temperatures without significant deformation or degradation. This is critical for maintaining structural integrity within high-temperature furnaces and kilns.

- High Load-Bearing Capacity at High Temperatures: Unlike many other refractory materials, sillimanite bricks retain their strength and load-bearing capacity even when subjected to intense heat. This allows them to support heavy loads within industrial infrastructure.

- Excellent Resistance to Thermal Shock: Sudden temperature fluctuations are common in industrial settings. Sillimanite bricks exhibit excellent resistance to thermal shock, preventing cracking, spalling, and premature failure due to rapid heating or cooling.

- Good Chemical Inertness: Sillimanite is chemically resistant to many acidic and alkaline substances, extending the lifespan of the bricks in corrosive environments. This makes them ideal for applications involving molten metals, slags, and other aggressive chemicals.

- Low Thermal Expansion: Their low thermal expansion coefficient minimizes dimensional changes with temperature variations, preventing stresses and ensuring a stable and durable lining.

- Abrasion Resistance: The inherent hardness of sillimanite imparts good abrasion resistance, making these bricks suitable for applications where they are exposed to particulate matter or mechanical wear.

Applications Across Diverse Industries:

The unique properties of sillimanite bricks make them indispensable in a wide range of industries:

- Steel Industry: Used for lining blast furnaces, ladles, and other high-temperature equipment involved in steel production.

- Glass Industry: Employed in glass melting furnaces and forehearths, where they resist the corrosive effects of molten glass.

- Cement Industry: Utilized in the construction of rotary kilns and preheaters, withstanding the extreme temperatures and abrasive conditions of cement production.

- Ceramic Industry: Used to build kilns for firing bricks, tiles, and other ceramic products.

- Non-Ferrous Metal Production: Employed in furnaces for smelting and refining non-ferrous metals like aluminum and copper.

- Chemical Industry: Used for lining reactors and other vessels where high temperatures and corrosive chemicals are present.

- Power Generation: Employed in boilers and incinerators to withstand high temperatures and resist slag attack.

Looking Ahead: Innovation and Sustainability:

The future of sillimanite bricks lies in continued innovation and a growing focus on sustainability. Research and development efforts are focused on:

- Improving Manufacturing Processes: Exploring energy-efficient and environmentally friendly manufacturing methods to reduce the carbon footprint of brick production.

- Optimizing Composition: Investigating new additive materials and processing techniques to further enhance the performance characteristics of sillimanite bricks.

- Developing Recycling Strategies: Exploring methods for recycling used refractory bricks to minimize waste and conserve natural resources.

Conclusion:

Sillimanite bricks are more than just building materials; they are the foundation upon which numerous high-temperature industries operate. Their exceptional properties, durability, and reliability make them indispensable components for ensuring the efficiency, safety, and longevity of critical industrial processes. As industries continue to evolve and demand increasingly robust materials, sillimanite bricks will undoubtedly remain a cornerstone of high-temperature applications for years to come. Their continued development and adaptation will play a vital role in shaping the future of these essential industries.

Reviews

There are no reviews yet.