Description

Polypropylene (PP): The Versatile Polymer Shaping Our World

Polypropylene (PP), a thermoplastic polymer known for its versatility, durability, and cost-effectiveness, has become a ubiquitous material in a wide range of applications. From packaging and textiles to automotive parts and medical devices, PP’s adaptability has cemented its place as one of the most widely used plastics globally.

Understanding Polypropylene’s Properties:

PP’s success stems from its unique combination of advantageous properties:

- High Strength and Rigidity: PP exhibits excellent tensile strength and stiffness, making it suitable for structural applications where load-bearing capability is crucial.

- Chemical Resistance: It is highly resistant to many solvents, acids, and bases, making it ideal for containers and pipes used in chemical processing and storage.

- Moisture Resistance: PP is hydrophobic, meaning it doesn’t readily absorb water. This makes it perfect for outdoor applications and packaging that needs to protect contents from moisture.

- Heat Tolerance: PP can withstand relatively high temperatures compared to other common plastics like polyethylene (PE), allowing for applications involving hot liquids or sterilization.

- Lightweight: Its low density contributes to fuel efficiency in transportation applications and makes it easy to handle in packaging and storage.

- Recyclability: PP is recyclable and can be reprocessed into new products, contributing to a more sustainable lifecycle.

Diverse Applications Across Industries:

The versatile nature of PP allows it to be tailored for a multitude of applications:

- Packaging: PP is extensively used in food packaging, beverage containers, and consumer goods packaging due to its chemical resistance, moisture barrier properties, and ability to be molded into various shapes. Examples include yogurt containers, bottle caps, and flexible films.

- Automotive: PP is increasingly used in automotive components, such as bumpers, interior trim, battery casings, and door panels, due to its lightweight nature, impact resistance, and ability to be molded into complex shapes.

- Textiles: PP fibers are used in carpets, upholstery, ropes, and nonwoven fabrics due to their strength, resistance to staining, and low moisture absorption.

- Medical: PP is used in medical devices, syringes, packaging for pharmaceuticals, and laboratory equipment due to its biocompatibility, sterilizability, and resistance to chemical corrosion.

- Consumer Goods: PP finds applications in a wide range of consumer products, including toys, furniture, appliances, and storage containers.

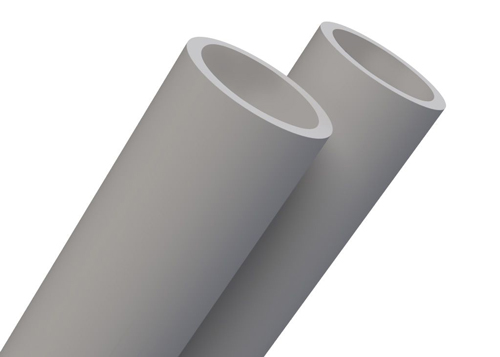

- Industrial: PP is used in pipes, tanks, and other industrial components due to its chemical resistance and durability.

Different Forms of Polypropylene:

PP is available in various forms, each offering specific properties:

- Homopolymer PP: The most common type, offering high stiffness and tensile strength.

- Copolymer PP: Contains other monomers, such as ethylene, to improve impact resistance and flexibility.

- Random Copolymer PP: Offers improved clarity and flexibility compared to homopolymer PP.

- Impact Copolymer PP: Designed for high impact resistance, even at low temperatures.

Sustainability and the Future of PP:

While PP is recyclable, the infrastructure for its recycling is still developing in many regions. Efforts are being made to improve recycling rates and develop innovative technologies for converting PP waste into new products. Furthermore, research is underway to develop bio-based PP alternatives from sustainable resources.

Conclusion:

Polypropylene’s remarkable properties have made it an indispensable material in countless industries. Its versatility, strength, chemical resistance, and cost-effectiveness ensure its continued importance in shaping our world. As technology advances and environmental concerns grow, ongoing efforts to improve PP recycling and develop sustainable alternatives will further solidify its position as a vital polymer for years to come.

Reviews

There are no reviews yet.