Description

Pour Point Depressants: Keeping Fuels Flowing in the Cold

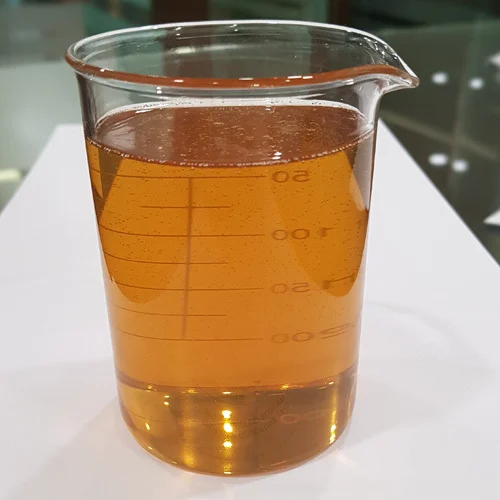

Imagine trying to start your car on a frigid winter morning, only to find that the fuel has turned into a thick, waxy gel. That’s the nightmare scenario that pour point depressants (PPDs) are designed to prevent. These unsung heroes of the fuel industry play a critical role in ensuring the operability of vehicles and machinery in cold weather conditions.

What is Pour Point?

Before diving into PPDs, understanding the concept of “pour point” is crucial. The pour point of a liquid, particularly fuels like diesel and crude oil, is the lowest temperature at which it will still flow when cooled under prescribed conditions. Below this temperature, paraffin wax crystals begin to form and interlock, hindering fluid movement and leading to gelling. This can clog fuel lines, filters, and injectors, rendering equipment useless.

The Role of Pour Point Depressants

Pour point depressants are additives that modify the wax crystal formation process in fuels, preventing them from gelling at low temperatures. They work by:

- Interfering with Wax Crystal Growth: PPDs typically consist of long, branched-chain polymer molecules. These molecules co-crystallize with the wax crystals, disrupting their orderly growth. This prevents the formation of large, interlocking structures that cause gelling.

- Reducing Wax Crystal Size: By disrupting the crystallization process, PPDs promote the formation of smaller, more dispersed wax crystals. These smaller crystals are less likely to clump together and impede fuel flow.

- Modifying Wax Crystal Shape: Some PPDs can even alter the shape of the wax crystals, making them less prone to interlocking and forming a gel.

Types of Pour Point Depressants

Several types of PPDs are available, each with its own strengths and weaknesses, and best suited for different types of fuels and temperature ranges. Some common types include:

- Polyalkyl Methacrylates (PAMAs): These are widely used and effective in a variety of fuels. Their performance can be tailored by adjusting the alkyl chain length and monomer composition.

- Ethylene-Vinyl Acetate (EVA) Copolymers: These are often preferred for their cost-effectiveness and good performance in middle distillates like diesel fuel.

- Olefin Copolymers: These are particularly effective in highly paraffinic crude oils and heavy fuels.

- Polar Nitrogen Containing Compounds: Used in smaller dosages than the aforementioned additives, can have additional benefits like corrosion inhibition.

Factors Affecting PPD Effectiveness

The effectiveness of a PPD depends on various factors, including:

- Fuel Composition: The type and amount of paraffin wax present in the fuel significantly impact PPD performance. Fuels with higher paraffin content may require more PPD or a more potent type.

- Temperature Profile: The rate and extent of cooling can affect wax crystal formation and, consequently, PPD effectiveness.

- PPD Concentration: The concentration of PPD must be optimized for the specific fuel and operating conditions. Too little PPD may not be effective, while too much can sometimes worsen the pour point or cause other issues.

- Fuel Additive Compatability: Some fuel additives can react with (or neutralize) the PPD, thereby diminishing their effectiveness.

Benefits of Using Pour Point Depressants

The benefits of using PPDs are substantial:

- Improved Cold Weather Operability: They ensure that fuels remain fluid and usable in cold climates, preventing equipment downtime and related costs.

- Enhanced Fuel Efficiency: By preventing fuel gelling, PPDs ensure proper fuel atomization and combustion, leading to improved fuel efficiency.

- Reduced Maintenance Costs: Preventing fuel system clogs reduces the need for costly repairs and maintenance.

- Wider Availability of Fuels: PPDs allow refineries to blend and utilize a wider range of crude oils, including those with higher paraffin content.

Conclusion

Pour point depressants are essential additives for fuels used in cold climates. They play a vital role in maintaining the operability of vehicles and machinery by preventing fuel gelling and ensuring smooth fuel flow. By understanding the science behind PPDs and their impact on fuel properties, we can appreciate their importance in modern fuel technology and their contribution to a more reliable and efficient transportation system. The continuing development and refinement of new and improved PPDs will undoubtedly play a crucial role in meeting the future challenges of cold weather fuel performance.

Reviews

There are no reviews yet.