Description

Polysulfone (PSU): A Tough and Versatile Thermoplastic

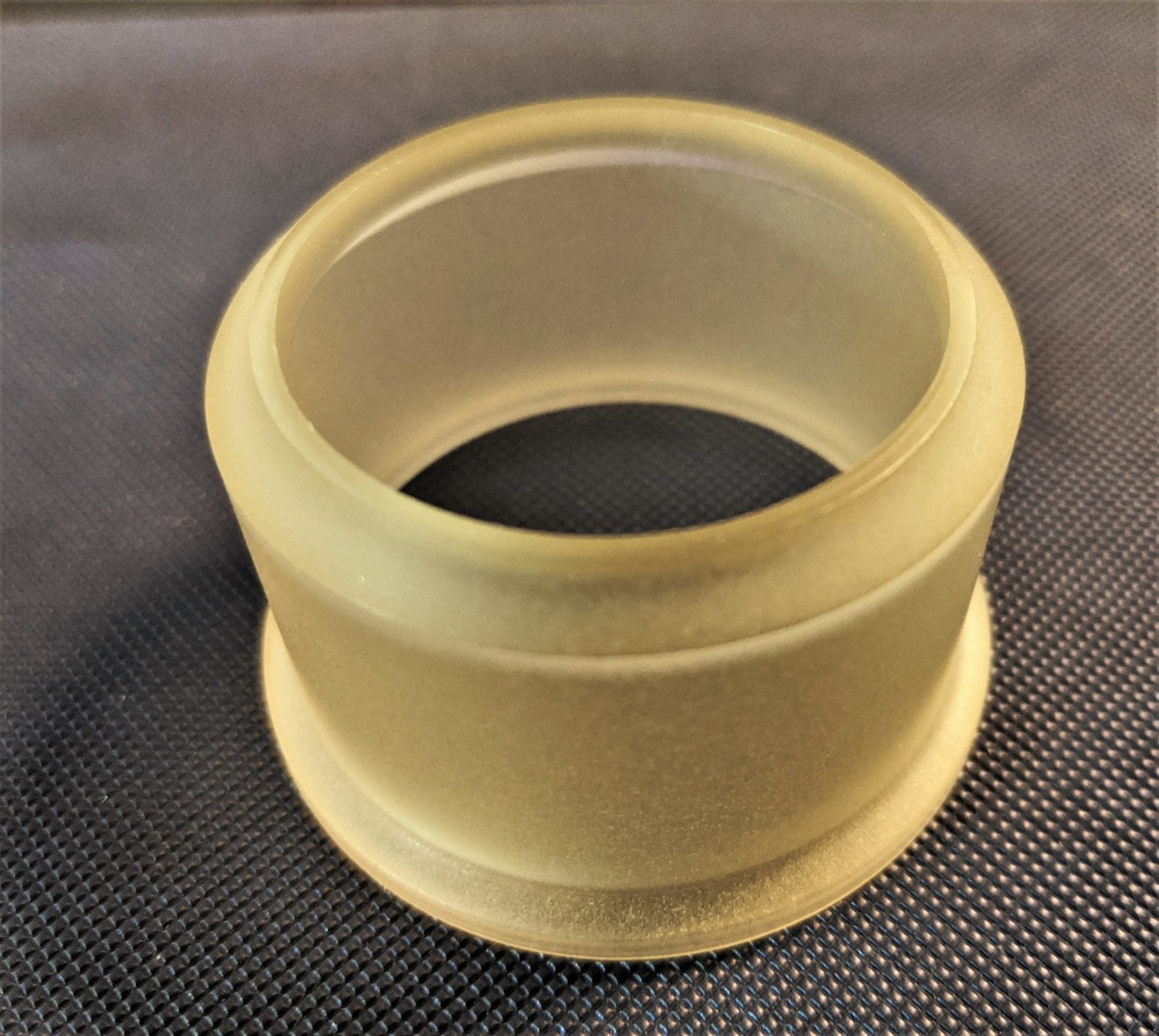

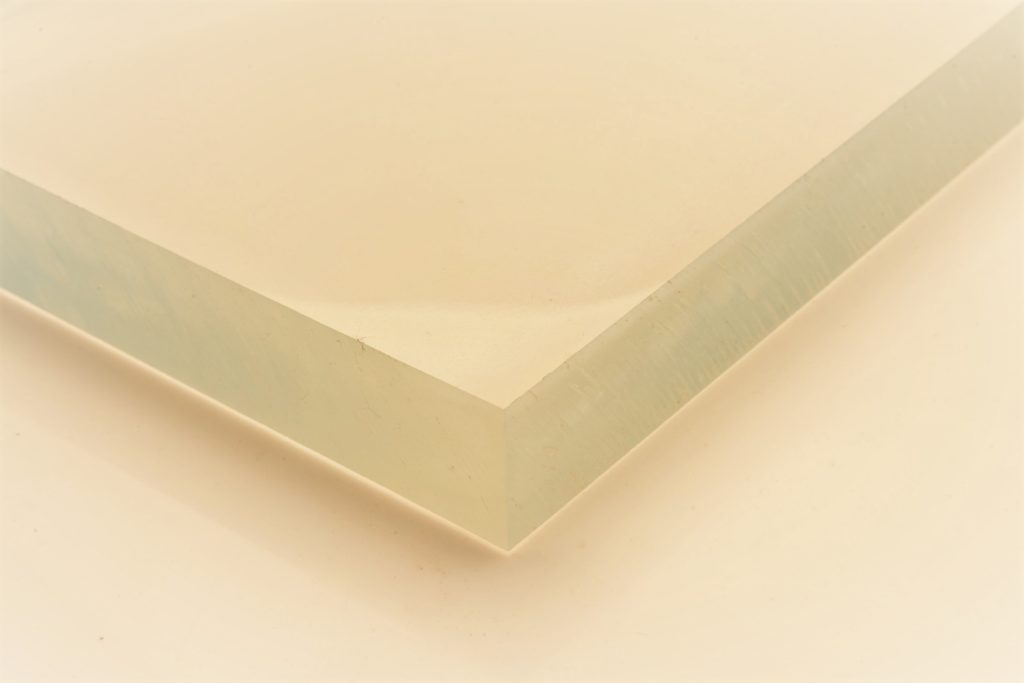

Polysulfone (PSU) is a high-performance thermoplastic known for its exceptional strength, thermal stability, and chemical resistance. This amorphous polymer has found applications in diverse industries, from medical devices to automotive components, thanks to its unique combination of properties. Let’s delve into the world of polysulfone and explore its characteristics, advantages, and common uses.

What is Polysulfone?

Polysulfone is a member of the sulfone polymer family, characterized by the presence of sulfone groups (SO₂) in its repeating unit. This chemical structure contributes significantly to its properties, making it a robust and reliable material. PSU is typically manufactured through a polycondensation reaction involving bisphenol A and 4,4′-dichlorodiphenyl sulfone.

Key Properties of Polysulfone:

- High Strength and Rigidity: PSU exhibits excellent tensile strength, flexural strength, and stiffness, allowing it to withstand significant loads and maintain its shape under stress.

- Thermal Stability: One of the standout features of polysulfone is its ability to retain its properties at elevated temperatures. It has a high glass transition temperature (Tg) around 190°C (374°F), meaning it can withstand continuous use at temperatures well above the boiling point of water.

- Chemical Resistance: PSU is resistant to a wide range of chemicals, including acids, alkalis, and aliphatic hydrocarbons. This makes it suitable for use in harsh environments where exposure to corrosive substances is common.

- Hydrolytic Stability: Unlike some other polymers, polysulfone is resistant to degradation from hydrolysis, making it suitable for applications involving exposure to water or steam.

- Transparency: Polysulfone is naturally transparent, allowing for visual inspection of components and products. This characteristic is particularly valuable in medical and laboratory applications.

- Good Electrical Properties: PSU has good dielectric strength and insulation properties, making it suitable for electrical components and applications.

- Flame Resistance: Polysulfone is inherently flame retardant and meets many industry standards for flammability.

Advantages of Using Polysulfone:

- Long-Term Durability: Its combination of strength, thermal stability, and chemical resistance ensures a long service life for components made from PSU.

- Sterilizability: Polysulfone can withstand repeated sterilization cycles using various methods, including autoclaving, making it ideal for medical devices and equipment.

- Versatility: Its properties allow it to be used in a wide array of applications across different industries.

- Lightweight: Compared to metals, polysulfone offers a lighter weight alternative without sacrificing significant strength.

- Easy Processing: PSU can be processed using various methods, including injection molding, extrusion, and thermoforming, making it readily adaptable to different manufacturing processes.

Common Applications of Polysulfone:

The unique properties of polysulfone make it a popular choice for a wide range of applications, including:

- Medical Devices: Sterilization trays, surgical instruments, dental equipment, and dialysis membranes.

- Food and Beverage Industry: Food trays, microwaveable containers, and components for beverage dispensing systems.

- Automotive Industry: Connectors, fuel cells, and components for fluid handling systems.

- Electronics Industry: Circuit boards, connectors, and insulators.

- Aerospace Industry: Interior components, structural parts, and wire insulation.

- Membrane Technology: Water filtration membranes, gas separation membranes, and dialysis membranes.

- Piping and Plumbing: Fittings, valves, and pipes for handling hot water and chemicals.

Conclusion:

Polysulfone is a versatile and high-performing thermoplastic that offers a compelling combination of strength, thermal stability, and chemical resistance. Its ability to withstand harsh environments and repeated sterilization cycles makes it an ideal material for demanding applications, particularly in the medical, food and beverage, and automotive industries. As technology continues to advance, polysulfone is expected to play an increasingly important role in various sectors, contributing to the development of innovative and reliable products.

Reviews

There are no reviews yet.