Description

Polyoxymethylene (POM): A Versatile Engineering Plastic for High-Performance Applications

Polyoxymethylene (POM), also known as acetal, is a high-performance engineering thermoplastic widely used in a diverse range of applications. Its exceptional combination of properties, including high stiffness, strength, and dimensional stability, makes it a preferred choice for engineers and manufacturers seeking reliable and durable materials. This article delves into the key characteristics of POM, its various types, typical applications, and important considerations for its use.

What is Polyoxymethylene (POM)?

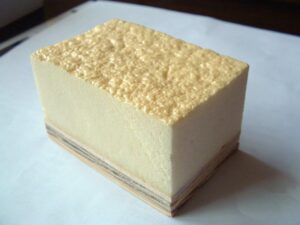

POM is a semi-crystalline polymer derived from formaldehyde. Its repeating unit (-CH2O-) gives it a characteristic structure and contributes to its inherent strength and rigidity. Two main types of POM exist:

- Homopolymer POM (Delrin®): Offers superior mechanical strength, stiffness, and resistance to creep and fatigue. It exhibits higher crystallinity and a more ordered structure compared to copolymer POM.

- Copolymer POM (Celcon®): Provides improved thermal stability, chemical resistance, and processability. The introduction of comonomers disrupts the regularity of the polymer chain, enhancing these properties.

Both homopolymer and copolymer POM are available in various grades, each tailored to specific performance requirements.

Key Properties of POM:

POM’s popularity stems from its impressive array of properties, including:

- High Stiffness and Strength: POM exhibits exceptional resistance to deformation under load, making it suitable for structural components and load-bearing applications.

- Excellent Dimensional Stability: POM maintains its shape and size even under varying temperatures and humidity levels, crucial for precision parts.

- Low Coefficient of Friction: Its inherent lubricity reduces friction and wear, making it ideal for gears, bearings, and sliding components.

- Good Chemical Resistance: POM resists a wide range of solvents, fuels, and chemicals, enhancing its durability in harsh environments.

- Good Creep Resistance: POM can withstand sustained stress without significant deformation over time.

- Ease of Processing: POM can be readily processed using typical thermoplastic molding techniques such as injection molding and extrusion.

- Good Wear Resistance: POM demonstrates excellent resistance to abrasion and wear, extending the lifespan of components.

Applications of POM:

The versatile properties of POM make it a suitable material for a wide range of applications across various industries, including:

- Automotive: Fuel system components, interior trim, gears, bearings, door handle mechanisms.

- Consumer Products: Zippers, buckles, appliance parts, toys, pen bodies.

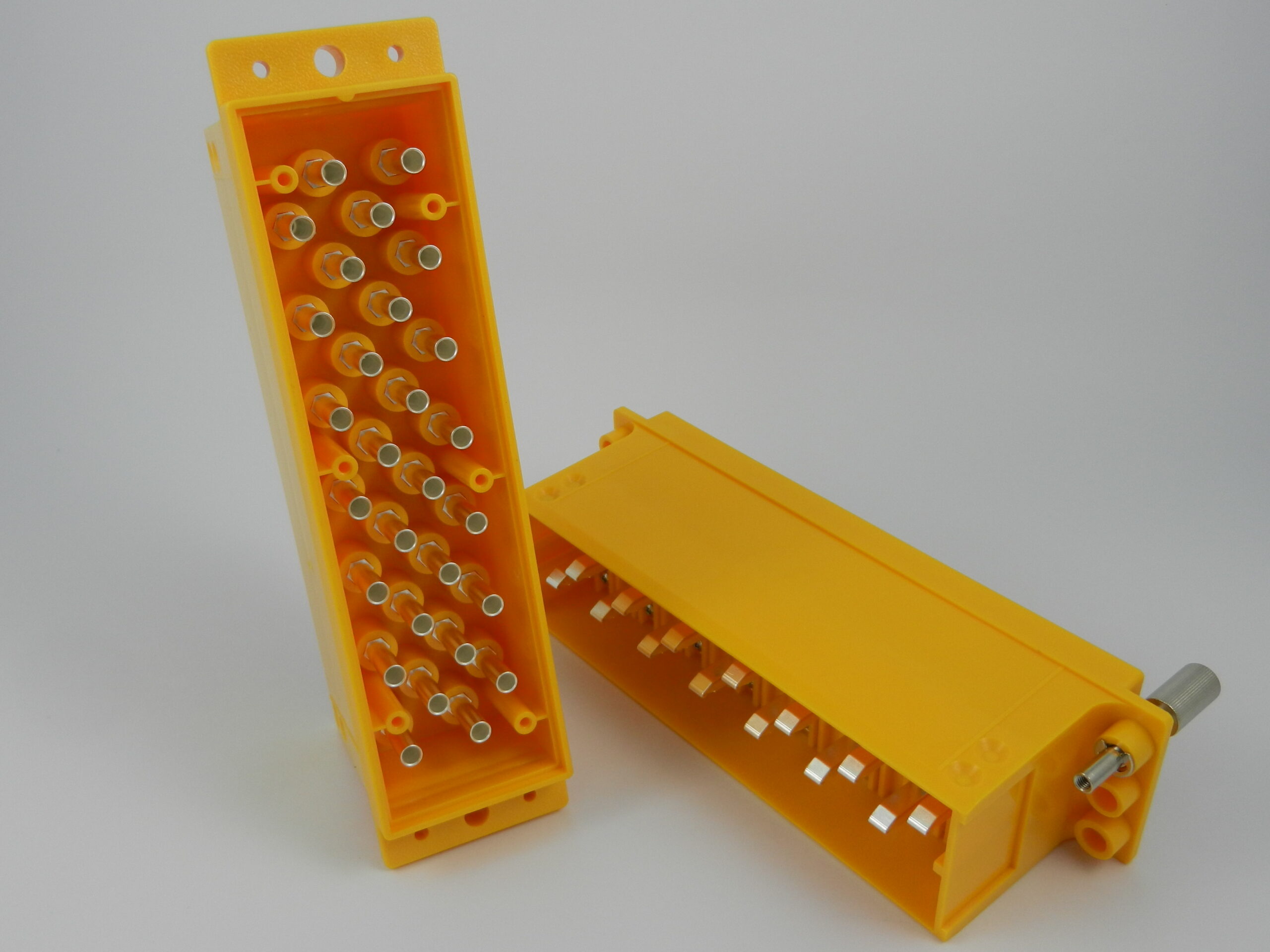

- Electronics: Connectors, switches, housings, gears for CD/DVD drives.

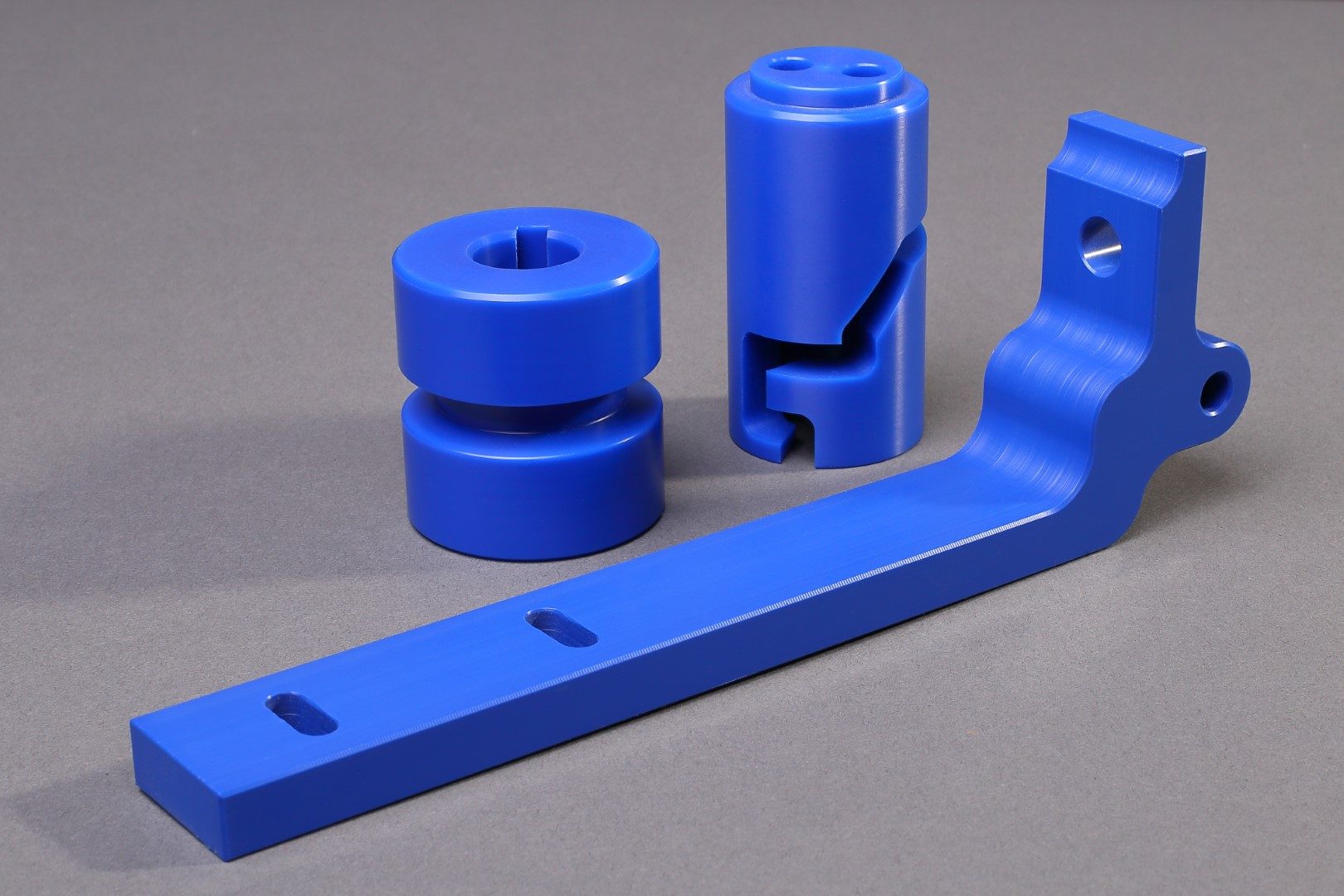

- Industrial: Gears, bearings, bushings, rollers, pump components, conveyor rollers.

- Medical: Surgical instruments, inhalers, dental applications (limited biocompatibility requirements).

- Plumbing: Faucets, valves, fittings.

Considerations for Using POM:

While POM offers numerous advantages, certain factors must be considered for its successful implementation:

- Limited Resistance to Strong Acids and Bases: POM can be degraded by prolonged exposure to strong acids and bases.

- Flammability: POM is flammable and may require flame retardant additives for certain applications.

- Shrinkage: POM exhibits shrinkage during molding, which must be considered in part design and mold design.

- UV Degradation: Prolonged exposure to ultraviolet (UV) radiation can degrade POM, necessitating UV stabilizers for outdoor applications.

- Molding Temperature: Proper process control during molding is essential to avoid degradation and achieve optimal performance.

- Price: POM can be more expensive than some commodity plastics, requiring a cost-benefit analysis for specific applications.

Conclusion:

Polyoxymethylene (POM) is a valuable engineering plastic that offers a unique balance of strength, stiffness, dimensional stability, and chemical resistance. Its versatility enables its use in a wide array of applications, making it a vital material for engineers and designers seeking high-performance solutions. By understanding its key properties, limitations, and proper processing techniques, engineers can effectively leverage POM to create durable, reliable, and long-lasting products. As technology advances, POM continues to be refined and adapted to meet the evolving demands of modern industries, solidifying its position as a leading engineering thermoplastic.

Reviews

There are no reviews yet.