Description

Polyvinylidene Fluoride (PVDF): A Versatile Polymer Powerhouse

Polyvinylidene Fluoride, commonly known as PVDF, is a highly non-reactive thermoplastic fluoropolymer revered for its exceptional chemical resistance, thermal stability, and piezoelectric properties. Its unique combination of attributes has made it a material of choice across a diverse range of industries, from construction and chemical processing to electronics and biomedicine.

What is PVDF?

PVDF is a semi-crystalline polymer composed of repeating units of vinylidene fluoride (CH2CF2). The presence of fluorine atoms in its structure is key to its exceptional properties. These fluorine atoms create strong carbon-fluorine bonds, leading to its inherent resistance to degradation from chemicals, solvents, and UV radiation.

Key Properties and Advantages:

- Exceptional Chemical Resistance: PVDF exhibits remarkable resistance to a wide array of aggressive chemicals, including acids, bases, solvents, and oxidizing agents. This makes it ideal for applications where exposure to harsh environments is common.

- High Thermal Stability: PVDF maintains its mechanical integrity over a broad temperature range, typically from -40°C to 150°C, making it suitable for both high and low-temperature applications.

- Piezoelectric Properties: PVDF is a piezoelectric material, meaning it generates an electrical charge when subjected to mechanical stress or pressure. This property is harnessed in sensors, actuators, and energy harvesting devices.

- High Mechanical Strength: Despite its flexibility, PVDF boasts impressive tensile strength and impact resistance, making it durable and long-lasting in demanding applications.

- UV Resistance: PVDF demonstrates excellent resistance to degradation from ultraviolet radiation, ensuring its longevity in outdoor applications.

- Low Permeability: Its low permeability to gases and liquids makes it an effective barrier material in various applications.

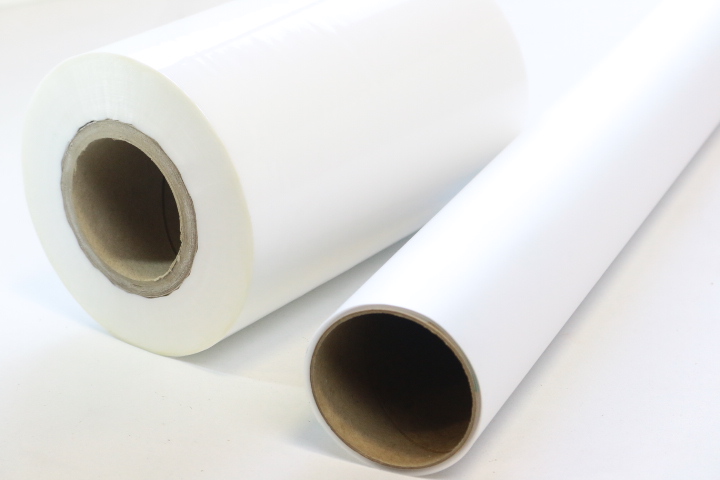

- Ease of Processing: PVDF can be processed using various methods, including extrusion, injection molding, and film casting, allowing for the creation of complex shapes and designs.

Applications Across Industries:

The versatile properties of PVDF have led to its widespread adoption in various industries:

- Chemical Processing: PVDF is utilized as a lining for tanks, pipes, and valves in chemical processing plants, ensuring the safe and reliable handling of corrosive chemicals.

- Construction: PVDF coatings are applied to architectural fabrics, metal panels, and roofing materials to enhance their resistance to weathering, UV degradation, and chemical attack.

- Electronics: PVDF films are employed in sensors, actuators, and energy harvesting devices due to their piezoelectric properties. They are also found in capacitors and other electronic components.

- Biomedicine: PVDF membranes are used in medical filtration applications, such as hemodialysis and protein purification. Its biocompatibility also makes it suitable for implantable devices and drug delivery systems.

- Energy: PVDF is used in lithium-ion batteries as a binder for the electrode materials. Its chemical stability and electrochemical properties contribute to the battery’s performance and lifespan.

- Water Treatment: PVDF membranes are used extensively in membrane filtration processes, such as microfiltration and ultrafiltration, for water purification and wastewater treatment.

Looking Ahead:

Ongoing research and development are focused on further enhancing the properties and expanding the applications of PVDF. This includes exploring new processing techniques, developing PVDF-based composites with improved performance, and investigating its potential in emerging fields such as flexible electronics and bioelectronics.

Conclusion:

Polyvinylidene Fluoride (PVDF) stands as a versatile and high-performance polymer with a remarkable combination of properties. Its exceptional chemical resistance, thermal stability, and piezoelectric capabilities have made it an indispensable material in a wide range of industries. As innovation continues to drive advancements in materials science, PVDF is poised to play an even more significant role in shaping the future of technology and engineering.

Reviews

There are no reviews yet.